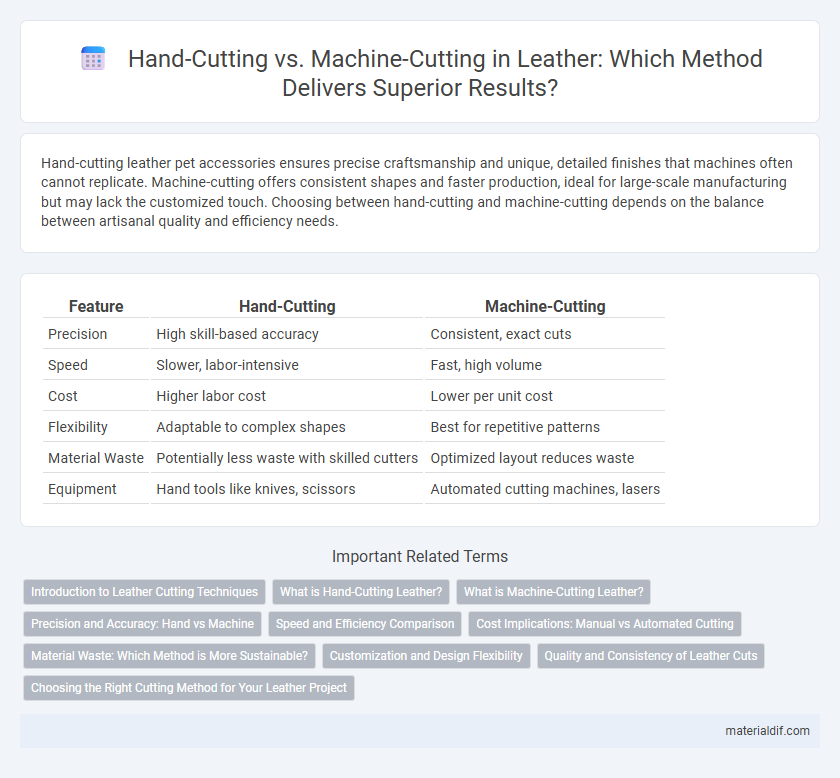

Hand-cutting leather pet accessories ensures precise craftsmanship and unique, detailed finishes that machines often cannot replicate. Machine-cutting offers consistent shapes and faster production, ideal for large-scale manufacturing but may lack the customized touch. Choosing between hand-cutting and machine-cutting depends on the balance between artisanal quality and efficiency needs.

Table of Comparison

| Feature | Hand-Cutting | Machine-Cutting |

|---|---|---|

| Precision | High skill-based accuracy | Consistent, exact cuts |

| Speed | Slower, labor-intensive | Fast, high volume |

| Cost | Higher labor cost | Lower per unit cost |

| Flexibility | Adaptable to complex shapes | Best for repetitive patterns |

| Material Waste | Potentially less waste with skilled cutters | Optimized layout reduces waste |

| Equipment | Hand tools like knives, scissors | Automated cutting machines, lasers |

Introduction to Leather Cutting Techniques

Hand-cutting leather involves skilled artisans using precision knives to create intricate designs and custom shapes, ensuring unique, detailed craftsmanship. Machine-cutting employs automated tools like die-cutters or laser cutters for high-speed, uniform, and scalable production, ideal for mass manufacturing. Both techniques impact leather's texture and edge finish, influencing the final product's quality and appearance.

What is Hand-Cutting Leather?

Hand-cutting leather involves using precision tools such as sharp knives or rotary cutters to manually slice leather pieces according to specific patterns, ensuring high customization and attention to detail. This traditional technique allows artisans to maintain control over the thickness, shape, and grain alignment, resulting in superior quality and uniqueness in each piece. Unlike machine-cutting, hand-cutting minimizes waste and enhances the tactile authenticity of the leather products.

What is Machine-Cutting Leather?

Machine-cutting leather involves using automated tools such as die-cutters, laser cutters, or CNC machines to precisely shape leather pieces. This method increases production speed and consistency, ensuring uniform cuts ideal for mass manufacturing. Machine-cutting reduces material waste and minimizes human error compared to hand-cutting techniques.

Precision and Accuracy: Hand vs Machine

Hand-cutting leather offers artisanal precision, allowing skilled craftsmen to tailor each piece with unique accuracy that adapts to subtle material variations. Machine-cutting leather ensures consistent accuracy and uniformity in shape and size, optimizing efficiency for large-scale production. Precision in hand-cutwork excels in bespoke projects, while machine precision dominates repetitive, high-volume manufacturing.

Speed and Efficiency Comparison

Hand-cutting leather offers precision and detail but is significantly slower compared to machine-cutting, which can process multiple pieces rapidly with consistent accuracy. Machine-cutting enhances efficiency by reducing labor time and minimizing material waste through automated, high-speed operation. For large-scale production, machine-cutting is preferred due to its ability to maintain uniform quality while maximizing output speed.

Cost Implications: Manual vs Automated Cutting

Hand-cutting leather requires skilled labor, resulting in higher costs due to increased time and precision needed for each piece. Automated machine-cutting significantly reduces production time and labor expenses, enabling more efficient large-scale manufacturing. However, machine-cutting may involve upfront investment in equipment and maintenance, balancing long-term savings against initial costs.

Material Waste: Which Method is More Sustainable?

Hand-cutting leather minimizes material waste by allowing artisans to carefully position patterns to maximize yield from each hide, resulting in less offcut scrap compared to machine-cutting. Machine-cutting, while faster and more consistent, often produces larger quantities of uniform scraps due to less precise pattern placement and the need for repeated dies, leading to increased material waste. Prioritizing hand-cutting in leather production supports sustainability by optimizing resource use and reducing environmental impact associated with leather waste disposal.

Customization and Design Flexibility

Hand-cutting leather allows for unparalleled customization and intricate design flexibility, enabling artisans to create unique patterns and shapes tailored to specific preferences. Machine-cutting offers precision and consistency, but often lacks the nuanced detailing achievable through manual techniques. This balance between craftsmanship and efficiency defines the choice for bespoke leather products versus mass-produced items.

Quality and Consistency of Leather Cuts

Hand-cutting leather offers superior precision and attention to detail, resulting in unique, high-quality cuts tailored to specific design needs. Machine-cutting ensures consistent, uniform leather pieces with minimal variation, optimizing efficiency and reducing material waste. Both methods impact the final product's quality, but hand-cutting is preferred for artisanal craftsmanship, while machine-cutting suits mass production demands.

Choosing the Right Cutting Method for Your Leather Project

Hand-cutting leather offers precise control and customization ideal for intricate designs and small-scale projects, enhancing craftsmanship quality. Machine-cutting provides consistent, rapid cuts suitable for mass production and uniform pieces, improving efficiency and reducing material waste. Evaluating project complexity, volume, and desired finish helps determine the optimal cutting method for superior results in leatherwork.

Hand-Cutting vs Machine-Cutting Infographic

materialdif.com

materialdif.com