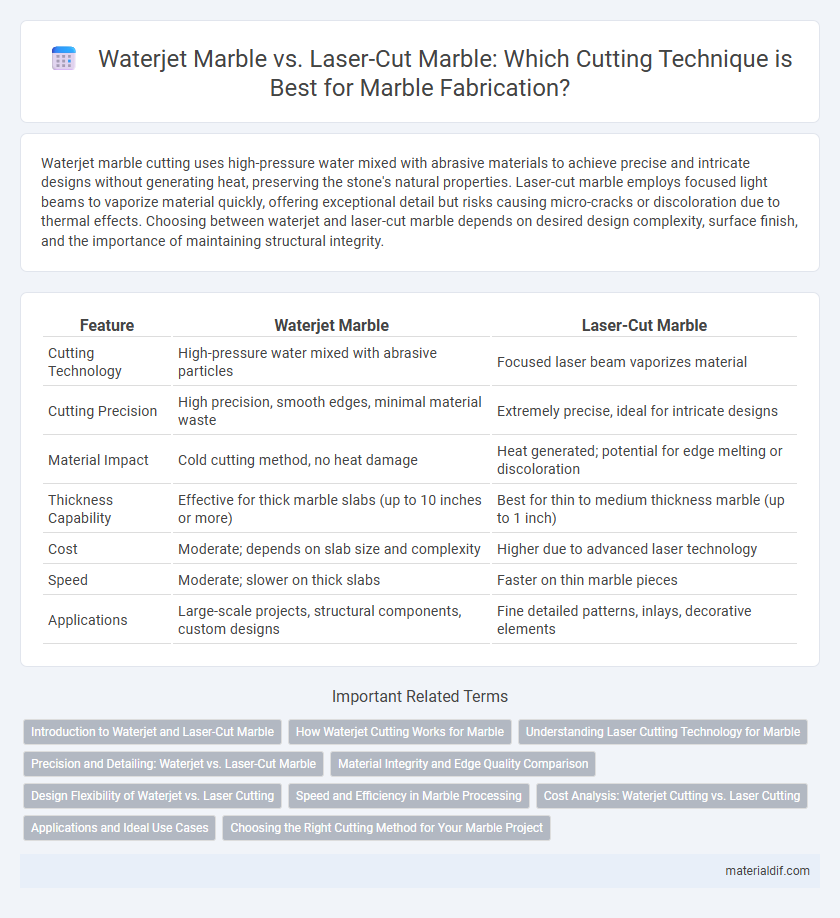

Waterjet marble cutting uses high-pressure water mixed with abrasive materials to achieve precise and intricate designs without generating heat, preserving the stone's natural properties. Laser-cut marble employs focused light beams to vaporize material quickly, offering exceptional detail but risks causing micro-cracks or discoloration due to thermal effects. Choosing between waterjet and laser-cut marble depends on desired design complexity, surface finish, and the importance of maintaining structural integrity.

Table of Comparison

| Feature | Waterjet Marble | Laser-Cut Marble |

|---|---|---|

| Cutting Technology | High-pressure water mixed with abrasive particles | Focused laser beam vaporizes material |

| Cutting Precision | High precision, smooth edges, minimal material waste | Extremely precise, ideal for intricate designs |

| Material Impact | Cold cutting method, no heat damage | Heat generated; potential for edge melting or discoloration |

| Thickness Capability | Effective for thick marble slabs (up to 10 inches or more) | Best for thin to medium thickness marble (up to 1 inch) |

| Cost | Moderate; depends on slab size and complexity | Higher due to advanced laser technology |

| Speed | Moderate; slower on thick slabs | Faster on thin marble pieces |

| Applications | Large-scale projects, structural components, custom designs | Fine detailed patterns, inlays, decorative elements |

Introduction to Waterjet and Laser-Cut Marble

Waterjet marble cutting utilizes high-pressure water mixed with abrasive materials to precisely slice through marble without causing heat damage, preserving the stone's natural integrity. Laser-cut marble employs focused laser beams to achieve intricate designs but may introduce thermal stress or slight discoloration on the surface. Waterjet offers superior versatility and cleaner edges for detailed patterns, while laser cutting excels in rapid execution on thinner marble slabs.

