Bamboo filament offers a natural, eco-friendly alternative to PLA filament, providing enhanced strength and flexibility for 3D printing projects while maintaining biodegradability. Unlike PLA, which is derived from cornstarch and often features a smoother finish, bamboo filament incorporates actual bamboo fibers, giving prints a unique texture and organic appearance. Both materials are sustainable options, but bamboo filament stands out for its durability and distinct aesthetic qualities.

Table of Comparison

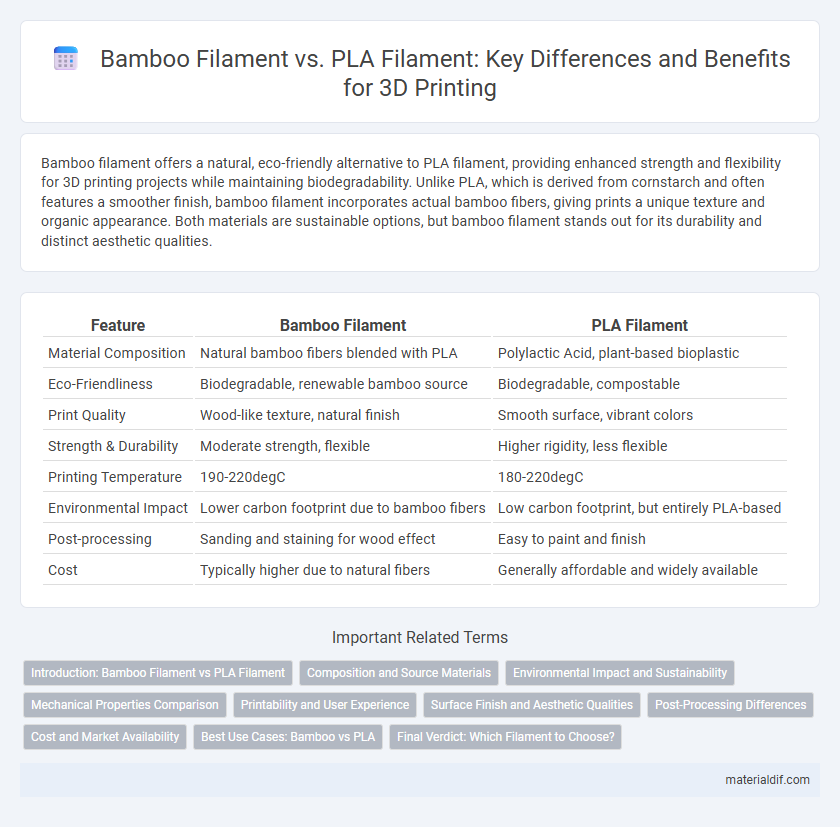

| Feature | Bamboo Filament | PLA Filament |

|---|---|---|

| Material Composition | Natural bamboo fibers blended with PLA | Polylactic Acid, plant-based bioplastic |

| Eco-Friendliness | Biodegradable, renewable bamboo source | Biodegradable, compostable |

| Print Quality | Wood-like texture, natural finish | Smooth surface, vibrant colors |

| Strength & Durability | Moderate strength, flexible | Higher rigidity, less flexible |

| Printing Temperature | 190-220degC | 180-220degC |

| Environmental Impact | Lower carbon footprint due to bamboo fibers | Low carbon footprint, but entirely PLA-based |

| Post-processing | Sanding and staining for wood effect | Easy to paint and finish |

| Cost | Typically higher due to natural fibers | Generally affordable and widely available |

Introduction: Bamboo Filament vs PLA Filament

Bamboo filament combines natural bamboo fibers with PLA base material, enhancing strength, flexibility, and sustainability compared to standard PLA filament. This eco-friendly alternative offers a unique wood-like finish and improved biodegradability while maintaining the ease of printing associated with PLA. Ideal for environmentally conscious 3D printing projects, bamboo filament balances aesthetic appeal with material performance.

