Water-based finishing on leather offers a more environmentally friendly option with lower volatile organic compounds (VOCs) emissions, resulting in safer indoor air quality and reduced health risks for workers. Solvent-based finishing provides superior durability and a richer appearance due to stronger binding agents but poses higher environmental and health hazards because of toxic solvents. Choosing between these finishes depends on balancing eco-conscious priorities with desired leather performance and aesthetic qualities.

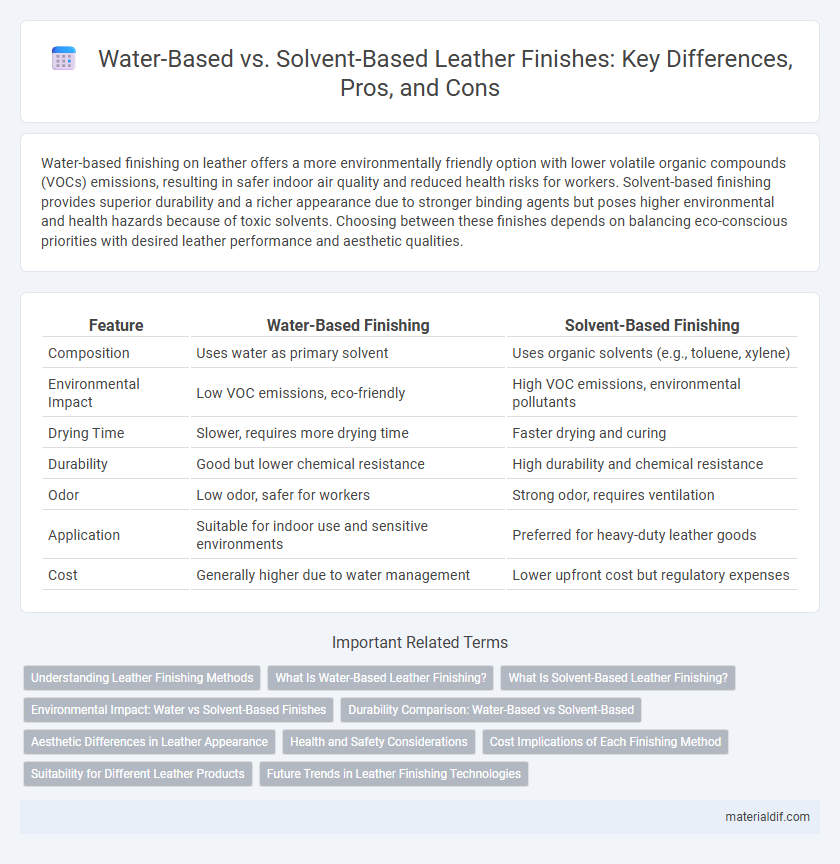

Table of Comparison

| Feature | Water-Based Finishing | Solvent-Based Finishing |

|---|---|---|

| Composition | Uses water as primary solvent | Uses organic solvents (e.g., toluene, xylene) |

| Environmental Impact | Low VOC emissions, eco-friendly | High VOC emissions, environmental pollutants |

| Drying Time | Slower, requires more drying time | Faster drying and curing |

| Durability | Good but lower chemical resistance | High durability and chemical resistance |

| Odor | Low odor, safer for workers | Strong odor, requires ventilation |

| Application | Suitable for indoor use and sensitive environments | Preferred for heavy-duty leather goods |

| Cost | Generally higher due to water management | Lower upfront cost but regulatory expenses |

Understanding Leather Finishing Methods

Water-based finishing utilizes environmentally friendly solvents derived from water, reducing VOC emissions and enhancing leather's breathability and flexibility, while solvent-based finishing relies on chemical solvents that create a more durable, water-resistant surface but can compromise leather's natural softness. Understanding leather finishing methods highlights the trade-off between sustainability and performance, with water-based finishes offering eco-conscious benefits and solvent-based finishes providing superior protection and longevity. Selecting the appropriate finishing method depends on desired leather characteristics such as texture, durability, and environmental impact.

