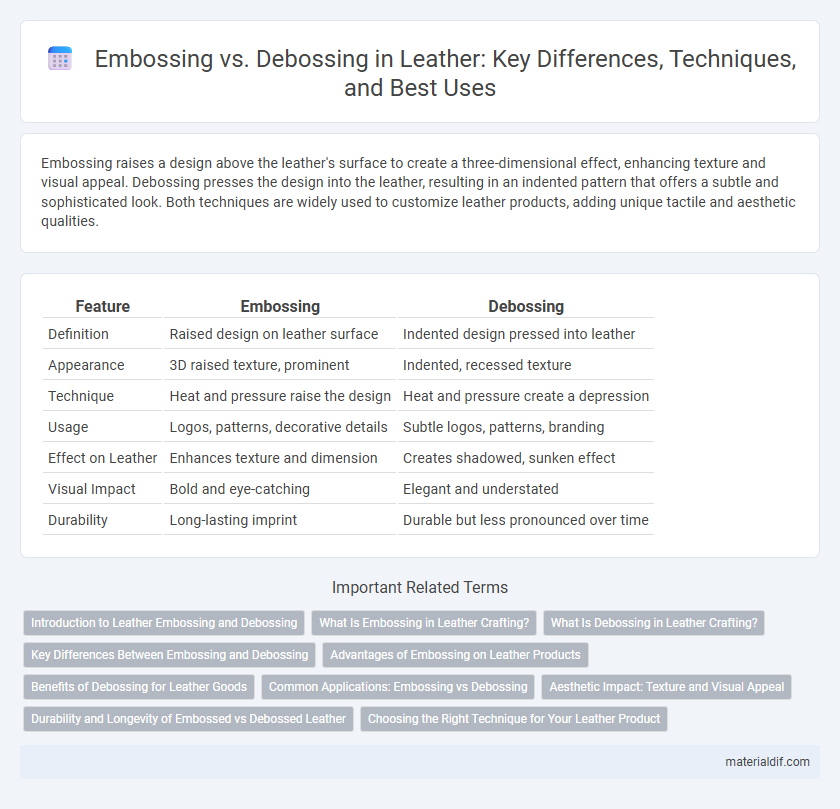

Embossing raises a design above the leather's surface to create a three-dimensional effect, enhancing texture and visual appeal. Debossing presses the design into the leather, resulting in an indented pattern that offers a subtle and sophisticated look. Both techniques are widely used to customize leather products, adding unique tactile and aesthetic qualities.

Table of Comparison

| Feature | Embossing | Debossing |

|---|---|---|

| Definition | Raised design on leather surface | Indented design pressed into leather |

| Appearance | 3D raised texture, prominent | Indented, recessed texture |

| Technique | Heat and pressure raise the design | Heat and pressure create a depression |

| Usage | Logos, patterns, decorative details | Subtle logos, patterns, branding |

| Effect on Leather | Enhances texture and dimension | Creates shadowed, sunken effect |

| Visual Impact | Bold and eye-catching | Elegant and understated |

| Durability | Long-lasting imprint | Durable but less pronounced over time |

Introduction to Leather Embossing and Debossing

Leather embossing creates raised patterns by pressing designs into the surface using heat and pressure, enhancing texture and visual appeal. Debossing, conversely, produces recessed imprints that sink below the leather's surface for a subtle, elegant effect. Both techniques utilize metal dies and precise temperature control to ensure durable, high-quality finishes on leather products.

What Is Embossing in Leather Crafting?

Embossing in leather crafting refers to the process of creating raised designs or patterns on the leather surface by applying heat and pressure with engraved dies. This technique enhances texture and visual appeal, making the leather more tactile and unique. Embossed leather is commonly used in luxury goods, accessories, and custom designs to add intricate detailing without compromising durability.

What Is Debossing in Leather Crafting?

Debossing in leather crafting is a technique that creates recessed designs by pressing an image or pattern into the leather surface, resulting in an indented effect. This process uses specialized tools or heat to imprint logos, text, or decorative elements, enhancing texture and visual depth. Debossing contrasts with embossing, which raises the design above the leather surface, making it a preferred method for subtle, elegant customization.

Key Differences Between Embossing and Debossing

Embossing raises a leather surface to create a three-dimensional design, enhancing texture and visual appeal, while debossing presses the design into the leather, producing an indented effect. Embossing typically adds depth and prominence to logos or patterns, whereas debossing offers a subtle, recessed look often used for branding or sophisticated detailing. Both techniques rely on heat and pressure but differ in their impact on leather's tactile and aesthetic qualities.

Advantages of Embossing on Leather Products

Embossing on leather products creates raised patterns that enhance tactile appeal and visual depth, making designs more prominent and luxurious. This technique improves durability by protecting the elevated areas from wear and tear, maintaining the leather's aesthetic over time. Embossed leather also offers greater design versatility, allowing for intricate, detailed textures that enhance brand identity and product uniqueness.

Benefits of Debossing for Leather Goods

Debossing enhances leather goods by creating recessed designs that add depth and texture without compromising the material's surface integrity, resulting in a subtle and elegant finish. This technique preserves the leather's durability while providing a sophisticated branding or decorative effect that ages gracefully over time. Debossing also allows for precise detailing, making it ideal for personalized items and luxury leather products seeking understated customization.

Common Applications: Embossing vs Debossing

Embossing on leather is commonly used in luxury handbags, wallets, and belts to create raised patterns or logos that enhance texture and brand recognition. Debossing is frequently applied in leather book covers, journals, and premium packaging to produce recessed designs that offer a subtle, elegant finish. Both techniques are popular in personalized leather goods, with embossing emphasizing bold, tactile elements and debossing highlighting refined, understated impressions.

Aesthetic Impact: Texture and Visual Appeal

Embossing on leather creates a raised texture that enhances visual depth and tactile interest, giving designs a bold and prominent appearance. Debossing, meanwhile, produces recessed patterns that offer a subtle, refined look with a smooth surface feel, often emphasizing elegance and sophistication. Both techniques significantly influence leather's aesthetic appeal by altering light reflection and texture, which can complement various styles and applications.

Durability and Longevity of Embossed vs Debossed Leather

Embossed leather features raised patterns created by pressing materials into the leather surface, which enhances its durability by providing a tougher exterior layer resistant to wear and scratches. Debossed leather, with its recessed designs, can be more susceptible to dirt accumulation and wear over time, potentially reducing its longevity compared to embossed finishes. Both techniques preserve leather quality, but embossed leather generally offers better resistance to daily abrasion and maintains its aesthetic appeal longer.

Choosing the Right Technique for Your Leather Product

Embossing raises the leather surface creating a textured, three-dimensional design, while debossing presses an image or pattern into the leather for a recessed effect, both enhancing the product's aesthetic appeal. Selecting the right technique depends on the desired visual impact, with embossing adding boldness and depth and debossing offering subtle refinement and sophistication. Factors such as leather type, product function, and brand identity play crucial roles in determining the optimal method for achieving durable, high-quality results.

Embossing vs Debossing Infographic

materialdif.com

materialdif.com