Ring-spun cotton offers superior softness and strength due to its finely twisted fibers, making it ideal for high-quality textiles and durable clothing. Open-end cotton, produced through a faster and more economical process, results in coarser yarns with less tensile strength but is well-suited for bulk production and cost-effective products. Choosing between ring-spun and open-end cotton depends on the balance between fabric softness, durability, and manufacturing efficiency required for the end use.

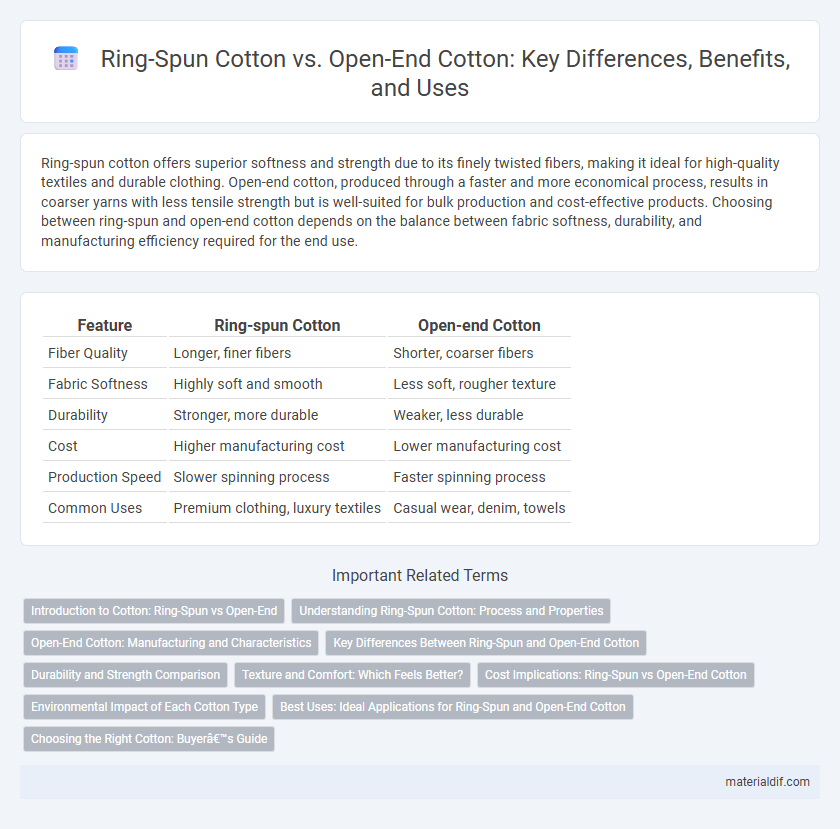

Table of Comparison

| Feature | Ring-spun Cotton | Open-end Cotton |

|---|---|---|

| Fiber Quality | Longer, finer fibers | Shorter, coarser fibers |

| Fabric Softness | Highly soft and smooth | Less soft, rougher texture |

| Durability | Stronger, more durable | Weaker, less durable |

| Cost | Higher manufacturing cost | Lower manufacturing cost |

| Production Speed | Slower spinning process | Faster spinning process |

| Common Uses | Premium clothing, luxury textiles | Casual wear, denim, towels |

Introduction to Cotton: Ring-Spun vs Open-End

Ring-spun cotton fibers are twisted tightly to create stronger, finer yarns that produce softer and more durable textiles, commonly used in high-quality apparel and bedding. Open-end cotton utilizes a faster, less labor-intensive spinning process that results in coarser, bulkier yarn, ideal for products like denim and towels where affordability and texture are prioritized. Understanding the structural differences between ring-spun and open-end cotton enhances fabric selection based on desired softness, strength, and cost-effectiveness.

Understanding Ring-Spun Cotton: Process and Properties

Ring-spun cotton is produced by continuously twisting and thinning cotton fibers to create a strong, fine yarn with a smooth texture. This process results in fabric that is more durable, softer, and more breathable compared to open-end cotton, which uses a different method that produces a coarser and less resilient yarn. The enhanced strength and superior hand feel of ring-spun cotton make it ideal for premium textiles and high-quality clothing.

