Oil-tanned leather offers superior durability and water resistance, making it ideal for pet accessories exposed to outdoor conditions. Water-tanned leather provides a softer, more supple texture, enhancing comfort but with less protection against moisture. Choosing between oil-tanned and water-tanned leather depends on balancing toughness and comfort for pet products.

Table of Comparison

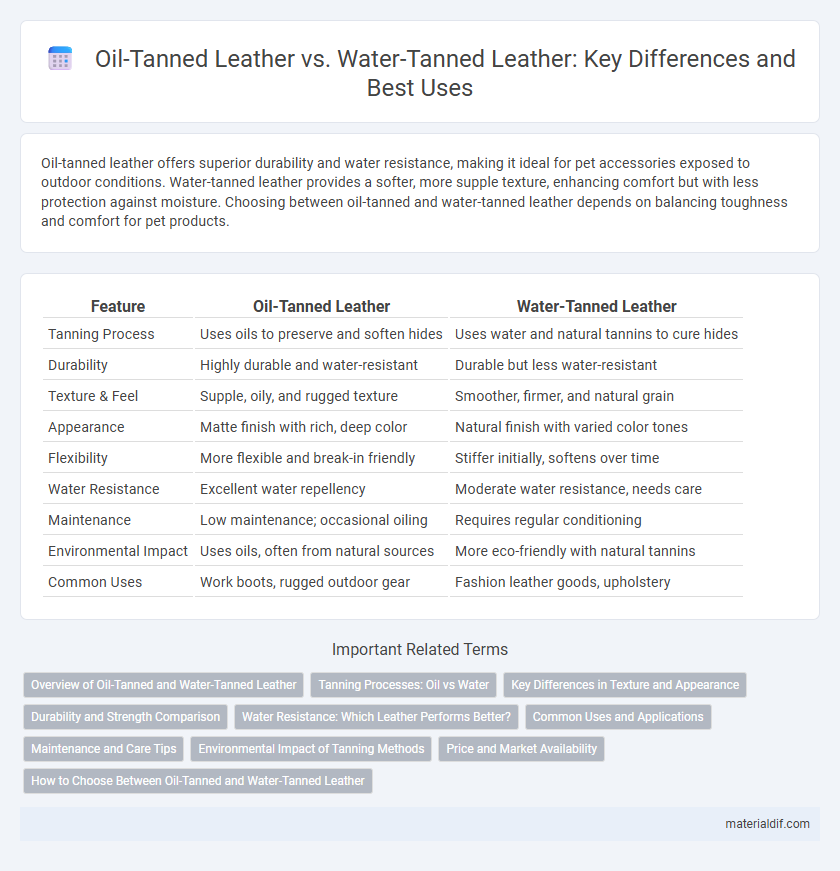

| Feature | Oil-Tanned Leather | Water-Tanned Leather |

|---|---|---|

| Tanning Process | Uses oils to preserve and soften hides | Uses water and natural tannins to cure hides |

| Durability | Highly durable and water-resistant | Durable but less water-resistant |

| Texture & Feel | Supple, oily, and rugged texture | Smoother, firmer, and natural grain |

| Appearance | Matte finish with rich, deep color | Natural finish with varied color tones |

| Flexibility | More flexible and break-in friendly | Stiffer initially, softens over time |

| Water Resistance | Excellent water repellency | Moderate water resistance, needs care |

| Maintenance | Low maintenance; occasional oiling | Requires regular conditioning |

| Environmental Impact | Uses oils, often from natural sources | More eco-friendly with natural tannins |

| Common Uses | Work boots, rugged outdoor gear | Fashion leather goods, upholstery |

Overview of Oil-Tanned and Water-Tanned Leather

Oil-tanned leather is treated with natural oils and waxes, resulting in a resilient, water-resistant surface that retains flexibility and develops a rich patina over time. Water-tanned leather undergoes a traditional vegetable tanning process using tannins found in tree bark and plants, producing a sturdy, breathable leather with a firm texture and enhanced color depth. Both tanning methods impact leather's durability, appearance, and maintenance, with oil-tanned leather favored for rugged outdoor use and water-tanned leather prized for craftsmanship and heritage aesthetics.

