Sandblasting and bush hammering are both popular techniques used to texture stone surfaces, but they differ significantly in appearance and application. Sandblasting propels fine abrasive particles to create a uniformly rough, matte finish, ideal for subtle textural effects and enhancing slip resistance. Bush hammering involves pounding the stone with a specialized tool to produce a patterned, rugged surface, often preferred for creating a pronounced, decorative texture on stone facades and pavements.

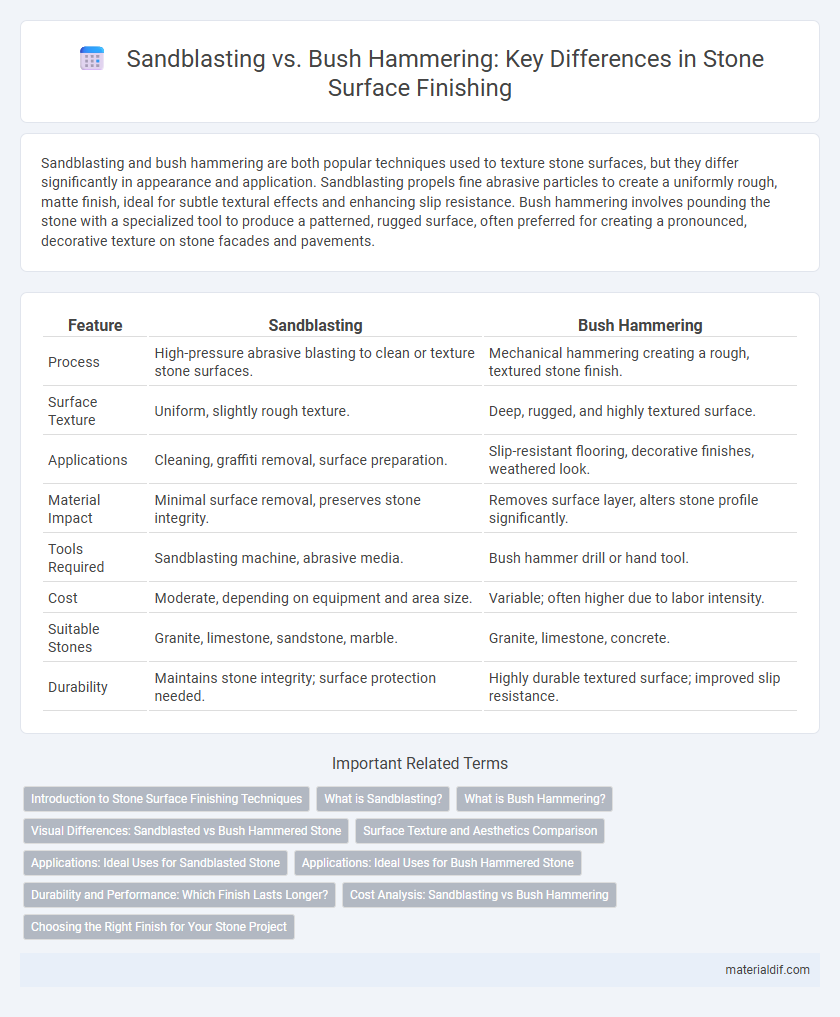

Table of Comparison

| Feature | Sandblasting | Bush Hammering |

|---|---|---|

| Process | High-pressure abrasive blasting to clean or texture stone surfaces. | Mechanical hammering creating a rough, textured stone finish. |

| Surface Texture | Uniform, slightly rough texture. | Deep, rugged, and highly textured surface. |

| Applications | Cleaning, graffiti removal, surface preparation. | Slip-resistant flooring, decorative finishes, weathered look. |

| Material Impact | Minimal surface removal, preserves stone integrity. | Removes surface layer, alters stone profile significantly. |

| Tools Required | Sandblasting machine, abrasive media. | Bush hammer drill or hand tool. |

| Cost | Moderate, depending on equipment and area size. | Variable; often higher due to labor intensity. |

| Suitable Stones | Granite, limestone, sandstone, marble. | Granite, limestone, concrete. |

| Durability | Maintains stone integrity; surface protection needed. | Highly durable textured surface; improved slip resistance. |

Introduction to Stone Surface Finishing Techniques

Sandblasting and bush hammering are popular stone surface finishing techniques that enhance texture and durability. Sandblasting uses high-pressure abrasive materials to create a uniform, matte finish ideal for decorative and architectural applications. Bush hammering involves mechanical hammering with multiple points to produce a rough, anti-slip surface, often used for stone pavements and exterior walls.

