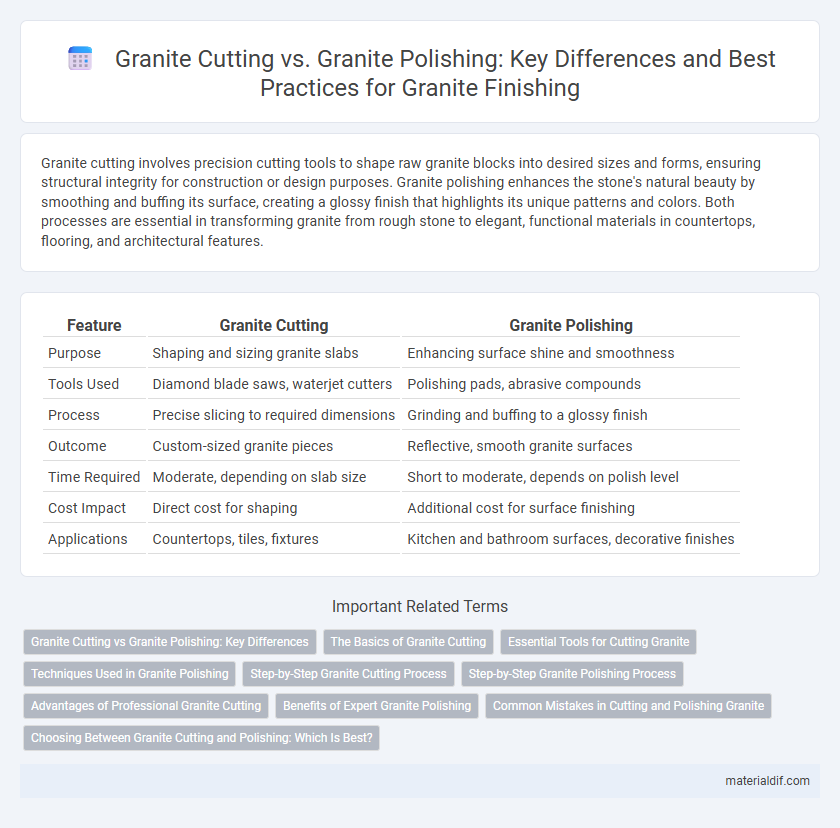

Granite cutting involves precision cutting tools to shape raw granite blocks into desired sizes and forms, ensuring structural integrity for construction or design purposes. Granite polishing enhances the stone's natural beauty by smoothing and buffing its surface, creating a glossy finish that highlights its unique patterns and colors. Both processes are essential in transforming granite from rough stone to elegant, functional materials in countertops, flooring, and architectural features.

Table of Comparison

| Feature | Granite Cutting | Granite Polishing |

|---|---|---|

| Purpose | Shaping and sizing granite slabs | Enhancing surface shine and smoothness |

| Tools Used | Diamond blade saws, waterjet cutters | Polishing pads, abrasive compounds |

| Process | Precise slicing to required dimensions | Grinding and buffing to a glossy finish |

| Outcome | Custom-sized granite pieces | Reflective, smooth granite surfaces |

| Time Required | Moderate, depending on slab size | Short to moderate, depends on polish level |

| Cost Impact | Direct cost for shaping | Additional cost for surface finishing |

| Applications | Countertops, tiles, fixtures | Kitchen and bathroom surfaces, decorative finishes |

Granite Cutting vs Granite Polishing: Key Differences

Granite cutting involves precise shaping and sizing of raw granite slabs using diamond-tipped saws and advanced CNC machines to create custom dimensions for countertops, tiles, or monuments. Granite polishing, on the other hand, enhances the stone's aesthetic appeal by smoothing its surface with progressively finer abrasives, resulting in a glossy, reflective finish that highlights the natural patterns and colors. While cutting focuses on structural modification and form, polishing emphasizes surface texture and visual enhancement.

