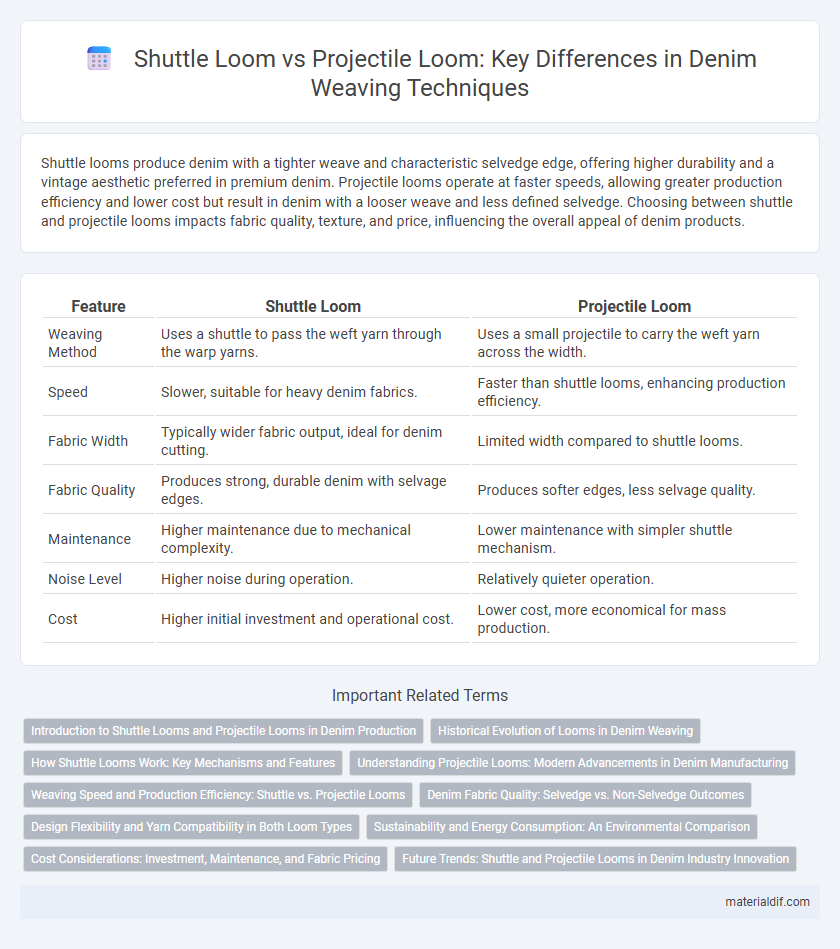

Shuttle looms produce denim with a tighter weave and characteristic selvedge edge, offering higher durability and a vintage aesthetic preferred in premium denim. Projectile looms operate at faster speeds, allowing greater production efficiency and lower cost but result in denim with a looser weave and less defined selvedge. Choosing between shuttle and projectile looms impacts fabric quality, texture, and price, influencing the overall appeal of denim products.

Table of Comparison

| Feature | Shuttle Loom | Projectile Loom |

|---|---|---|

| Weaving Method | Uses a shuttle to pass the weft yarn through the warp yarns. | Uses a small projectile to carry the weft yarn across the width. |

| Speed | Slower, suitable for heavy denim fabrics. | Faster than shuttle looms, enhancing production efficiency. |

| Fabric Width | Typically wider fabric output, ideal for denim cutting. | Limited width compared to shuttle looms. |

| Fabric Quality | Produces strong, durable denim with selvage edges. | Produces softer edges, less selvage quality. |

| Maintenance | Higher maintenance due to mechanical complexity. | Lower maintenance with simpler shuttle mechanism. |

| Noise Level | Higher noise during operation. | Relatively quieter operation. |

| Cost | Higher initial investment and operational cost. | Lower cost, more economical for mass production. |

Introduction to Shuttle Looms and Projectile Looms in Denim Production

Shuttle looms, traditionally used in denim production, operate by carrying a weft yarn through the warp yarns using a shuttle, creating tightly woven, selvedge denim known for its durability and premium quality. Projectile looms utilize a small projectile to propel the weft yarn across the warp, allowing higher speeds and efficiency while maintaining fabric strength suitable for denim manufacturing. Both loom types influence the texture and finish of denim, with shuttle looms favored for classic selvedge denim and projectile looms commonly employed in large-scale production.