What is Sandblasting?

Sandblasting is a surface treatment technique that propels fine abrasive particles at high velocity to clean, etch, or texture stone surfaces. This method effectively removes dirt, paint, and weathered layers while enhancing the stone's natural texture and appearance. Commonly used on granite, limestone, and sandstone, sandblasting prepares stone for further finishing or creates a decorative matte finish.

What is Bush Hammering?

Bush hammering is a mechanical stone surface treatment that uses a specialized hammer equipped with rows of small, pyramid-shaped points to create a textured, rough finish. This technique enhances slip resistance and aesthetic appeal on natural stone, concrete, and terrazzo surfaces. Unlike sandblasting, which uses abrasive particles propelled at high velocity, bush hammering mechanically impacts the surface to produce deeper grooves and a more pronounced texture.

Visual Differences: Sandblasted vs Bush Hammered Stone

Sandblasted stone features a uniformly textured surface with a fine, grainy finish that enhances color depth and reduces reflectivity, making it ideal for achieving a matte look. Bush hammered stone displays a rough, hammered pattern characterized by small indentations and a pronounced, rugged texture that increases slip resistance and adds visual complexity. The stark contrast between sandblasted and bush hammered stone surfaces lies in the smooth, even texture of sandblasting compared to the coarse, patterned appearance of bush hammering.

Surface Texture and Aesthetics Comparison

Sandblasting creates a uniformly rough surface texture by propelling fine abrasive particles at high velocity, enhancing stone's natural color and producing a matte finish ideal for decorative and slip-resistant applications. Bush hammering involves hammering the stone's surface with a tool featuring multiple points, generating a more pronounced, pockmarked texture that emphasizes ruggedness and durability while providing greater traction. The choice between sandblasting and bush hammering impacts the stone's visual appeal and tactile experience, affecting architectural style and functional performance.

Applications: Ideal Uses for Sandblasted Stone

Sandblasted stone is ideal for exterior architectural surfaces such as building facades, walkways, and decorative panels where a uniform, non-slip texture is required. Its fine, matte finish enhances the natural grain of granite, sandstone, and limestone, making it suitable for signage and monuments that demand clear, legible text. Sandblasting also serves well in pool decks and outdoor stairs, providing safety through slip resistance without compromising aesthetic appeal.

Applications: Ideal Uses for Bush Hammered Stone

Bush hammered stone is ideal for creating non-slip surfaces in outdoor areas such as patios, walkways, and pool decks due to its textured, rough finish. This technique is often used in architectural projects requiring enhanced traction and aesthetic appeal on granite, limestone, and concrete surfaces. Its application extends to decorative facades and public spaces where durability and safety are paramount.

Durability and Performance: Which Finish Lasts Longer?

Sandblasting creates a textured surface by propelling fine abrasive particles at high velocity, offering moderate durability suited for decorative stone applications. Bush hammering, involving a mechanical tool with multiple pointed tips, produces a highly rugged and durable finish ideal for heavy-traffic stone surfaces requiring enhanced slip resistance. Stone treated with bush hammering generally lasts longer under harsh weather and wear conditions compared to sandblasted finishes due to its increased surface strength and resistance to erosion.

Cost Analysis: Sandblasting vs Bush Hammering

Sandblasting generally incurs lower initial costs compared to bush hammering due to simpler equipment and faster application times, making it more cost-effective for large surface areas. Bush hammering involves higher labor and machine expenses owing to its intensive mechanical action, resulting in increased project duration and maintenance requirements. When selecting between sandblasting and bush hammering, consider the total cost implications, including preparation, labor, equipment, and finish quality to optimize budget efficiency.

Choosing the Right Finish for Your Stone Project

Selecting the appropriate finish for your stone project depends on the desired texture and durability; sandblasting creates a smooth, matte surface by propelling fine abrasive particles, ideal for intricate designs and subtle details. Bush hammering produces a rugged, textured finish by mechanically pounding the stone, enhancing slip resistance and weathering properties, suitable for exterior flooring and high-traffic areas. Understanding the specific application and aesthetic goals ensures the choice between sandblasting and bush hammering maximizes both functionality and visual appeal.

Sandblasting vs Bush Hammering Infographic

materialdif.com

materialdif.com