Hard gold offers superior durability and resistance to scratches, making it ideal for fine jewelry and items subject to daily wear. Soft gold, being more malleable, allows for intricate designs and detailed craftsmanship but is prone to bending and scratches over time. Choosing between hard gold and soft gold depends on the balance needed between longevity and artistic detail in gold pet accessories.

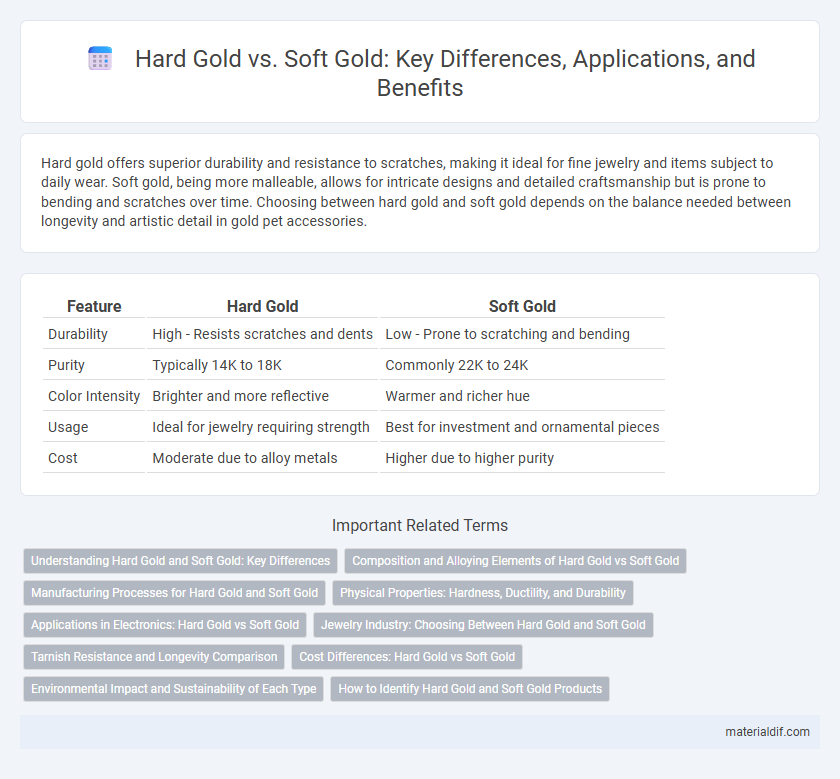

Table of Comparison

| Feature | Hard Gold | Soft Gold |

|---|---|---|

| Durability | High - Resists scratches and dents | Low - Prone to scratching and bending |

| Purity | Typically 14K to 18K | Commonly 22K to 24K |

| Color Intensity | Brighter and more reflective | Warmer and richer hue |

| Usage | Ideal for jewelry requiring strength | Best for investment and ornamental pieces |

| Cost | Moderate due to alloy metals | Higher due to higher purity |

Understanding Hard Gold and Soft Gold: Key Differences

Hard gold, often alloyed with metals like copper, nickel, or palladium, is prized for its enhanced durability and resistance to scratching, making it ideal for jewelry and industrial uses. Soft gold, typically 24-karat and nearly pure, is more malleable and prone to deformation, favored for investment and certain electronics where high conductivity is essential. The primary difference lies in hardness and durability, influencing their applications based on the gold's composition and karat value.

Composition and Alloying Elements of Hard Gold vs Soft Gold

Hard gold typically contains a mixture of gold with alloys such as cobalt, nickel, or iron, which increase its hardness and durability, making it ideal for applications requiring wear resistance. Soft gold is nearly pure gold with minimal alloying elements, usually over 99% gold, providing a more malleable and ductile material suited for delicate jewelry and fine detail work. The differing alloy compositions directly affect mechanical properties, with hard gold's added metals enhancing scratch resistance while soft gold retains its traditional luster and ease of shaping.