Historical Evolution of Looms in Denim Weaving

Shuttle looms, integral to early denim weaving since the late 19th century, produced tightly woven, durable denim fabric with a distinctive selvedge edge prized for quality and longevity. Projectile looms emerged mid-20th century, increasing production speed and efficiency by using a small projectile to carry the weft yarn, yet often sacrificing the characteristic selvedge finish found in shuttle-woven denim. The evolution from shuttle to projectile looms reflects industrial advancements balancing fabric durability and production scale in the denim industry.

How Shuttle Looms Work: Key Mechanisms and Features

Shuttle looms operate by carrying a bobbin of weft yarn back and forth through the warp threads, utilizing a shuttle that moves across a closed shed to weave fabric. This mechanism enables the production of tightly woven, durable denim with selvage edges, which are highly valued for their strength and clean finish. The slower weaving speed compared to projectile looms results in a denser fabric structure, making shuttle looms ideal for premium denim manufacturing.

Understanding Projectile Looms: Modern Advancements in Denim Manufacturing

Projectile looms utilize a high-speed projectile to carry the weft yarn across the warp, enabling faster and more efficient denim production compared to traditional shuttle looms. Modern advancements in projectile loom technology include improved tension control, reduced yarn breakage, and enhanced fabric uniformity, resulting in higher quality denim with consistent texture. These innovations support large-scale manufacturing by increasing production speed while maintaining the durability and aesthetic appeal critical to denim garments.

Weaving Speed and Production Efficiency: Shuttle vs. Projectile Looms

Projectile looms operate at significantly higher weaving speeds than shuttle looms, achieving rates up to 400 picks per minute compared to shuttle looms' 100-120 picks per minute, which enhances production efficiency for denim fabric. The continuous, high-speed operation of projectile looms reduces downtime and increases output volume while maintaining fabric quality. Though shuttle looms offer traditional selvage edges prized in premium denim, projectile looms dominate mass production due to their faster and more cost-effective weaving capabilities.

Denim Fabric Quality: Selvedge vs. Non-Selvedge Outcomes

Shuttle looms produce denim with a tightly woven selvedge edge, known for superior durability, richer texture, and clean finish, making it highly sought after in premium denim markets. Projectile looms enable faster production of non-selvedge denim, which often exhibits a wider, less refined edge and slightly lower fabric density, affecting overall garment strength and fade characteristics. The choice between shuttle and projectile weaving significantly impacts denim quality, with selvedge denim prized for its craftsmanship and longevity, while non-selvedge denim offers cost efficiency and mass-market appeal.

Design Flexibility and Yarn Compatibility in Both Loom Types

Shuttle looms offer superior design flexibility by enabling intricate patterns and varied fabric textures due to their ability to work with a wide range of yarn types, including delicate and specialty yarns. Projectile looms provide higher speed and efficiency but have limitations in handling very fine or highly elastic yarns, restricting the diversity of fabric designs. Selecting between shuttle and projectile looms depends on the desired denim aesthetic and the specific yarn properties required for the final textile quality.

Sustainability and Energy Consumption: An Environmental Comparison

Shuttle looms exhibit higher energy consumption due to slower weaving speeds and increased friction, leading to greater carbon emissions compared to projectile looms. Projectile looms, designed for efficiency, consume less electricity and reduce waste, contributing to lower environmental impact in denim production. Sustainable denim manufacturing increasingly favors projectile looms to meet eco-friendly standards and decrease the industry's overall carbon footprint.

Cost Considerations: Investment, Maintenance, and Fabric Pricing

Shuttle looms require higher initial investment and incur increased maintenance costs due to their complex mechanical parts compared to projectile looms. Maintenance expenses for shuttle looms stem from frequent repairs of shuttles and shuttle boxes, while projectile looms demand less costly upkeep with more modern components. Fabric pricing from shuttle loom production tends to be higher, reflecting the slower weaving speed and increased labor, whereas projectile loom fabrics are more cost-effective due to faster production rates and lower operational expenses.

Future Trends: Shuttle and Projectile Looms in Denim Industry Innovation

Shuttle looms, known for their ability to produce selvage denim with a traditional, high-quality finish, are gradually being complemented by projectile looms that offer higher speed and efficiency, making them suitable for mass production. Future trends in denim manufacturing emphasize integrating advanced automation and smart technology into both shuttle and projectile looms to enhance precision, reduce waste, and boost fabric consistency. Innovations in loom design focus on sustainability by optimizing energy consumption and enabling the use of eco-friendly fibers, driving the denim industry toward greener production methods.

Shuttle Loom vs Projectile Loom Infographic

materialdif.com

materialdif.com