Tanning Processes: Oil vs Water

Oil-tanned leather undergoes a tanning process using oils and waxes, which penetrate deep into the fibers, resulting in leather that is highly water-resistant, flexible, and durable. Water-tanned leather, also known as vegetable-tanned leather, is treated with water-based tannins derived from plant materials, producing a stiffer, more breathable hide that develops a natural patina over time. The key difference in tanning processes lies in oil tanning's hydrophobic treatment for enhanced moisture protection versus water tanning's eco-friendly, traditional method emphasizing firmness and aging characteristics.

Key Differences in Texture and Appearance

Oil-tanned leather features a supple texture and a rich, dark finish due to the infusion of natural oils during the tanning process, giving it a glossy and water-resistant surface. Water-tanned leather, on the other hand, has a lighter, more matte appearance with a firmer texture, reflecting fewer oils and emphasizing natural grain patterns. Key differences in appearance include oil-tanned leather's enhanced durability and sheen compared to the more natural, organic look of water-tanned leather.

Durability and Strength Comparison

Oil-tanned leather offers exceptional durability and water resistance due to the infusion of oils during the tanning process, making it highly resistant to cracking and wear over time. Water-tanned leather, while more flexible and breathable, generally lacks the same level of robust strength and is more prone to damage from prolonged exposure to moisture. For applications requiring strong, long-lasting materials, oil-tanned leather is typically preferred over water-tanned variants.

Water Resistance: Which Leather Performs Better?

Oil-tanned leather offers superior water resistance due to its infusion with natural oils that create a durable, hydrophobic barrier, making it ideal for wet environments. Water-tanned leather, treated primarily with water-based tanning agents, is more susceptible to moisture absorption and tends to require additional waterproofing treatments. For applications demanding maximum water resistance and longevity under damp conditions, oil-tanned leather consistently outperforms water-tanned leather.

Common Uses and Applications

Oil-tanned leather is commonly used in heavy-duty applications such as work boots, saddles, and motorcycle gear due to its durability, water resistance, and ability to develop a rich patina over time. Water-tanned leather is often favored for fine leather goods like garments, gloves, and upholstery because of its softness, flexibility, and ability to hold detailed embossing or dyeing. Both types of leather find distinct roles in fashion and utility markets, tailored to specific functional and aesthetic requirements.

Maintenance and Care Tips

Oil-tanned leather requires regular application of leather conditioners to maintain its suppleness and prevent drying or cracking, while avoiding excessive water exposure to preserve its oily finish. Water-tanned leather benefits from gentle cleaning with a damp cloth and should be conditioned with natural oils to enhance flexibility and water resistance. Both types should be stored in a cool, dry place away from direct sunlight to prevent fading and deterioration.

Environmental Impact of Tanning Methods

Oil-tanned leather involves using oils and waxes to treat the hide, resulting in a more water-resistant and durable material with lower chemical waste compared to traditional tanning. Water-tanned leather relies on water-based solutions, often utilizing chromium or vegetable tannins, which can lead to higher water consumption and potential pollutant runoff if not managed properly. Environmentally, oil tanning generally produces less harmful effluents and lower energy usage, making it a more sustainable option compared to water-tanned processes that may contribute to aquatic pollution and increased resource use.

Price and Market Availability

Oil-tanned leather typically commands a higher price due to its complex processing and enhanced durability, making it less common in mainstream markets but favored in premium leather goods. Water-tanned leather is more widely available and affordable, appealing to budget-conscious consumers and mass-market manufacturers. Both types cater to different market segments, with oil-tanned leather positioned as a luxury option and water-tanned leather serving more accessible product lines.

How to Choose Between Oil-Tanned and Water-Tanned Leather

Choosing between oil-tanned and water-tanned leather depends on the desired durability and appearance; oil-tanned leather offers superior water resistance and a rich, supple finish ideal for rugged use, while water-tanned leather provides a softer, more natural texture suited for refined, delicate products. Consider the intended application, exposure to moisture, and maintenance preferences to determine which tanning process aligns with your needs. Understanding these characteristics ensures selection of the appropriate leather type for longevity and aesthetic appeal.

Oil-Tanned Leather vs Water-Tanned Leather Infographic

materialdif.com

materialdif.com