How Waterjet Cutting Works for Marble

Waterjet cutting for marble uses a high-pressure jet of water mixed with abrasive garnet particles to precisely cut through the dense stone. This technique preserves the marble's natural integrity by avoiding heat, which prevents cracking and discoloration common in laser cutting. The process allows intricate designs and smooth edges, making it ideal for detailed marble applications in architecture and art.

Understanding Laser Cutting Technology for Marble

Laser cutting technology for marble utilizes a high-powered laser beam that precisely vaporizes stone material, allowing intricate and detailed designs with smooth edges. This method provides superior accuracy and cleaner cuts compared to traditional waterjet cutting, minimizing material wastage and reducing post-processing efforts. Laser cutting is especially effective for thin marble slabs and delicate patterns, offering enhanced control over engraving depth and edge quality.

Precision and Detailing: Waterjet vs. Laser-Cut Marble

Waterjet marble cutting offers superior precision by using a high-pressure stream of water mixed with abrasive particles, enabling intricate detailing without heat damage. Laser-cut marble provides fine, sharp edges and excellent repeatability but may cause micro-cracks or discoloration due to thermal effects. For projects requiring delicate, complex patterns with pristine surface integrity, waterjet cutting is typically preferred over laser-cutting techniques.

Material Integrity and Edge Quality Comparison

Waterjet marble cutting preserves material integrity by minimizing heat exposure, preventing thermal stress and micro-cracks, which are common in laser-cut marble due to high temperatures. Edge quality in waterjet cutting is typically smoother and more precise, with minimal chipping or discoloration, while laser cutting can cause slight melting or rough edges from uneven heat distribution. Selecting waterjet technology ensures superior structural stability and cleaner edges, ideal for intricate marble designs requiring high durability.

Design Flexibility of Waterjet vs. Laser Cutting

Waterjet cutting offers superior design flexibility for marble, enabling intricate patterns and complex shapes without thermal stress or material distortion. Unlike laser cutting, which is limited by heat-affected zones and less effective on thicker marble slabs, waterjet technology accommodates diverse thicknesses and maintains edge quality. This precision versatility makes waterjet the preferred method for detailed, high-quality marble craftsmanship.

Speed and Efficiency in Marble Processing

Waterjet marble cutting offers faster processing speeds for thick and irregular slabs, delivering precise cuts without heat damage while maintaining high material integrity. Laser-cut marble excels in detailed, intricate designs on thinner slabs but operates at slower speeds due to the need for gradual slicing and cooling periods. Choosing between waterjet and laser cutting depends on project complexity, with waterjet preferred for efficiency in heavy-duty tasks and laser for fine, delicate patterns.

Cost Analysis: Waterjet Cutting vs. Laser Cutting

Waterjet cutting marble typically incurs higher operational costs due to abrasive materials and slower cutting speeds, whereas laser cutting offers more cost-efficient processing with less material waste but may have limitations with thicker marble slabs. Waterjet machines demand significant maintenance and consumables, increasing long-term expenses, while laser cutting systems prioritize precision and speed, reducing labor costs and improving throughput. For large-scale or intricate marble designs, the choice between waterjet and laser cutting hinges on balancing initial equipment investment against ongoing operational savings.

Applications and Ideal Use Cases

Waterjet marble cutting excels in intricate designs and thick slab processing, making it ideal for custom countertops, decorative inlays, and complex architectural elements. Laser-cut marble offers high precision for fine detailing and smooth edges, suitable for delicate engraving, intricate patterns, and signage applications. Both methods serve unique purposes: waterjet for robust, multi-dimensional cuts and laser for precision and fine artistry in marble crafting.

Choosing the Right Cutting Method for Your Marble Project

Waterjet marble cutting offers exceptional precision and preserves the stone's natural integrity by using high-pressure water mixed with abrasive materials, making it ideal for intricate designs and thick slabs. Laser-cut marble, while highly accurate for detailed patterns, may cause slight surface discoloration or thermal stress, thus better suited for thinner pieces and decorative applications. Selecting the right method depends on the project's complexity, marble thickness, and desired finish, with waterjet cutting preferred for durability and versatility, and laser cutting chosen for delicate, fine detailing.

Waterjet marble vs laser-cut marble Infographic

materialdif.com

materialdif.com