Compact cotton fibers are longer, stronger, and more uniform than regular cotton, resulting in smoother fabric with fewer imperfections. This enhanced fiber quality improves yarn strength and reduces pilling, making compact cotton ideal for high-quality textiles. Manufacturers prefer compact cotton for producing durable, premium garments that maintain their appearance after multiple washes.

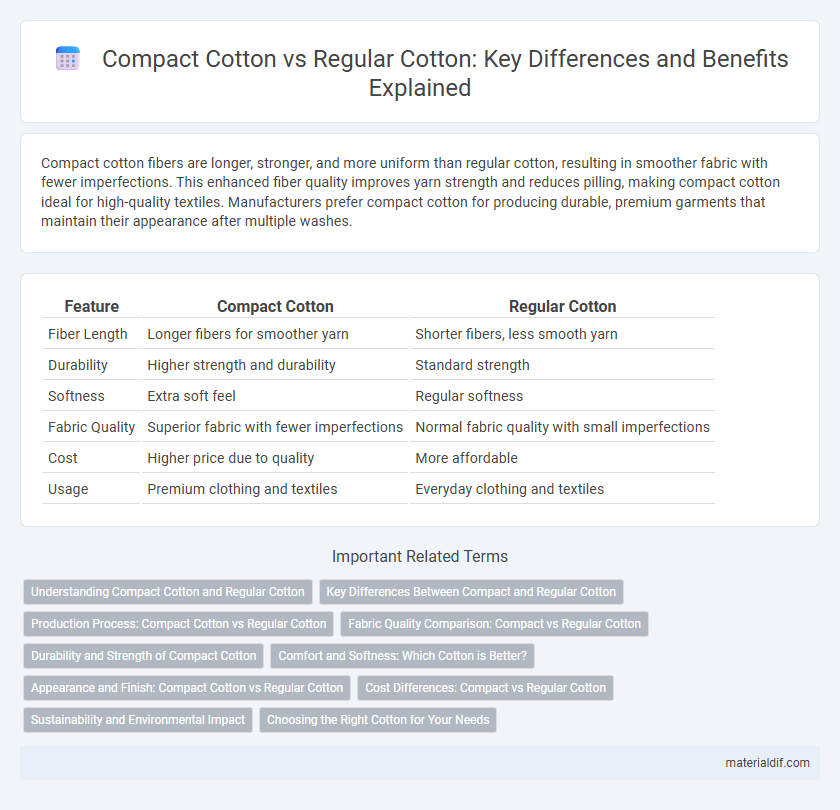

Table of Comparison

| Feature | Compact Cotton | Regular Cotton |

|---|---|---|

| Fiber Length | Longer fibers for smoother yarn | Shorter fibers, less smooth yarn |

| Durability | Higher strength and durability | Standard strength |

| Softness | Extra soft feel | Regular softness |

| Fabric Quality | Superior fabric with fewer imperfections | Normal fabric quality with small imperfections |

| Cost | Higher price due to quality | More affordable |

| Usage | Premium clothing and textiles | Everyday clothing and textiles |

Understanding Compact Cotton and Regular Cotton

Compact cotton fibers are harvested using advanced spinning technology that condenses and aligns the fibers more uniformly, resulting in smoother, stronger, and finer yarn compared to regular cotton. Regular cotton involves traditional spinning methods where fibers are less aligned, leading to yarns that may be coarser and less durable. This difference enhances fabric quality in compact cotton products, offering better breathability, softness, and longevity than fabrics made from regular cotton.

Key Differences Between Compact and Regular Cotton

Compact cotton fibers are produced using advanced spinning technology that condenses the fibers, resulting in fewer protruding ends, increased strength, and smoother, finer yarn compared to regular cotton. Regular cotton fibers have a typical staple length with more fiber ends causing higher hairiness and less durability in the fabric. The key difference lies in compact cotton's ability to create denser and more uniform yarns, enhancing fabric quality, longevity, and softness.

Production Process: Compact Cotton vs Regular Cotton

Compact cotton is produced using an advanced spinning technology that shortens and condenses fibers before twisting, resulting in fewer fiber ends protruding from the yarn. Regular cotton employs a traditional open-end spinning process where longer fibers are less compacted, leading to more fiber ends sticking out. This difference in production results in compact cotton yarns that are stronger, smoother, and less prone to pilling compared to regular cotton yarns.

Fabric Quality Comparison: Compact vs Regular Cotton

Compact cotton fabric exhibits a tighter yarn structure compared to regular cotton, resulting in a smoother, stronger, and more durable material with fewer imperfections. This enhanced yarn uniformity reduces pilling and improves the fabric's overall softness and color retention. Consequently, compact cotton is preferred for high-quality garments that demand superior longevity and comfort.

Durability and Strength of Compact Cotton

Compact cotton fibers exhibit enhanced durability and superior strength compared to regular cotton due to their longer staple length and reduced fiber neps. This results in fabrics that resist pilling and tearing more effectively, offering prolonged wear and maintaining their appearance over time. The increased fiber density in compact cotton contributes to a smoother, more resilient textile ideal for high-performance apparel and premium textiles.

Comfort and Softness: Which Cotton is Better?

Compact cotton features longer, more aligned fibers that result in a smoother, softer fabric compared to regular cotton. This fiber structure enhances comfort by reducing friction against the skin and increasing durability, making it ideal for sensitive skin and everyday wear. Regular cotton, while breathable and soft, lacks the refined fiber alignment of compact cotton, which can lead to a coarser texture over time.

Appearance and Finish: Compact Cotton vs Regular Cotton

Compact cotton fibers produce a smoother and more uniform yarn, resulting in a fabric with a refined appearance and enhanced luster compared to regular cotton. This difference in fiber structure reduces protruding ends and pilling, giving compact cotton fabrics a cleaner, glossier finish. Regular cotton, with its less controlled fiber alignment, typically has a rougher texture and a matte finish, which can lead to a more casual or rustic look in the final textile.

Cost Differences: Compact vs Regular Cotton

Compact cotton typically incurs higher costs than regular cotton due to its superior fiber strength, reduced short fiber content, and improved uniformity, which enhance fabric quality and durability. The advanced processing technology required for compact cotton production contributes to increased manufacturing expenses, resulting in a price premium. Despite the higher initial cost, compact cotton's enhanced performance often justifies the investment in premium textile applications.

Sustainability and Environmental Impact

Compact cotton fibers are produced through enhanced spinning techniques that reduce fiber breakage, resulting in stronger yarn with less waste compared to regular cotton. This increased fiber efficiency means fewer raw materials are needed, lowering water consumption, pesticide usage, and carbon emissions linked to cotton cultivation. The sustainability benefits of compact cotton extend to reducing the environmental impact throughout the textile supply chain by minimizing resource-intensive processes and increasing fabric durability.

Choosing the Right Cotton for Your Needs

Compact cotton offers superior strength, reduced pilling, and a smoother texture compared to regular cotton, making it ideal for durable, high-quality garments. Regular cotton remains a cost-effective choice with excellent breathability and softness, suitable for everyday wear and basic textiles. Selecting the right cotton depends on the desired balance between durability, comfort, and budget for your specific textile or apparel needs.

Compact Cotton vs Regular Cotton Infographic

materialdif.com

materialdif.com