Microfiber consists of synthetic fibers finer than silk, offering durability and moisture-wicking properties, while nanofiber features even thinner fibers measured at the nanometer scale, providing superior filtration and breathability. Microfiber fabrics are widely used in cleaning cloths and activewear due to their softness and absorbency, whereas nanofiber materials are prominent in advanced filtration and medical applications for their high surface area and filtration efficiency. Choosing between microfiber and nanofiber depends on the intended use, balancing factors like strength, flexibility, filtration needs, and production cost.

Table of Comparison

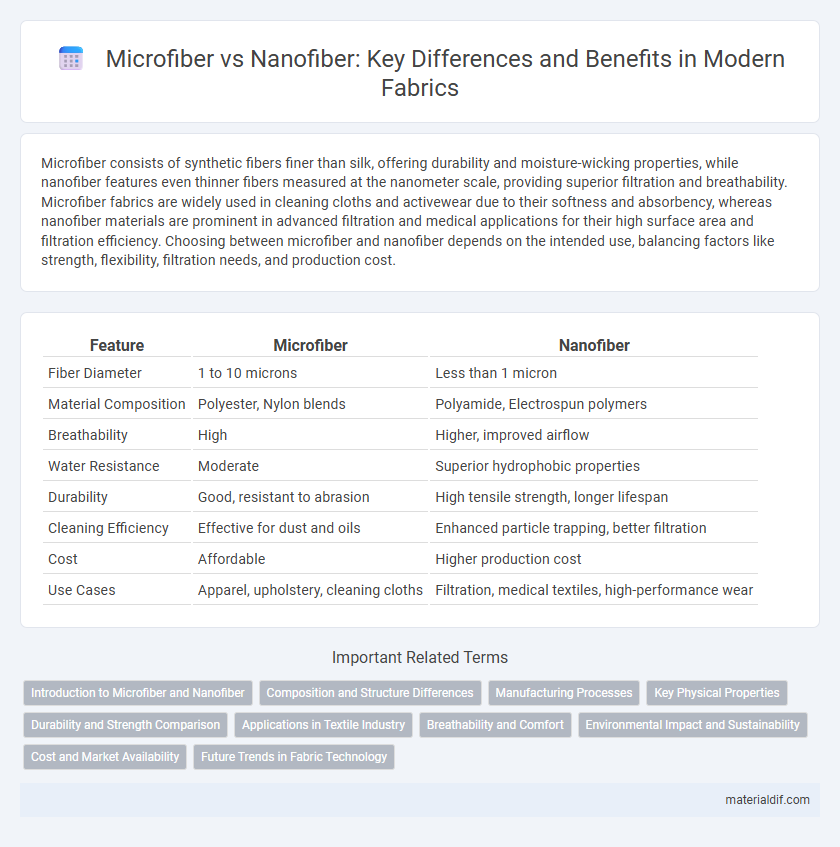

| Feature | Microfiber | Nanofiber |

|---|---|---|

| Fiber Diameter | 1 to 10 microns | Less than 1 micron |

| Material Composition | Polyester, Nylon blends | Polyamide, Electrospun polymers |

| Breathability | High | Higher, improved airflow |

| Water Resistance | Moderate | Superior hydrophobic properties |

| Durability | Good, resistant to abrasion | High tensile strength, longer lifespan |

| Cleaning Efficiency | Effective for dust and oils | Enhanced particle trapping, better filtration |

| Cost | Affordable | Higher production cost |

| Use Cases | Apparel, upholstery, cleaning cloths | Filtration, medical textiles, high-performance wear |

Introduction to Microfiber and Nanofiber

Microfiber and nanofiber are advanced synthetic fibers differentiated by their diameter size, with microfiber typically measuring less than 10 micrometers and nanofiber less than 1 micrometer. Both fibers are engineered for high surface area and enhanced filtration, but nanofibers offer superior breathability and finer particle filtration due to their ultrafine structure. These properties make microfiber and nanofiber ideal for applications in textiles, medical devices, and environmental filters.

Composition and Structure Differences

Microfiber is composed of synthetic fibers typically measuring less than 10 micrometers in diameter, made from polyester or polyamide blends, whereas nanofiber features ultrafine fibers with diameters below 100 nanometers, often produced via electrospinning techniques. The structural differences result in microfiber having a dense, woven fabric structure while nanofiber exhibits a highly porous, nonwoven network that enhances filtration and breathability. These compositional and structural variations influence absorbency, strength, and applications across textile and filtration industries.