Composition and Source Materials

Bamboo filament is composed of a blend of bamboo fibers and biodegradable PLA (polylactic acid), derived from natural bamboo plants and cornstarch-based polymers. PLA filament is made purely from renewable plant starch, primarily corn or sugarcane, without natural fiber additives. The integration of bamboo fibers in bamboo filament enhances rigidity and imparts a wood-like texture compared to the smooth finish of standard PLA filament.

Environmental Impact and Sustainability

Bamboo filament offers superior environmental benefits compared to PLA filament due to its rapid growth rate and minimal agricultural inputs, resulting in lower carbon emissions and reduced deforestation risks. Unlike PLA, which is derived from corn starch and relies heavily on industrial farming with fertilizer and pesticide use, bamboo filament's production utilizes sustainable harvesting without significant land degradation. The biodegradability of bamboo filament is enhanced by its natural fibers, promoting faster decomposition in composting environments, making it a more sustainable choice for eco-friendly 3D printing.

Mechanical Properties Comparison

Bamboo filament exhibits superior tensile strength and higher impact resistance compared to PLA filament, making it ideal for durable and flexible 3D printing applications. The natural fiber content in bamboo filament enhances stiffness and improves thermal stability, while PLA filament offers lower elongation at break and reduced heat resistance. Mechanical tests show bamboo filament can withstand greater stress and deformation, contributing to longer-lasting printed parts under mechanical load.

Printability and User Experience

Bamboo filament offers superior printability compared to PLA filament due to its natural fibers, which provide excellent layer adhesion and reduced warping, resulting in smoother and more durable prints. Users often prefer bamboo filament for its eco-friendliness and the unique wood-like texture it imparts, enhancing the tactile and visual quality of 3D-printed objects. PLA filament is easier to print at lower temperatures with minimal warping, making it ideal for beginners, but it lacks the aesthetic appeal and environmental benefits that bamboo filament provides.

Surface Finish and Aesthetic Qualities

Bamboo filament offers a natural, wood-like surface finish with unique grain patterns and subtle color variations that enhance aesthetic appeal, making prints appear more organic and textured compared to PLA filament. PLA filament typically produces smooth, glossy surfaces with consistent color, ideal for vibrant, precise details but lacking the warmth and character found in bamboo filament prints. The natural fibers in bamboo filament provide a tactile, matte finish that mimics real wood, perfect for decorative items and eco-friendly projects seeking a rustic or artisanal look.

Post-Processing Differences

Bamboo filament offers a unique post-processing advantage by allowing easier sanding and a more natural finish compared to PLA filament, which typically requires additional priming and painting to achieve similar aesthetics. Unlike PLA, bamboo filament can be stained or varnished to enhance its wood-like appearance, providing more versatility in the final product's texture and color. PLA filament tends to be more brittle after printing, necessitating careful handling during post-processing to avoid chipping or cracking.

Cost and Market Availability

Bamboo filament generally costs more than PLA filament due to the natural fiber content and eco-friendly processing methods, though prices vary based on supplier and quality. PLA filament remains widely available and significantly cheaper, dominating the market with broad accessibility for hobbyists and professionals alike. Bamboo filament's market presence is growing but remains niche, limiting its availability compared to the mass-produced PLA options.

Best Use Cases: Bamboo vs PLA

Bamboo filament offers superior biodegradability and a natural wood-like finish, making it ideal for eco-friendly products and decorative items such as furniture prototypes and artistic sculptures. PLA filament excels in precision and ease of printing, suited for detailed prototypes, functional parts, and educational models due to its dimensional stability and wide compatibility with 3D printers. For sustainable, aesthetic projects, bamboo filament is preferred, while PLA is optimal for functional and highly detailed components.

Final Verdict: Which Filament to Choose?

Bamboo filament offers a unique natural aesthetic and eco-friendly advantage compared to PLA filament, which is widely recognized for its ease of printing and consistent strength. For projects requiring sustainability and a wood-like finish, bamboo filament is preferred, while PLA remains ideal for detailed, reliable prints with minimal warping. Choosing between bamboo and PLA filaments depends on balancing environmental impact, print quality, and application-specific requirements.

Bamboo Filament vs PLA Filament Infographic

materialdif.com

materialdif.com