What Is Water-Based Leather Finishing?

Water-based leather finishing uses environmentally friendly water as the primary solvent, reducing harmful emissions and toxicity compared to traditional solvent-based methods. This technique enhances leather's durability, flexibility, and appearance while offering lower VOC (volatile organic compound) content, making it a safer choice for both workers and consumers. Common in high-quality leather goods, water-based finishes provide excellent resistance to cracking and fading without compromising the leather's natural breathability.

What Is Solvent-Based Leather Finishing?

Solvent-based leather finishing involves using chemical solvents to dissolve and apply dyes, pigments, and protective coatings, resulting in a durable and glossy surface. This method enhances the leather's resistance to water, stains, and wear by forming a resilient film that penetrates deeply into the material. Compared to water-based finishes, solvent-based finishes typically provide stronger adhesion and a higher level of color richness, making them ideal for high-end leather products.

Environmental Impact: Water vs Solvent-Based Finishes

Water-based leather finishes significantly reduce volatile organic compound (VOC) emissions, lowering air pollution and health risks compared to solvent-based finishes, which release high levels of harmful VOCs during application and drying. The reduced toxicity of water-based finishes leads to safer disposal and less environmental contamination, preserving soil and water quality. Manufacturers increasingly prefer water-based solutions to comply with stringent environmental regulations and promote sustainable leather production.

Durability Comparison: Water-Based vs Solvent-Based

Water-based finishing offers enhanced resistance to cracking and yellowing over time, making it ideal for maintaining leather's natural aesthetics and flexibility. Solvent-based finishes, while providing a tougher, more chemical-resistant surface, can lead to faster wear under repeated bending and exposure to harsh conditions. Durability comparison highlights water-based finishes as more environmentally friendly with sustained performance, whereas solvent-based finishes excel in applications requiring heavy-duty protection.

Aesthetic Differences in Leather Appearance

Water-based finishing on leather enhances color vibrancy and provides a natural, matte appearance, preserving the grain's subtle texture. Solvent-based finishing offers a glossier, more uniform surface with enhanced durability but may mask fine details in the leather's grain. The choice impacts the leather's sheen, color depth, and tactile perception, influencing its visual appeal and suitability for different applications.

Health and Safety Considerations

Water-based leather finishing reduces exposure to volatile organic compounds (VOCs), significantly lowering health risks such as respiratory irritation and long-term chronic conditions compared to solvent-based finishes. Solvent-based finishing involves flammable and toxic chemicals requiring stringent ventilation and safety protocols to prevent fire hazards and chemical inhalation. Choosing water-based finishes supports safer workplaces and complies with increasingly strict environmental and occupational safety regulations.

Cost Implications of Each Finishing Method

Water-based finishing for leather generally incurs higher upfront costs due to the need for specialized equipment and longer drying times, but offers savings in waste disposal and regulatory compliance. Solvent-based finishing often has lower initial expenses yet can lead to increased costs over time from volatile organic compound (VOC) emissions management, health hazards, and stricter environmental regulations. Considering total cost of ownership, water-based finishing presents a more sustainable and potentially cost-effective solution in large-scale leather production.

Suitability for Different Leather Products

Water-based finishing offers enhanced environmental benefits and is ideal for soft, flexible leather products like garment leather and upholstery, allowing better breathability and maintaining natural texture. Solvent-based finishing provides superior durability and chemical resistance, making it suitable for heavy-duty leather goods such as footwear, belts, and industrial leather applications. Choosing the appropriate finishing depends on the leather product's intended use, required durability, and environmental considerations.

Future Trends in Leather Finishing Technologies

Water-based finishing in leather offers eco-friendly advantages and reduced volatile organic compound (VOC) emissions, driving industry adoption. Solvent-based finishing remains valued for durability and enhanced surface texture but faces stricter environmental regulations. Future trends prioritize sustainable, bio-based finishes and advanced nanotechnology coatings to improve performance while minimizing environmental impact in leather finishing.

Water-Based Finishing vs Solvent-Based Finishing Infographic

materialdif.com

materialdif.com