Open-End Cotton: Manufacturing and Characteristics

Open-end cotton is produced through a high-speed spinning process that involves feeding slivers into a rotor, where fibers are separated and twisted into yarn without the need for a spindle, resulting in faster and more cost-effective manufacturing. The yarn produced is typically coarser, with lower tensile strength and a rougher texture compared to ring-spun cotton, making it suitable for products like denim, towels, and industrial textiles. Its manufacturing efficiency and durability make open-end cotton a preferred choice for heavy-duty fabrics requiring bulk and absorbency.

Key Differences Between Ring-Spun and Open-End Cotton

Ring-spun cotton fibers undergo a twisting and thinning process that produces a finer, stronger, and softer fabric, making it ideal for premium garments and textiles. In contrast, open-end cotton uses a more efficient spinning method that creates thicker, coarser yarns with less tensile strength, commonly used for durable and cost-effective products. The key differences lie in the fiber quality, yarn strength, texture, and production speed, with ring-spun cotton prioritizing softness and durability, while open-end cotton emphasizes manufacturing efficiency and affordability.

Durability and Strength Comparison

Ring-spun cotton fibers are longer and twisted more tightly, resulting in greater durability and higher tensile strength compared to open-end cotton. Open-end cotton, produced through a faster, less labor-intensive process, tends to have shorter, weaker fibers, making it less resistant to wear and tear over time. The enhanced fiber alignment in ring-spun cotton fabrics delivers superior performance in garments subjected to frequent washing and heavy use.

Texture and Comfort: Which Feels Better?

Ring-spun cotton offers a finer, softer texture due to its tightly twisted fibers, resulting in a smoother and more comfortable fabric ideal for sensitive skin. Open-end cotton has a coarser texture with a slightly rougher feel because of its less tightly spun fibers, making it more durable but less soft. For superior comfort and softness, ring-spun cotton is generally preferred over open-end cotton.

Cost Implications: Ring-Spun vs Open-End Cotton

Ring-spun cotton typically incurs higher production costs due to its intricate spinning process that results in finer, stronger yarns, making it more expensive than open-end cotton. Open-end cotton, produced through a faster, less labor-intensive method, offers a cost-effective alternative but generally compromises on fabric softness and durability. Manufacturers often balance these cost implications against quality requirements when selecting between ring-spun and open-end cotton for textile products.

Environmental Impact of Each Cotton Type

Ring-spun cotton typically consumes more water and energy during production due to its finer yarn spinning process, resulting in a higher environmental footprint compared to open-end cotton. Open-end cotton production is generally less resource-intensive and generates less waste, making it a more eco-friendly option for textile manufacturing. However, the durability and softness of ring-spun cotton often lead to longer garment lifespan, potentially offsetting some of its environmental impacts over time.

Best Uses: Ideal Applications for Ring-Spun and Open-End Cotton

Ring-spun cotton offers superior softness and strength, making it ideal for high-quality garments like t-shirts, dress shirts, and baby clothing where comfort and durability matter. Open-end cotton, characterized by its coarser texture and faster production, is best suited for budget-friendly items such as denim, towels, and workwear that require resilience over softness. Choosing between these fibers depends on the desired fabric feel, longevity, and end-use application.

Choosing the Right Cotton: Buyer’s Guide

Ring-spun cotton offers superior softness and durability due to its tightly twisted fibers, making it ideal for high-quality garments and textiles. Open-end cotton, produced through a faster spinning process, provides a coarser texture and is often more affordable, suitable for budget-friendly or industrial applications. Buyers should consider the end-use, desired fabric feel, and budget constraints to select the appropriate cotton type for their product.

Ring-spun Cotton vs Open-end Cotton Infographic

materialdif.com

materialdif.com