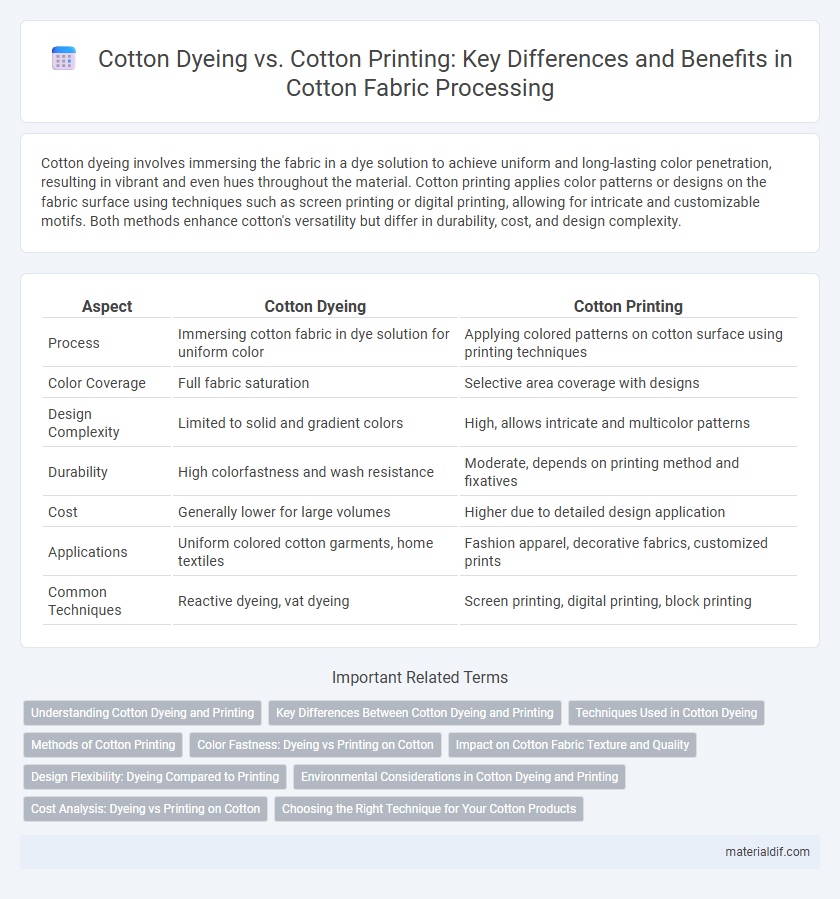

Cotton dyeing involves immersing the fabric in a dye solution to achieve uniform and long-lasting color penetration, resulting in vibrant and even hues throughout the material. Cotton printing applies color patterns or designs on the fabric surface using techniques such as screen printing or digital printing, allowing for intricate and customizable motifs. Both methods enhance cotton's versatility but differ in durability, cost, and design complexity.

Table of Comparison

| Aspect | Cotton Dyeing | Cotton Printing |

|---|---|---|

| Process | Immersing cotton fabric in dye solution for uniform color | Applying colored patterns on cotton surface using printing techniques |

| Color Coverage | Full fabric saturation | Selective area coverage with designs |

| Design Complexity | Limited to solid and gradient colors | High, allows intricate and multicolor patterns |

| Durability | High colorfastness and wash resistance | Moderate, depends on printing method and fixatives |

| Cost | Generally lower for large volumes | Higher due to detailed design application |

| Applications | Uniform colored cotton garments, home textiles | Fashion apparel, decorative fabrics, customized prints |

| Common Techniques | Reactive dyeing, vat dyeing | Screen printing, digital printing, block printing |

Understanding Cotton Dyeing and Printing

Cotton dyeing involves the application of color to the entire fabric, allowing for uniform and long-lasting hues achieved through processes like fiber, yarn, or piece dyeing. Cotton printing, on the other hand, applies designs onto fabric surfaces using techniques such as block printing, screen printing, or digital printing, offering intricate patterns and multi-color options. Understanding these methods highlights dyeing's role in creating consistent color saturation, while printing emphasizes design versatility and detail on cotton textiles.

