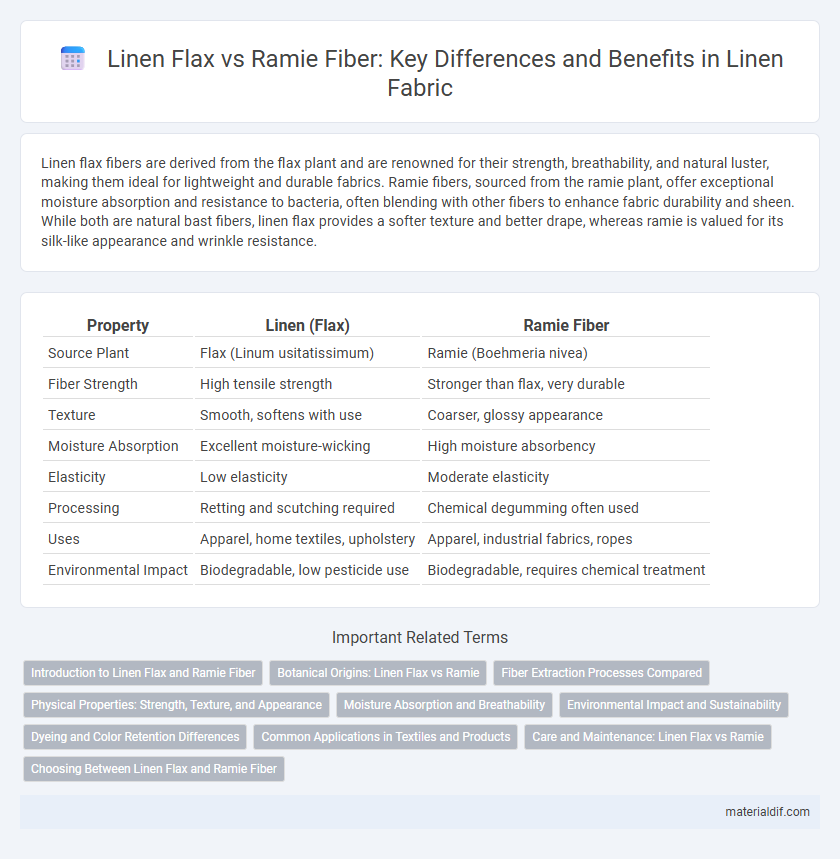

Linen flax fibers are derived from the flax plant and are renowned for their strength, breathability, and natural luster, making them ideal for lightweight and durable fabrics. Ramie fibers, sourced from the ramie plant, offer exceptional moisture absorption and resistance to bacteria, often blending with other fibers to enhance fabric durability and sheen. While both are natural bast fibers, linen flax provides a softer texture and better drape, whereas ramie is valued for its silk-like appearance and wrinkle resistance.

Table of Comparison

| Property | Linen (Flax) | Ramie Fiber |

|---|---|---|

| Source Plant | Flax (Linum usitatissimum) | Ramie (Boehmeria nivea) |

| Fiber Strength | High tensile strength | Stronger than flax, very durable |

| Texture | Smooth, softens with use | Coarser, glossy appearance |

| Moisture Absorption | Excellent moisture-wicking | High moisture absorbency |

| Elasticity | Low elasticity | Moderate elasticity |

| Processing | Retting and scutching required | Chemical degumming often used |

| Uses | Apparel, home textiles, upholstery | Apparel, industrial fabrics, ropes |

| Environmental Impact | Biodegradable, low pesticide use | Biodegradable, requires chemical treatment |

Introduction to Linen Flax and Ramie Fiber

Linen flax and ramie fiber are two natural plant-based fibers known for their durability and breathability. Linen flax, derived from the flax plant (Linum usitatissimum), is prized for its strength, moisture-wicking properties, and smooth texture, making it ideal for high-quality textiles. Ramie fiber, extracted from the stalks of the ramie plant (Boehmeria nivea), offers exceptional luster, resistance to bacterial growth, and blends well with other fibers, commonly used in apparel and home textiles.