Manufacturing Processes

Microfiber is produced through a melt extrusion process, where synthetic polymers like polyester or nylon are melted and forced through spinnerets to form fine fibers typically less than 1 denier in diameter. Nanofiber manufacturing employs electrospinning, which uses high-voltage electric fields to draw ultrafine fibers, often below 100 nanometers, from polymer solutions or melts, resulting in fibers with significantly higher surface area and porosity. These distinct processes influence the fiber morphology, with microfiber favoring bulk mass production and nanofiber enabling precise control over fiber diameter and functional properties.

Key Physical Properties

Microfiber consists of fibers with diameters typically between 0.1 and 1 denier, providing excellent softness, durability, and moisture-wicking properties, while nanofiber features even finer fibers below 100 nanometers, resulting in superior filtration efficiency, lightweight texture, and enhanced breathability. The smaller diameter of nanofibers leads to increased surface area and porosity, making them ideal for applications requiring high filtration performance and water resistance. Physical properties such as tensile strength, flexibility, and water repellency vary significantly between microfiber and nanofiber, influencing their suitability for apparel, cleaning materials, and industrial uses.

Durability and Strength Comparison

Microfiber fabrics, typically composed of synthetic fibers like polyester or nylon, offer high durability and resistance to wear due to their dense weave and fine fiber diameter, making them ideal for heavy-use applications. In contrast, nanofiber materials, characterized by even finer fibers at the nanoscale, provide enhanced strength-to-weight ratios and improved tensile strength but may require specialized manufacturing processes to achieve comparable durability over time. Both fabrics excel in strength, but microfibers generally outperform nanofibers in abrasion resistance and long-term durability under repeated stress.

Applications in Textile Industry

Microfiber and nanofiber fabrics revolutionize the textile industry through distinct applications driven by their fiber diameters, with microfibers typically ranging from 0.1 to 10 microns and nanofibers being less than 100 nanometers. Microfiber textiles excel in moisture-wicking, stain resistance, and durability, making them ideal for sportswear, upholstery, and cleaning cloths, while nanofiber materials are prized for their filtration efficiency, breathability, and antibacterial properties, essential in protective clothing and medical textiles. Advances in electrospinning technology enable the production of nanofibers with enhanced surface area and porosity, expanding their use in smart textiles and high-performance technical fabrics.

Breathability and Comfort

Microfiber fabrics, composed of fibers finer than silk but thicker than nanofibers, offer moderate breathability and softness ideal for everyday comfort. Nanofiber textiles feature ultra-fine fiber diameters, creating denser weaves that enhance moisture-wicking and airflow regulation, resulting in superior breathability and lightweight comfort. These properties make nanofiber materials particularly effective in activewear and performance fabrics where ventilation and comfort are critical.

Environmental Impact and Sustainability

Microfiber fabrics, composed of polyester or nylon fibers finer than human hair, often shed microplastics during washing, contributing to ocean pollution and posing risks to marine life. Nanofiber textiles, made using electrospinning techniques, offer comparable or superior filtration properties with the potential for biodegradable polymers, reducing environmental footprint when sourced responsibly. Sustainable fabric innovation emphasizes the use of biodegradable nanofibers and improved wastewater treatment to mitigate microplastic contamination linked to traditional microfiber use.

Cost and Market Availability

Microfiber fabrics, typically made from polyester or polyamide, are more widely available and cost-effective due to established large-scale production processes. Nanofiber textiles, made through electrospinning techniques, often incur higher costs because of complex manufacturing and limited commercial availability. The market favors microfiber for everyday applications, while nanofiber remains niche and specialized, influencing price and accessibility.

Future Trends in Fabric Technology

Microfiber and nanofiber technologies are driving the future of fabric innovation by enhancing durability, breathability, and moisture-wicking properties. Nanofibers offer superior filtration and antimicrobial capabilities due to their ultra-fine structures, making them ideal for advanced protective wear and smart textiles. Market research predicts a significant growth in nanofiber applications, with a CAGR exceeding 10% by 2030, fueled by demand in medical, sportswear, and environmental sectors.

Microfiber vs Nanofiber Infographic

materialdif.com

materialdif.com