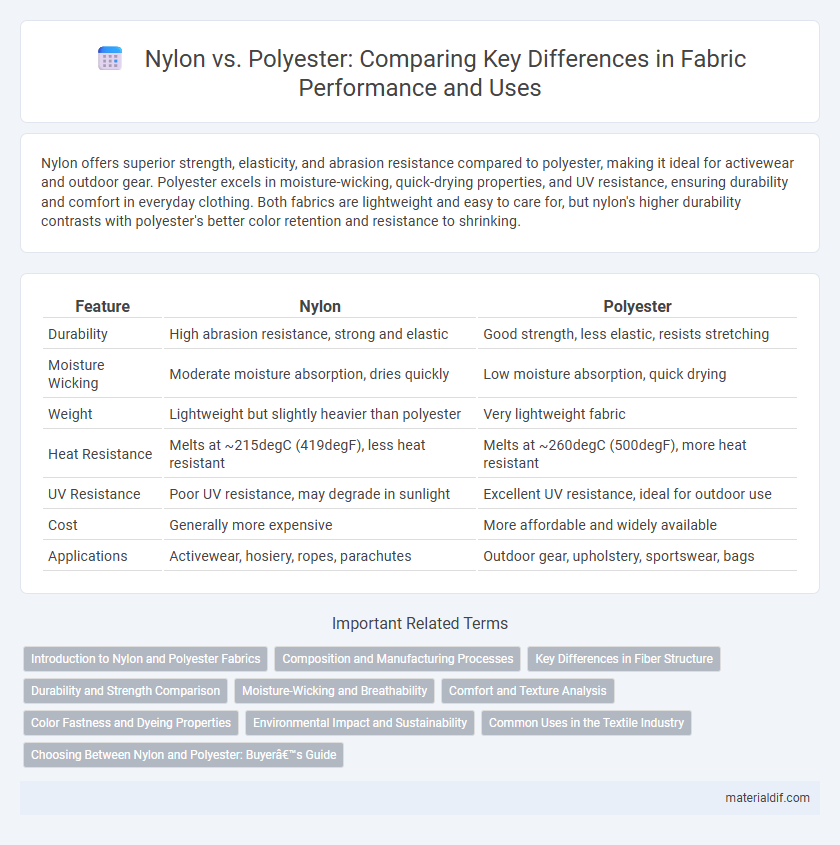

Nylon offers superior strength, elasticity, and abrasion resistance compared to polyester, making it ideal for activewear and outdoor gear. Polyester excels in moisture-wicking, quick-drying properties, and UV resistance, ensuring durability and comfort in everyday clothing. Both fabrics are lightweight and easy to care for, but nylon's higher durability contrasts with polyester's better color retention and resistance to shrinking.

Table of Comparison

| Feature | Nylon | Polyester |

|---|---|---|

| Durability | High abrasion resistance, strong and elastic | Good strength, less elastic, resists stretching |

| Moisture Wicking | Moderate moisture absorption, dries quickly | Low moisture absorption, quick drying |

| Weight | Lightweight but slightly heavier than polyester | Very lightweight fabric |

| Heat Resistance | Melts at ~215degC (419degF), less heat resistant | Melts at ~260degC (500degF), more heat resistant |

| UV Resistance | Poor UV resistance, may degrade in sunlight | Excellent UV resistance, ideal for outdoor use |

| Cost | Generally more expensive | More affordable and widely available |

| Applications | Activewear, hosiery, ropes, parachutes | Outdoor gear, upholstery, sportswear, bags |

Introduction to Nylon and Polyester Fabrics

Nylon, a synthetic polymer developed in the 1930s, is renowned for its exceptional strength, elasticity, and abrasion resistance, making it ideal for activewear and outdoor gear. Polyester, created from petrochemical products, is highly valued for its durability, wrinkle resistance, and quick-drying properties, commonly used in apparel and home textiles. Both fabrics dominate the textile industry, offering versatile performance characteristics suited to different end-use applications.

