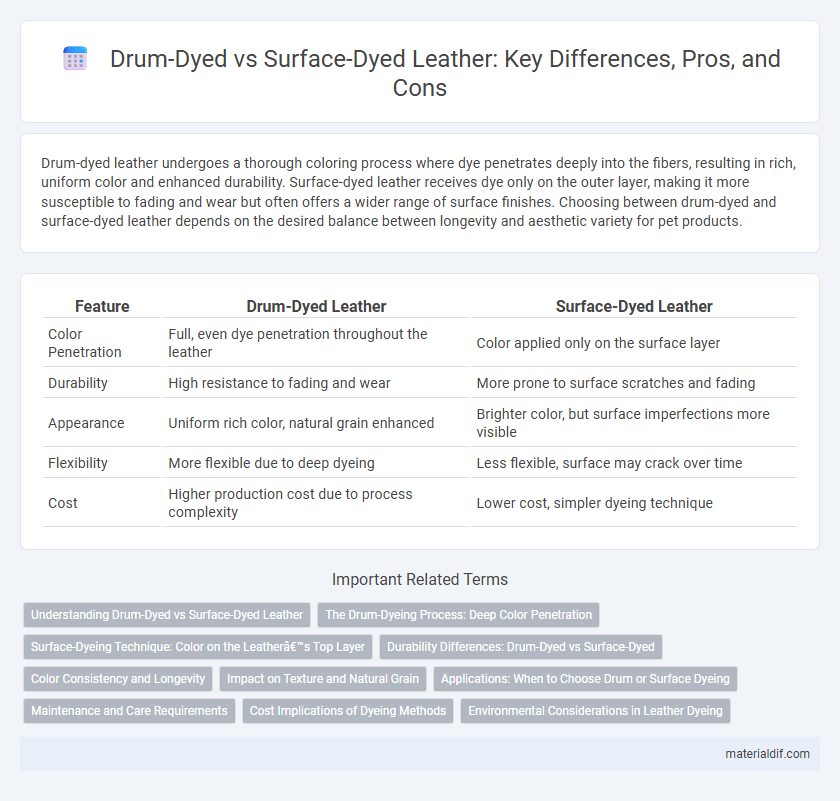

Drum-dyed leather undergoes a thorough coloring process where dye penetrates deeply into the fibers, resulting in rich, uniform color and enhanced durability. Surface-dyed leather receives dye only on the outer layer, making it more susceptible to fading and wear but often offers a wider range of surface finishes. Choosing between drum-dyed and surface-dyed leather depends on the desired balance between longevity and aesthetic variety for pet products.

Table of Comparison

| Feature | Drum-Dyed Leather | Surface-Dyed Leather |

|---|---|---|

| Color Penetration | Full, even dye penetration throughout the leather | Color applied only on the surface layer |

| Durability | High resistance to fading and wear | More prone to surface scratches and fading |

| Appearance | Uniform rich color, natural grain enhanced | Brighter color, but surface imperfections more visible |

| Flexibility | More flexible due to deep dyeing | Less flexible, surface may crack over time |

| Cost | Higher production cost due to process complexity | Lower cost, simpler dyeing technique |

Understanding Drum-Dyed vs Surface-Dyed Leather

Drum-dyed leather undergoes a process where dye penetrates through the entire hide, ensuring deeper color saturation and enhanced durability against wear and fading. Surface-dyed leather, on the other hand, receives dye applied only to the exterior, creating vibrant finishes but more susceptible to scratches and color loss over time. Choosing between drum-dyed and surface-dyed leather depends on desired longevity, color intensity, and the specific application in products like furniture, automotive interiors, or fashion accessories.

The Drum-Dyeing Process: Deep Color Penetration

The drum-dyeing process ensures deep color penetration by immersing leather hides in large rotating drums filled with dye, allowing the color to saturate thoroughly through the material's fibers. This technique enhances durability and colorfastness compared to surface-dyed leather, which only has dye applied on the surface. Drum-dyed leather is preferred for products requiring rich, long-lasting hues such as luxury handbags and upholstery.