Key Differences Between Cotton Dyeing and Printing

Cotton dyeing involves immersing the fabric in a dye solution to apply a uniform color throughout the fibers, resulting in a solid and consistent appearance, while cotton printing applies color specifically to targeted areas using techniques like screen printing or digital printing, creating patterns or designs on the surface. Dyeing penetrates the fibers, offering better color fastness and durability, whereas printing sits atop the fabric, often requiring fixatives to enhance longevity. Key differences include the method of color application, with dyeing being an all-over process and printing enabling localized design work, influencing texture, cost, and production time.

Techniques Used in Cotton Dyeing

Cotton dyeing techniques primarily involve fiber dyeing, yarn dyeing, and piece dyeing, with reactive dyes being the most common due to their strong affinity for cellulose fibers. Techniques such as vat dyeing, where the fabric is immersed in a dye bath, and screen printing for localized color application are essential for achieving vibrant and long-lasting colors. Advanced methods like digital inkjet printing utilize pigment or reactive dyes, offering precise color control while maintaining fabric softness and colorfastness.

Methods of Cotton Printing

Cotton printing involves applying patterns or designs onto fabric using techniques such as block printing, screen printing, and digital printing, each offering distinct advantages in precision and color vibrancy. Block printing is a traditional method where carved wooden blocks stamp dye onto the fabric, while screen printing uses a mesh to transfer ink through stencils for cleaner, more detailed designs. Digital printing enables high-resolution images and complex patterns directly on cotton, optimizing efficiency and reducing water usage compared to conventional dyeing methods.

Color Fastness: Dyeing vs Printing on Cotton

Cotton dyeing penetrates fibers deeply, resulting in superior color fastness compared to cotton printing, where pigments primarily adhere to the fabric surface. Dyeing methods such as reactive or vat dyeing create chemical bonds with cotton fibers, enhancing resistance to washing, light, and rubbing. In contrast, printed cotton fabrics often experience faster color fading and reduced durability due to weaker pigment attachment and surface-level color application.

Impact on Cotton Fabric Texture and Quality

Cotton dyeing penetrates the fibers uniformly, resulting in a smooth, consistent texture that maintains the fabric's natural softness and breathability. In contrast, cotton printing applies color on the surface, which can lead to a slightly stiffer hand feel and potential changes in texture depending on the printing technique used. The overall quality of cotton fabric remains intact with dyeing due to deep fiber infusion, whereas printing may affect durability and colorfastness over time, especially with frequent washing.

Design Flexibility: Dyeing Compared to Printing

Cotton dyeing offers superior color penetration and uniformity, allowing for rich, long-lasting hues that can be applied across the entire fabric. In contrast, cotton printing provides more precise design flexibility with intricate patterns and multiple colors but typically only affects the fabric's surface. Dyeing is ideal for solid, uniform colors, while printing excels in creating detailed, complex designs and artistic effects on cotton textiles.

Environmental Considerations in Cotton Dyeing and Printing

Cotton dyeing often involves high water and chemical usage, leading to significant environmental pollution if not managed properly, whereas cotton printing typically uses less water and allows for more precise application of pigments, reducing waste. Both processes can benefit from eco-friendly alternatives such as low-impact dyes and waterless printing technologies to minimize harmful effluents and energy consumption. Implementing sustainable practices in cotton dyeing and printing is crucial for reducing the textile industry's ecological footprint and promoting environmental conservation.

Cost Analysis: Dyeing vs Printing on Cotton

Cotton dyeing generally incurs higher initial costs due to the extensive use of water, chemicals, and energy required for uniform color absorption, whereas cotton printing involves lower upfront expenses by applying designs selectively, minimizing resource consumption. However, printing allows for greater design flexibility and reduced waste, making it more cost-effective for small batches or customized orders compared to dyeing's efficiency in large-scale solid color production. The overall cost analysis depends on factors like production volume, design complexity, and resource availability, with dyeing favored for bulk single-color needs and printing preferred for detailed multicolor patterns and shorter runs.

Choosing the Right Technique for Your Cotton Products

Cotton dyeing penetrates fibers, providing uniform, long-lasting color ideal for solid-colored garments, while cotton printing applies designs on the fabric surface, allowing intricate patterns and multicolor effects. Selecting the right technique depends on the desired aesthetic, usage, and durability; dyeing ensures colorfastness and depth, whereas printing offers versatility in design customization. Consider the end product's function and visual appeal to optimize the choice between cotton dyeing and cotton printing for quality and performance.

Cotton Dyeing vs Cotton Printing Infographic

materialdif.com

materialdif.com