Manufacturing Processes for Hard Gold and Soft Gold

Hard gold, used in electronic connectors and circuit boards, is deposited through electroplating with nickel or cobalt underlayers to enhance durability and wear resistance. Soft gold, characterized by higher purity and malleability, is typically applied by vapor deposition or electroforming for decorative and jewelry applications. Manufacturing processes for hard gold prioritize hardness and corrosion resistance, while those for soft gold focus on achieving a smooth, pure, and aesthetically pleasing finish.

Physical Properties: Hardness, Ductility, and Durability

Hard gold, typically alloyed with elements like nickel or cobalt, exhibits greater hardness and improved durability compared to soft gold, making it more resistant to scratches and wear. Soft gold, composed of nearly pure gold (24 karats), is highly ductile and malleable but lacks the strength needed for robust applications due to its lower hardness. The enhanced hardness of hard gold alloys ensures superior longevity in jewelry and electronic components, while soft gold's exceptional ductility enables intricate shaping and fine detailing.

Applications in Electronics: Hard Gold vs Soft Gold

Hard gold, composed primarily of gold alloyed with small amounts of cobalt or nickel, provides superior durability and corrosion resistance, making it ideal for electronic connectors, contacts, and printed circuit boards that endure frequent mating cycles. Soft gold, nearly pure gold (24 karats), offers excellent conductivity and solderability but wears more quickly, thus it is preferred for applications like bonding wires and thin plating layers where minimal mechanical wear occurs. The selection between hard gold and soft gold hinges on balancing the need for electrical performance with mechanical robustness in various electronic components.

Jewelry Industry: Choosing Between Hard Gold and Soft Gold

Hard gold, known for its durability and resistance to scratches, is preferred in the jewelry industry for pieces subjected to frequent wear, such as rings and bracelets. Soft gold, characterized by higher purity and malleability, is ideal for intricate designs and delicate craftsmanship but requires careful handling. Jewelers balance hardness and purity to meet aesthetic demands while ensuring longevity and comfort for the wearer.

Tarnish Resistance and Longevity Comparison

Hard gold alloys contain a higher percentage of copper and other metals, enhancing their tarnish resistance and durability compared to soft gold, which is purer and more prone to scratching and discoloration. Tarnish resistance in hard gold allows jewelry and electronic contacts to maintain their shine and conductivity over extended periods. Soft gold's higher malleability offers ease of shaping but compromises longevity, as it wears down faster and develops surface imperfections more readily.

Cost Differences: Hard Gold vs Soft Gold

Hard gold, typically alloyed with metals like nickel or copper, exhibits greater durability and resistance to wear, leading to higher production costs compared to soft gold, which is purer and more malleable. The increased hardness in hard gold requires more complex manufacturing processes, thus raising its price in jewelry and industrial applications. Soft gold, valued for its purity, is less expensive to produce but may incur higher maintenance costs due to its susceptibility to scratches and deformation.

Environmental Impact and Sustainability of Each Type

Hard gold plating uses a higher percentage of nickel and other alloys, increasing its durability but also its environmental footprint due to toxic metal residues and intensive energy consumption during processing. Soft gold, being purer and less alloyed, offers easier recyclability and lower ecological impact, promoting sustainable practices in jewelry and electronics production. Evaluating lifecycle emissions, soft gold demonstrates superior sustainability potential by minimizing hazardous waste and supporting circular economy principles.

How to Identify Hard Gold and Soft Gold Products

Hard gold typically contains a higher percentage of copper alloy, making it more durable and suitable for jewelry that withstands daily wear. Soft gold products have a higher purity level, usually 18K or 24K, resulting in a softer, more malleable material prone to scratches and dents. Identification involves testing for karat marks, assessing weight and color density, and conducting a scratch or bend test to distinguish the hardness of the gold alloy.

Hard Gold vs Soft Gold Infographic

materialdif.com

materialdif.com