Surface-Dyeing Technique: Color on the Leather’s Top Layer

Surface-dyeing technique applies color directly onto the leather's top layer, enhancing design precision and allowing for vibrant, customizable finishes. Unlike drum-dyed leather, which penetrates color throughout the material, surface-dyed leather highlights the grain and texture, offering a distinct aesthetic often preferred for high-fashion and decorative applications. This method typically results in a leather surface that ages with unique patinas, reflecting wear while maintaining its original color intensity.

Durability Differences: Drum-Dyed vs Surface-Dyed

Drum-dyed leather undergoes a thorough dyeing process where the dye penetrates deep into the fibers, resulting in superior durability and resistance to fading, cracking, and wear over time. Surface-dyed leather receives color applied only on the outer layer, making it more susceptible to scratches, fading, and damage from moisture exposure. Consequently, drum-dyed leather maintains its appearance and structural integrity significantly longer than surface-dyed leather in high-use environments.

Color Consistency and Longevity

Drum-dyed leather achieves superior color consistency by immersing hides in dye baths, allowing pigments to penetrate deeply and evenly, which enhances uniformity across the entire hide. Surface-dyed leather applies color only on the outer layer, making it more susceptible to fading and wear over time, resulting in less longevity compared to drum-dyed options. The deeper pigment infusion in drum-dyed leather provides enhanced durability, retaining vibrant color even after repeated use and exposure to sunlight.

Impact on Texture and Natural Grain

Drum-dyed leather undergoes a deep coloration process that preserves and enhances the natural grain and texture, resulting in a rich, uniform color while maintaining the leather's original softness and flexibility. Surface-dyed leather, on the other hand, receives color only on the outer layer, which can mask imperfections but often leads to a stiffer texture and less pronounced natural grain patterns. The choice between drum-dyed and surface-dyed methods directly affects the tactile quality and visual depth, with drum-dyeing offering a more authentic, textured finish that highlights natural leather characteristics.

Applications: When to Choose Drum or Surface Dyeing

Drum-dyed leather is ideal for applications requiring deep color penetration and enhanced durability, such as high-quality footwear, automotive upholstery, and heavy-use furniture, where resistance to wear and consistent coloring are critical. Surface-dyed leather suits products emphasizing aesthetic appeal with varied color effects and textures, including fashion accessories, decorative items, and lighter-use furniture, where color vibrancy and finish customization are prioritized. Selecting between drum and surface dyeing depends on balancing long-lasting performance needs against design flexibility and visual impact.

Maintenance and Care Requirements

Drum-dyed leather offers superior color penetration, reducing the risk of fading and making it easier to maintain with regular cleaning and conditioning. Surface-dyed leather requires more frequent attention as its color resides only on the outer layer, making it more susceptible to scratches and discoloration. Proper care involves using pH-balanced leather conditioners and avoiding harsh chemicals to extend the leather's appearance and durability for both types.

Cost Implications of Dyeing Methods

Drum-dyed leather involves immersing hides in large vats, allowing dye to penetrate deeply, resulting in higher durability but increased processing costs due to extended dyeing times and specialized equipment. Surface-dyed leather undergoes a quicker, less expensive method where dye is applied only to the outer layer, which lowers production expenses but compromises long-term wear resistance. Manufacturers typically face a cost-benefit analysis balancing drum-dyeing's premium price against surface-dyeing's budget-friendly but less durable finish.

Environmental Considerations in Leather Dyeing

Drum-dyed leather involves immersing hides in a rotating drum with dye, allowing deep penetration and uniform color, which reduces the need for excess dye and water, minimizing environmental impact. Surface-dyed leather applies color only to the outer layer, often requiring more chemicals and repeated treatments, resulting in higher emissions and waste. Choosing drum-dyed methods supports sustainable leather production by conserving resources and reducing pollutant discharge.

Drum-dyed vs Surface-dyed Infographic

materialdif.com

materialdif.com