Composition and Manufacturing Processes

Nylon is a synthetic polymer made from polyamides through a process called condensation polymerization, producing strong, elastic fibers with high durability. Polyester, primarily composed of polyethylene terephthalate (PET), is manufactured using a polycondensation reaction between ethylene glycol and terephthalic acid, resulting in fibers known for excellent resistance to shrinking and stretching. Both fabrics offer resilience and moisture resistance, but nylon's production involves petroleum-based chemicals that yield a more elastic material, while polyester's manufacturing emphasizes energy efficiency and recyclability.

Key Differences in Fiber Structure

Nylon fibers are formed from polyamides with a crystalline molecular structure that provides high strength, elasticity, and abrasion resistance. Polyester fibers consist of polyethylene terephthalate (PET) with a semi-crystalline structure, offering excellent durability, moisture resistance, and quick-drying properties. The key difference lies in nylon's superior flexibility and resilience compared to polyester's greater resistance to UV degradation and chemical exposure.

Durability and Strength Comparison

Nylon exhibits superior tensile strength and exceptional abrasion resistance, making it highly durable for heavy-duty applications. Polyester offers good durability with high resistance to UV degradation and moisture, maintaining performance in outdoor environments. Both fibers provide strong wear resistance, but nylon generally outperforms polyester in overall strength and longevity in rigorous use.

Moisture-Wicking and Breathability

Nylon fabric offers excellent moisture-wicking properties by efficiently drawing sweat away from the skin, making it ideal for high-intensity activities. Polyester also provides strong moisture-wicking capabilities but excels in breathability due to its lightweight and porous structure, promoting faster evaporation of moisture. Choosing between nylon and polyester depends on the specific balance needed between durability, moisture management, and airflow in performance wear.

Comfort and Texture Analysis

Nylon fabric offers superior smoothness and lightweight softness, making it highly comfortable for garments worn close to the skin, while its excellent elasticity enhances flexibility and fit. Polyester tends to be coarser with a slightly rougher texture but excels in moisture-wicking and durability, often preferred for activewear that requires resilience and breathability. The choice between nylon and polyester depends on comfort priorities: nylon provides a silkier feel and stretch, whereas polyester delivers enhanced moisture management and toughness.

Color Fastness and Dyeing Properties

Nylon exhibits superior dye affinity and vibrant color fastness due to its polyamide structure, allowing deep penetration of dyes and resistance to fading. Polyester, made from polyethylene terephthalate, requires disperse dyes and generally has lower dye uptake, which can limit color vibrancy but offers excellent resistance to washing and sunlight exposure. Both fibers present different challenges and advantages in dyeing processes, making Nylon preferable for vivid, long-lasting colors and Polyester better suited for durability in color retention.

Environmental Impact and Sustainability

Nylon production relies on petrochemicals, resulting in higher greenhouse gas emissions and non-biodegradable waste compared to polyester, which can be partially derived from recycled plastics like PET bottles. Polyester's widespread recyclability and lower energy consumption in manufacturing enhance its sustainability profile, while nylon's slower degradation poses long-term environmental challenges. Choosing recycled polyester fabrics supports circular fashion initiatives by reducing virgin resource extraction and landfill accumulation.

Common Uses in the Textile Industry

Nylon is widely used in activewear, hosiery, and lingerie due to its exceptional elasticity and abrasion resistance, making it ideal for garments requiring stretch and durability. Polyester dominates in outdoor apparel, home furnishings, and upholstery because of its moisture-wicking properties, resistance to wrinkles, and quick-drying capabilities. Both fibers are integral to the textile industry, with nylon favored for performance wear and polyester preferred for versatility and cost-efficiency.

Choosing Between Nylon and Polyester: Buyer’s Guide

Nylon offers superior strength, elasticity, and abrasion resistance, making it ideal for durable, high-performance fabrics used in sportswear and outdoor gear. Polyester excels in moisture-wicking, quick-drying properties, and UV resistance, providing excellent breathability and color retention for everyday apparel and activewear. Selecting between nylon and polyester depends on required fabric durability, moisture management, and cost efficiency for specific applications.

Nylon vs Polyester Infographic

materialdif.com

materialdif.com