Botanical Origins: Linen Flax vs Ramie

Linen fiber is derived from the fibers of the flax plant (Linum usitatissimum), a member of the Linaceae family native to the temperate regions of Europe and Western Asia. Ramie fiber originates from the stalks of the Ramie plant (Boehmeria nivea), part of the Urticaceae family, commonly found in Eastern Asia. Both fibers are bast fibers extracted from the inner bark, but their botanical classifications highlight distinct plant families and geographic origins crucial in textile applications.

Fiber Extraction Processes Compared

Linen flax fiber extraction involves retting, a natural or chemical process that breaks down the pectin binding the fibers to the stem, followed by scutching and hackling to separate and smooth the fibers. Ramie fiber extraction relies on enzymatic degumming and mechanical decortication, which remove the gummy substances surrounding the fibers without extensive retting, resulting in a stronger, silkier fiber. The flax retting process is more time-consuming and environmentally dependent, whereas ramie's enzymatic extraction offers a faster, more consistent method but requires precise chemical control.

Physical Properties: Strength, Texture, and Appearance

Linen flax fiber exhibits superior tensile strength, making it highly durable and ideal for robust textile applications, while ramie fiber, though strong, is more brittle and prone to breaking under stress. The texture of flax is smooth and somewhat coarse, providing a firm feel with natural luster, whereas ramie offers a silkier, shinier surface with a finer, more delicate hand. In appearance, flax fibers present a matte finish with a slightly beige tone, contrasting with ramie's glossy white color that enhances its aesthetic appeal in luxury fabrics.

Moisture Absorption and Breathability

Linen flax fiber exhibits superior moisture absorption and breathability compared to ramie fiber, making it ideal for warm climates and active wear. Flax fibers can absorb up to 12-13% of their weight in moisture without feeling damp, promoting comfort by wicking sweat away from the skin. Ramie fiber, while breathable, has slightly lower moisture retention, leading to less effective sweat management in textile applications.

Environmental Impact and Sustainability

Linen flax and ramie fiber both offer sustainable textile options, but linen flax typically has a lower environmental impact due to its natural biodegradability and minimal need for pesticides or fertilizers during cultivation. Ramie fiber requires more intensive chemical processing to extract fibers, which can increase pollution and energy consumption, although it benefits from strong durability and moisture resistance. Choosing linen flax supports eco-friendly practices by promoting soil health and reducing water usage compared to the more resource-intensive processing of ramie.

Dyeing and Color Retention Differences

Linen flax fibers exhibit superior dye absorption and color retention due to their porous cell structure and natural pectin content, resulting in vibrant and long-lasting hues. Ramie fibers, while strong and lustrous, have a smoother surface and higher lignin content that makes dye penetration more challenging, often requiring mordants to achieve comparable color fastness. Consequently, linen flax is preferred for textiles demanding rich saturation and durability of dyes in both natural and synthetic dye applications.

Common Applications in Textiles and Products

Linen flax fibers are predominantly used in high-quality apparel, home textiles, and upholstery due to their breathability, strength, and natural luster. Ramie fibers, known for their silky sheen and durability, are commonly blended with cotton or wool in garments, industrial fabrics, and decorative textiles. Both fibers contribute to eco-friendly and sustainable products, with flax favored in traditional linen fabrics and ramie in lightweight, wrinkle-resistant textiles.

Care and Maintenance: Linen Flax vs Ramie

Linen flax fibers require gentle washing with mild detergents and should be air-dried to maintain their natural strength and softness, avoiding high heat that can cause shrinkage or damage. Ramie fiber is more resistant to mildew and does not weaken as easily when exposed to sunlight, making it easier to clean and dry quickly without losing durability. Both fibers benefit from ironing while damp to preserve smoothness, but linen flax demands more careful handling due to its susceptibility to wear over time.

Choosing Between Linen Flax and Ramie Fiber

Linen flax and ramie fiber are both natural fibers valued for their strength and breathability, but linen flax offers superior wrinkle resistance and a softer texture, making it ideal for clothing and home textiles. Ramie fiber is highly durable and moisture-resistant, often chosen for upholstery and industrial fabrics due to its resistance to rotting and microbial attack. When selecting between the two, prioritize linen flax for comfort and aesthetic appeal, while ramie fiber suits applications demanding enhanced durability and moisture management.

Linen Flax vs Ramie Fiber Infographic

materialdif.com

materialdif.com