Granite quarrying involves extracting natural stone directly from the earth, which requires heavy machinery and results in significant environmental impact, including habitat disruption and high energy use. Granite recycling, on the other hand, repurposes waste granite from demolished buildings or manufacturing scraps, reducing landfill waste and conserving natural resources. Emphasizing recycled granite promotes sustainable practices by minimizing the need for quarrying while maintaining the material's durability and aesthetic appeal.

Table of Comparison

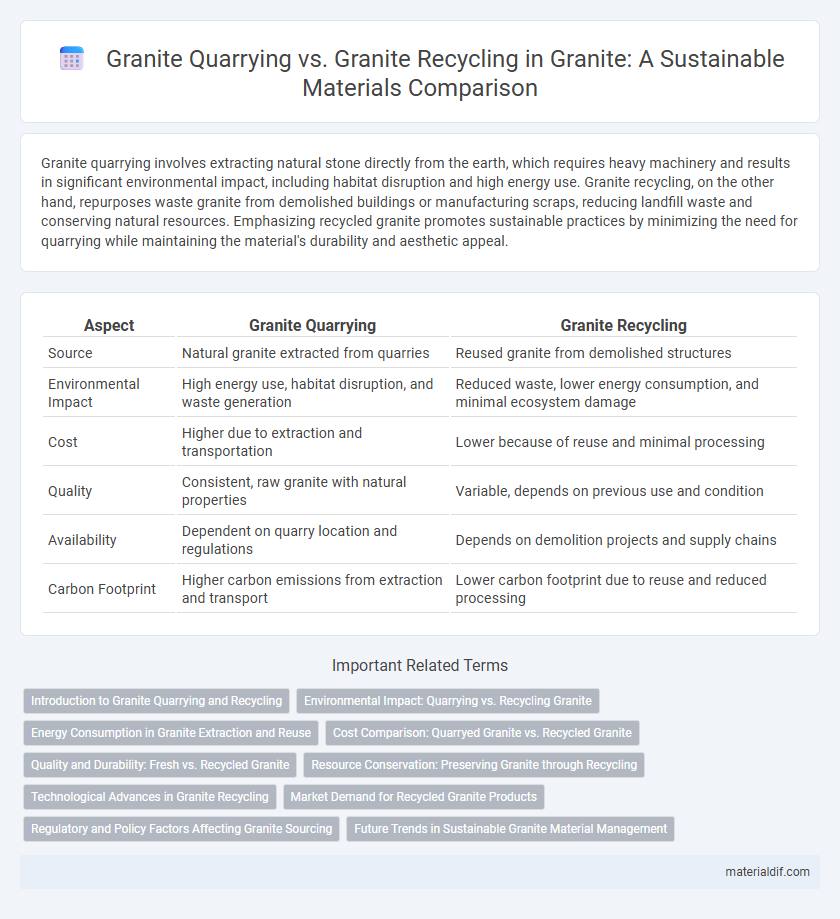

| Aspect | Granite Quarrying | Granite Recycling |

|---|---|---|

| Source | Natural granite extracted from quarries | Reused granite from demolished structures |

| Environmental Impact | High energy use, habitat disruption, and waste generation | Reduced waste, lower energy consumption, and minimal ecosystem damage |

| Cost | Higher due to extraction and transportation | Lower because of reuse and minimal processing |

| Quality | Consistent, raw granite with natural properties | Variable, depends on previous use and condition |

| Availability | Dependent on quarry location and regulations | Depends on demolition projects and supply chains |

| Carbon Footprint | Higher carbon emissions from extraction and transport | Lower carbon footprint due to reuse and reduced processing |

Introduction to Granite Quarrying and Recycling

Granite quarrying involves extracting large blocks of natural granite from open-pit mines, a process requiring heavy machinery and significant energy consumption. Granite recycling repurposes waste granite from demolition or production offcuts, reducing environmental impact and conserving natural resources. Both methods contribute to the granite supply chain, but recycling offers a sustainable alternative by minimizing quarrying demands and associated ecological disruption.

