Nylon is a synthetic fabric known for its durability, resistance to abrasion, and moisture-wicking properties, making it ideal for activewear and outdoor gear. Spandex, also a synthetic fiber, offers exceptional elasticity and stretch, providing enhanced comfort and flexibility in garments like sportswear and shapewear. Combining nylon with spandex creates a fabric blend that balances strength with stretchability, resulting in clothing that fits well and retains its shape during movement.

Table of Comparison

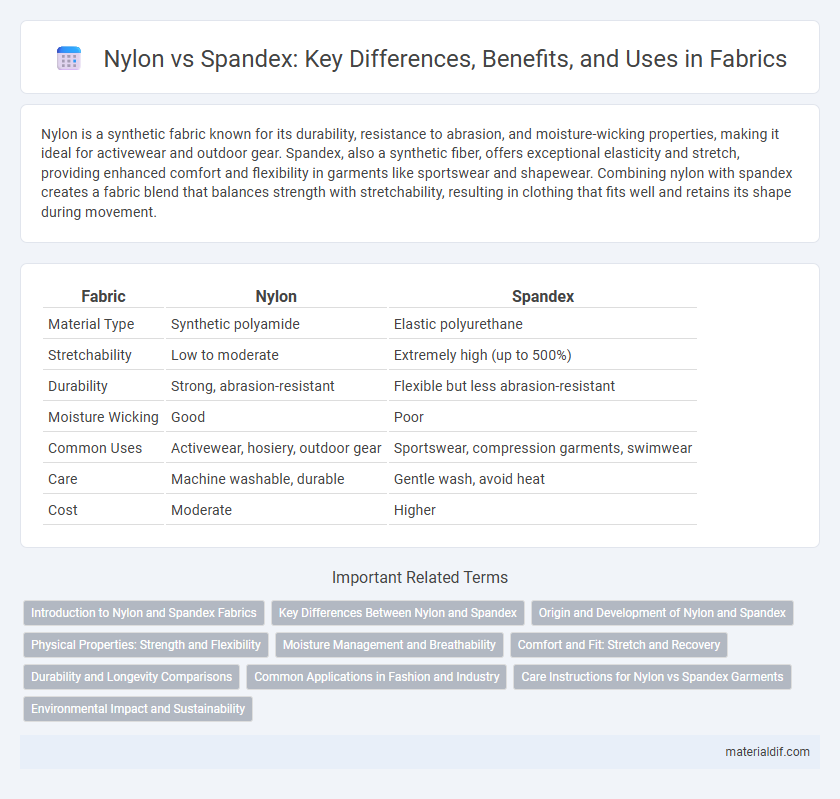

| Fabric | Nylon | Spandex |

|---|---|---|

| Material Type | Synthetic polyamide | Elastic polyurethane |

| Stretchability | Low to moderate | Extremely high (up to 500%) |

| Durability | Strong, abrasion-resistant | Flexible but less abrasion-resistant |

| Moisture Wicking | Good | Poor |

| Common Uses | Activewear, hosiery, outdoor gear | Sportswear, compression garments, swimwear |

| Care | Machine washable, durable | Gentle wash, avoid heat |

| Cost | Moderate | Higher |

Introduction to Nylon and Spandex Fabrics

Nylon is a strong, lightweight synthetic fiber known for its durability, elasticity, and resistance to abrasion and chemicals, making it ideal for activewear and outerwear. Spandex, also called elastane or Lycra, is highly stretchable, providing exceptional flexibility and shape retention in garments such as sportswear and swimwear. Both fibers are often blended to enhance comfort, fit, and performance in modern textile applications.

Key Differences Between Nylon and Spandex

Nylon is a synthetic fiber known for its strength, durability, and resistance to abrasion, making it ideal for heavy-duty fabrics and outerwear. Spandex, on the other hand, offers exceptional elasticity and stretch, providing superior flexibility and comfort in activewear and form-fitting garments. Unlike nylon, which maintains shape and resists wrinkles, spandex excels in recovery and flexibility but is often blended with other fibers to enhance stretchability.

Origin and Development of Nylon and Spandex

Nylon, developed by Wallace Carothers at DuPont in 1935, marked the first commercially successful synthetic fiber, revolutionizing the textile industry with its strength and elasticity derived from polyamide polymers. Spandex, invented in 1958 by chemist Joseph Shivers at DuPont, introduced exceptional stretchability and recovery properties through its polyurethane-based structure, enhancing comfort and fit in fabrics. Both fibers originated from advancements in polymer chemistry, transforming fabric technology and expanding applications in apparel and performance textiles.

Physical Properties: Strength and Flexibility

Nylon exhibits high tensile strength and excellent abrasion resistance, making it durable for heavy-duty applications, while spandex offers superior elasticity and stretchability, allowing for greater flexibility and movement. Nylon fibers maintain shape under stress and resist wear, whereas spandex can stretch up to 500% of its original length without breaking. Combining nylon with spandex often results in fabrics that balance strength and flexibility, ideal for activewear and performance garments.

Moisture Management and Breathability

Nylon fibers excel in moisture management by efficiently wicking sweat away from the skin, promoting quicker evaporation and keeping the wearer dry during intense activities. Spandex, while offering exceptional stretch and comfort, has limited breathability and moisture-wicking properties compared to nylon. Combining nylon's moisture control with spandex's elasticity results in fabric blends ideal for activewear that balances sweat management with flexibility.

Comfort and Fit: Stretch and Recovery

Nylon offers durability and smooth texture while providing moderate stretch, making it ideal for lightweight, breathable garments. Spandex excels in stretch and recovery, allowing fabrics to conform closely to the body for superior comfort and freedom of movement. Combining nylon with spandex enhances fit by balancing resilience with elasticity, ensuring garments maintain shape without sacrificing softness.

Durability and Longevity Comparisons

Nylon boasts exceptional durability due to its high tensile strength and resistance to abrasion, making it ideal for long-lasting fabrics in activewear and outdoor gear. Spandex offers superior elasticity and shape retention but tends to degrade faster under UV exposure and repeated stretching, impacting its longevity. Combining nylon with spandex often enhances fabric durability while maintaining flexibility, ideal for garments requiring both strength and stretch.

Common Applications in Fashion and Industry

Nylon is widely used in fashion for durable outerwear, hosiery, and swimwear due to its strength and resistance to abrasion. Spandex is preferred in activewear, leggings, and intimate apparel for its exceptional elasticity and shape retention. In industry, nylon finds applications in tire cords and parachutes, while spandex is utilized in medical compression garments and performance athletic wear.

Care Instructions for Nylon vs Spandex Garments

Nylon garments require gentle washing in cold water with mild detergent to preserve fabric strength and prevent pilling, while Spandex fabrics need low-temperature washing to maintain elasticity and avoid fabric damage. Both materials should be air-dried away from direct sunlight to prevent fiber degradation and loss of stretch. Avoid bleach and fabric softeners on Nylon and Spandex to extend garment lifespan and maintain breathability.

Environmental Impact and Sustainability

Nylon production relies heavily on petrochemicals, resulting in high carbon emissions and non-biodegradable waste, which poses significant environmental challenges. Spandex manufacturing also depends on synthetic polymers but generally uses less energy and produces fewer pollutants compared to nylon. Both materials raise sustainability concerns, though innovations in recycling technologies and bio-based alternatives aim to reduce their ecological footprints.

Nylon vs Spandex Infographic

materialdif.com

materialdif.com