The Basics of Granite Cutting

Granite cutting involves using diamond-tipped blades or water jets to precisely shape and size granite blocks into slabs or specific designs, ensuring minimal waste and accurate dimensions. The process requires specialized equipment and skilled technicians to maintain the structural integrity of the stone while achieving smooth, straight edges. Proper cutting lays the foundation for subsequent polishing, which enhances the granite's natural beauty and surface smoothness.

Essential Tools for Cutting Granite

Granite cutting requires specialized diamond-tipped blades and wet saws to ensure precise, clean cuts without fracturing the stone. Essential tools include angle grinders equipped with diamond blades, bridge saws, and water-cooled cutting systems that reduce heat and prevent dust. Proper cutting tools maintain granite's structural integrity while allowing for custom shapes and sizes before polishing.

Techniques Used in Granite Polishing

Granite polishing involves advanced techniques such as diamond abrasive pads progressively moving from coarse to fine grits to achieve a high-gloss surface. Water is used to cool the stone and reduce dust during the polishing process, while specialized polishing compounds enhance the shine and bring out the natural color of the granite. Unlike cutting, which uses diamond blades for shaping, polishing emphasizes surface refinement to highlight granite's intricate patterns and textures.

Step-by-Step Granite Cutting Process

Granite cutting involves precise steps starting with selecting the right diamond-tipped blade to score the stone, followed by controlled sawing to shape the granite slab accurately. After the rough cuts, the edges are refined using grinders and routers to achieve the desired dimensions and smoothness. This cutting process contrasts with granite polishing, which focuses on enhancing the surface's shine and texture rather than altering its shape.

Step-by-Step Granite Polishing Process

Granite polishing involves a precise step-by-step process that enhances the stone's natural shine and durability by progressively smoothing the surface with finer abrasives, starting from coarse grinding to remove imperfections. The process includes wet sanding with diamond pads of varying grits, polishing with specialized compounds, and sealing to protect the granite from stains and wear. This meticulous method contrasts with granite cutting, which focuses primarily on shaping and sizing the stone using diamond-tipped saw blades without altering its surface finish.

Advantages of Professional Granite Cutting

Professional granite cutting ensures precise dimensions and smooth edges, enhancing the structural integrity and aesthetic appeal of countertops and architectural elements. Skilled cutters use advanced tools and techniques to minimize material waste and reduce the risk of cracks or chips during the cutting process. This precision results in a perfect fit for installations, saving time and cost compared to DIY methods or less experienced handling.

Benefits of Expert Granite Polishing

Expert granite polishing enhances the stone's natural shine and depth, bringing out intricate mineral patterns and vibrant colors that cutting alone cannot reveal. Polishing also creates a smooth, glossy surface which increases resistance to stains, moisture, and scratches, significantly extending the countertop's lifespan. By refining the texture and sealing the pores, professional polishing reduces maintenance needs and preserves the granite's structural integrity over time.

Common Mistakes in Cutting and Polishing Granite

Common mistakes in granite cutting include using dull blades, which cause rough edges and cracks, and improper measuring that leads to inaccurate cuts and wasted material. During granite polishing, over-polishing can result in uneven surfaces and loss of natural texture, while under-polishing leaves a dull finish prone to staining. Ensuring precision in cutting with diamond-tipped tools and following manufacturer guidelines for polishing compounds avoids damage and maintains granite's natural beauty.

Choosing Between Granite Cutting and Polishing: Which Is Best?

Granite cutting involves shaping and resizing slabs to fit specific dimensions, essential for customized installations and precise edges, while granite polishing enhances the stone's surface by removing scratches and achieving a glossy finish that highlights its natural patterns. Choosing between granite cutting and polishing depends on whether the priority is structural modification or aesthetic enhancement, with cutting necessary for adjustments and polishing ideal for restoring or improving surface appearance. For durable, visually striking countertops, combining precise granite cutting with expert polishing ensures optimal functionality and elegance.

Granite Cutting vs Granite Polishing Infographic

materialdif.com

materialdif.com