Environmental Impact: Quarrying vs. Recycling Granite

Granite quarrying significantly alters landscapes, leading to habitat destruction and increased carbon emissions from heavy machinery and transportation. Recycling granite reduces the demand for new quarrying, minimizing waste sent to landfills and conserving natural resources. Utilizing recycled granite supports sustainable construction practices by lowering energy consumption and decreasing environmental degradation.

Energy Consumption in Granite Extraction and Reuse

Granite quarrying involves significant energy consumption due to heavy machinery, blasting, and transportation required for extraction and processing. In contrast, granite recycling drastically reduces energy usage by reusing existing materials, minimizing the need for intense extraction activities. This shift lowers carbon emissions and conserves natural resources, making recycling a more sustainable option in granite utilization.

Cost Comparison: Quarryed Granite vs. Recycled Granite

Quarryed granite involves high extraction and transportation expenses due to heavy machinery and labor-intensive processes, resulting in higher overall costs. Recycled granite significantly reduces costs by repurposing existing materials, minimizing raw material expenses and energy consumption. When comparing cost efficiency, recycled granite offers a more economical alternative without compromising quality, making it favorable for budget-conscious construction projects.

Quality and Durability: Fresh vs. Recycled Granite

Fresh granite from quarries maintains superior quality and durability due to its unaltered mineral structure and density, ensuring long-lasting performance in construction and design. Recycled granite, while environmentally beneficial, may exhibit slight variations in strength and consistency from previous use, potentially affecting its uniformity and lifespan. Choosing between quarrying and recycling depends on balancing the need for premium material properties with sustainability goals.

Resource Conservation: Preserving Granite through Recycling

Granite recycling significantly conserves natural resources by reducing the demand for fresh quarrying, which depletes finite granite deposits. Quarrying often leads to habitat disruption and extensive energy use, whereas recycling granite salvages usable materials from demolition waste, minimizing environmental impact. This sustainable approach preserves granite reserves, supporting long-term availability and reducing the ecological footprint of granite production.

Technological Advances in Granite Recycling

Technological advances in granite recycling have transformed waste granite into high-quality aggregates and decorative materials, reducing the demand for quarrying and minimizing environmental impact. Innovations such as advanced crushing techniques and automated sorting systems enhance material recovery efficiency and product consistency. These developments promote sustainable practices by lowering energy consumption and preserving natural granite reserves compared to traditional quarrying methods.

Market Demand for Recycled Granite Products

Market demand for recycled granite products is steadily increasing as sustainability efforts influence construction and design industries, reducing reliance on new quarrying. Recycled granite offers cost-effective, eco-friendly alternatives that conserve natural resources and minimize quarry waste, appealing to environmentally conscious consumers. This shift drives growth in the recycled granite market, encouraging innovation in processing techniques and expanding applications in landscaping, flooring, and architectural features.

Regulatory and Policy Factors Affecting Granite Sourcing

Granite quarrying is heavily influenced by stringent environmental regulations and land use policies that govern extraction permits, rehabilitation requirements, and emissions control, often making the permitting process lengthy and costly. In contrast, granite recycling benefits from fewer regulatory barriers and aligns with sustainable sourcing policies promoting waste reduction and circular economy practices. Governments increasingly incentivize recycled granite use through tax breaks and certification programs to meet environmental targets and reduce the carbon footprint associated with traditional quarrying.

Future Trends in Sustainable Granite Material Management

Granite quarrying faces increasing environmental challenges, driving the demand for sustainable alternatives such as granite recycling, which reduces waste and conserves natural resources. Advances in recycling technologies enable the recovery of high-quality granite aggregates and slabs, promoting circular economy practices in the construction and design industries. Future trends in sustainable granite material management emphasize integrated supply chains that balance ecological impact, cost efficiency, and material durability.

granite quarrying vs granite recycling Infographic

materialdif.com

materialdif.com