Rawhide is untreated animal hide that is stiff and porous, making it less durable but safe for pets to chew on as it softens over time. Tanned hide undergoes a chemical process to enhance durability, color, and texture, resulting in a more flexible and long-lasting material often used for premium leather pet accessories. Choosing between rawhide and tanned hide depends on the pet's chewing habits and the intended use, with rawhide favored for chew toys and tanned leather preferred for collars and leashes.

Table of Comparison

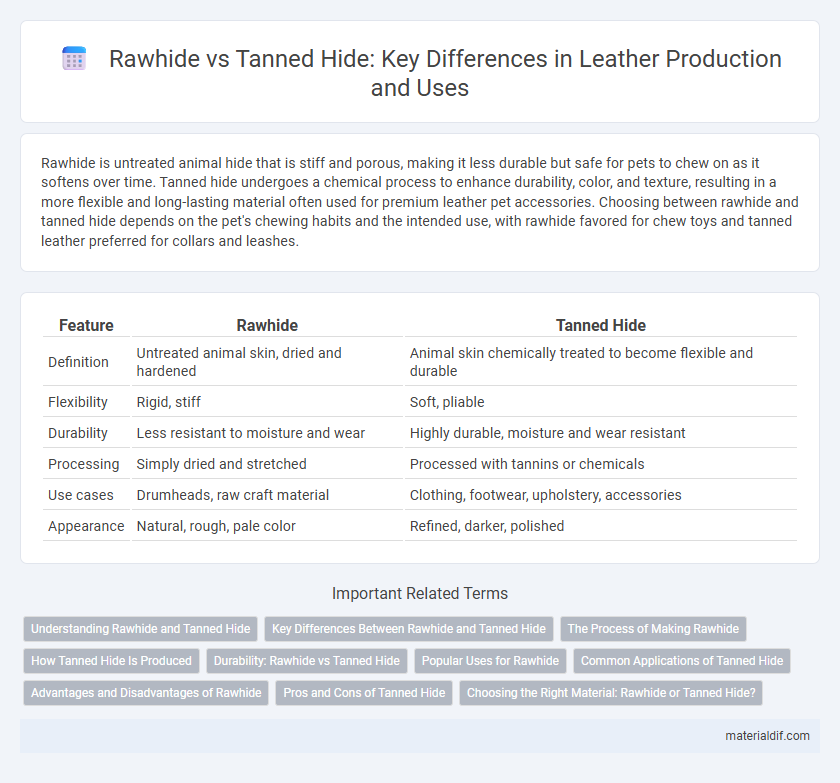

| Feature | Rawhide | Tanned Hide |

|---|---|---|

| Definition | Untreated animal skin, dried and hardened | Animal skin chemically treated to become flexible and durable |

| Flexibility | Rigid, stiff | Soft, pliable |

| Durability | Less resistant to moisture and wear | Highly durable, moisture and wear resistant |

| Processing | Simply dried and stretched | Processed with tannins or chemicals |

| Use cases | Drumheads, raw craft material | Clothing, footwear, upholstery, accessories |

| Appearance | Natural, rough, pale color | Refined, darker, polished |

Understanding Rawhide and Tanned Hide

Rawhide is the untreated skin of an animal, typically dried and hardened without undergoing tanning, resulting in a stiff and porous material. Tanned hide undergoes a chemical process called tanning, which stabilizes the collagen fibers, making the leather more durable, flexible, and resistant to moisture. Understanding the differences between rawhide and tanned hide is essential for selecting the appropriate material in applications ranging from crafts and tooling to footwear and upholstery.

Key Differences Between Rawhide and Tanned Hide

Rawhide is untreated animal hide that retains its natural stiffness and hardness after drying, while tanned hide undergoes a chemical process using tannins or chromium salts to become soft, durable, and resistant to decomposition. Rawhide is commonly used for drum heads, laces, and chewed dog toys due to its rigidity, whereas tanned leather is preferred for garments, upholstery, and accessories because of its flexibility and enhanced longevity. The tanning process stabilizes collagen fibers, preventing rawhide's susceptibility to water damage and microbial decay.

The Process of Making Rawhide

Rawhide is produced by removing the hair and flesh from animal hides, followed by a drying process without chemical tanning, which preserves the natural toughness and rigidity of the material. Unlike tanned hide, rawhide hardens as it dries, making it suitable for products requiring structural durability such as drum heads and dog chews. The absence of tanning agents means rawhide remains biodegradable but less flexible and water-resistant compared to tanned leather.

How Tanned Hide Is Produced

Tanned hide is produced through a chemical process called tanning, which stabilizes the rawhide by converting its collagen fibers into a durable, non-decomposable material. This process involves soaking the rawhide in tannins derived from plant extracts, chromium salts, or other tanning agents that prevent decay and enhance flexibility. The result is leather that is more resistant to water, heat, and wear compared to untreated rawhide.

Durability: Rawhide vs Tanned Hide

Rawhide is less durable than tanned hide due to its untreated fiber structure, making it prone to stiffness and cracking when exposed to moisture. Tanned hide undergoes chemical processing that enhances flexibility, resistance to wear, and longevity, which significantly improves its durability for various applications. Unlike rawhide, tanned leather maintains structural integrity under environmental stress, ensuring better performance in long-term use.

Popular Uses for Rawhide

Rawhide, known for its stiffness and durability, is commonly used in drumheads, dog chews, and traditional crafts such as drum making and moccasin construction. Its untreated, untanned state allows it to harden significantly when dried, making it ideal for protective coverings and sturdy, rustic applications. Rawhide's ability to absorb moisture and then tighten ensures a firm, resilient material favored in both functional and decorative contexts.

Common Applications of Tanned Hide

Tanned hide is commonly used in the production of high-quality leather goods such as shoes, belts, wallets, and upholstery due to its enhanced durability, flexibility, and resistance to moisture. Unlike rawhide, which remains stiff and brittle, tanned hide undergoes chemical treatment processes like vegetable or chrome tanning that transform it into a soft, pliable material suitable for garments and accessories. The extensive applications of tanned hide in fashion, furniture, and automotive industries highlight its versatility and superior performance in everyday use.

Advantages and Disadvantages of Rawhide

Rawhide, made from untanned animal skins, offers superior stiffness and durability compared to tanned hide, making it ideal for crafting items like drum heads and rugged tools. Its main disadvantage lies in its susceptibility to moisture, which can cause it to become brittle or deformed, limiting its use in wet environments. Unlike tanned hide, rawhide lacks flexibility and water resistance, reducing comfort for apparel and accessories.

Pros and Cons of Tanned Hide

Tanned hide offers enhanced durability, flexibility, and resistance to moisture compared to rawhide, making it ideal for crafting long-lasting leather products like shoes, bags, and upholstery. The tanning process stabilizes the collagen fibers, preventing decomposition and allowing for various finishes and colors, but it involves chemical treatments that can impact environmental sustainability. Despite the benefits, tanned hides may be less rigid and have reduced natural breathability compared to rawhide, which limits their use in certain traditional applications.

Choosing the Right Material: Rawhide or Tanned Hide?

Choosing between rawhide and tanned hide depends on the intended application and desired durability. Rawhide, untreated and stiff, is ideal for crafting items like drumheads or traditional decor, offering rigidity and a natural finish. Tanned hide undergoes chemical processing, enhancing flexibility, water resistance, and longevity, making it suitable for clothing, upholstery, and durable leather goods.

Rawhide vs Tanned Hide Infographic

materialdif.com

materialdif.com