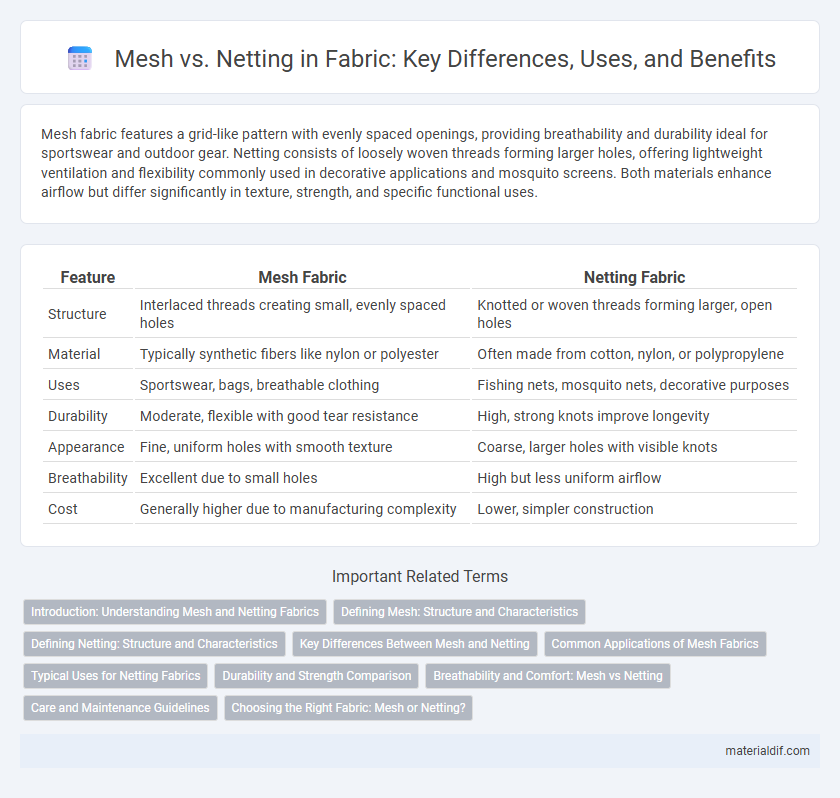

Mesh fabric features a grid-like pattern with evenly spaced openings, providing breathability and durability ideal for sportswear and outdoor gear. Netting consists of loosely woven threads forming larger holes, offering lightweight ventilation and flexibility commonly used in decorative applications and mosquito screens. Both materials enhance airflow but differ significantly in texture, strength, and specific functional uses.

Table of Comparison

| Feature | Mesh Fabric | Netting Fabric |

|---|---|---|

| Structure | Interlaced threads creating small, evenly spaced holes | Knotted or woven threads forming larger, open holes |

| Material | Typically synthetic fibers like nylon or polyester | Often made from cotton, nylon, or polypropylene |

| Uses | Sportswear, bags, breathable clothing | Fishing nets, mosquito nets, decorative purposes |

| Durability | Moderate, flexible with good tear resistance | High, strong knots improve longevity |

| Appearance | Fine, uniform holes with smooth texture | Coarse, larger holes with visible knots |

| Breathability | Excellent due to small holes | High but less uniform airflow |

| Cost | Generally higher due to manufacturing complexity | Lower, simpler construction |

Introduction: Understanding Mesh and Netting Fabrics

Mesh fabric features an open weave with evenly spaced holes that allow breathability and flexibility, making it ideal for sportswear and outdoor gear. Netting fabric, characterized by its knotted or looped construction, provides strength and durability suitable for applications like fishing nets and decorative overlays. Differentiating mesh and netting fabrics involves examining their structural patterns and functional uses in various textile industries.

Defining Mesh: Structure and Characteristics

Mesh fabric features an open weave construction formed by interlocking yarns or threads that create a grid-like pattern, allowing for excellent breathability and airflow. Typically made from materials such as polyester, nylon, or cotton, mesh is lightweight and flexible, designed for applications requiring ventilation and moisture-wicking properties. Its structure differentiates it from netting by having more uniform openings and a smoother, softer texture suited for sportswear, outdoor gear, and industrial uses.

Defining Netting: Structure and Characteristics

Netting is a fabric characterized by an open, grid-like structure formed by knots or interlaced threads, creating a stable and flexible material. Unlike mesh, netting often features larger openings and varied patterns, providing enhanced breathability and lightweight properties. Commonly used in applications such as fishing nets, sports gear, and decorative textiles, netting balances durability with ventilation.

Key Differences Between Mesh and Netting

Mesh features a woven or knitted structure with evenly spaced holes, providing flexibility and breathability, making it ideal for clothing and sportswear. Netting is constructed from twisted, knotted, or looped threads creating larger, open spaces primarily used for industrial, agricultural, or decorative applications. The key differences lie in their manufacturing techniques, hole size, durability, and intended use, with mesh offering a softer, stretchable fabric compared to the more rigid and durable netting.

Common Applications of Mesh Fabrics

Mesh fabrics are widely used in sportswear and outdoor gear due to their breathability and moisture-wicking properties. They are essential in items like athletic jerseys, backpacks, and protective gear, providing durability and ventilation. The structured open weave of mesh enhances airflow, making it ideal for applications requiring lightweight and breathable materials.

Typical Uses for Netting Fabrics

Netting fabrics are commonly used in sportswear, lingerie, and outdoor gear due to their lightweight and breathable properties. They provide excellent ventilation and durability for applications such as mosquito nets, decorative overlays, and garment linings. Netting is also favored in agricultural and industrial contexts where its open, flexible structure supports protection and filtration needs.

Durability and Strength Comparison

Mesh fabric typically offers greater durability and tensile strength due to its tightly woven structure, making it ideal for heavy-duty applications. Netting, characterized by its open-hole pattern, provides less resistance to tearing but excels in lightweight, breathable uses where flexibility is prioritized over ruggedness. While mesh can withstand higher stress levels and abrasive conditions, netting is preferred for tasks requiring ventilation and minimal weight, highlighting a clear trade-off between strength and breathability.

Breathability and Comfort: Mesh vs Netting

Mesh fabric offers superior breathability due to its larger, open weave structure that allows for enhanced air circulation, making it ideal for activewear and sports equipment. Netting features smaller holes and tighter construction, providing more durability but slightly reduced airflow compared to mesh. Both fabrics prioritize comfort, but mesh excels when ventilation and moisture management are critical.

Care and Maintenance Guidelines

Mesh fabric requires gentle washing in cold water and air drying to maintain its breathable structure and prevent stretching or tearing. Netting should be hand washed with mild detergent and laid flat to dry, preserving its delicate open weave and preventing deformation. Avoid using bleach or high heat on both fabrics to extend their lifespan and retain durability.

Choosing the Right Fabric: Mesh or Netting?

Mesh fabric features a structured, grid-like pattern offering durability and breathability, ideal for sportswear and outdoor gear. Netting fabric, characterized by its open holes and lightweight construction, excels in decorative uses and applications requiring ventilation, such as veils and insect screens. Selecting mesh or netting depends on the balance between strength, airflow, and aesthetic requirements specific to the project.

Mesh vs Netting Infographic

materialdif.com

materialdif.com