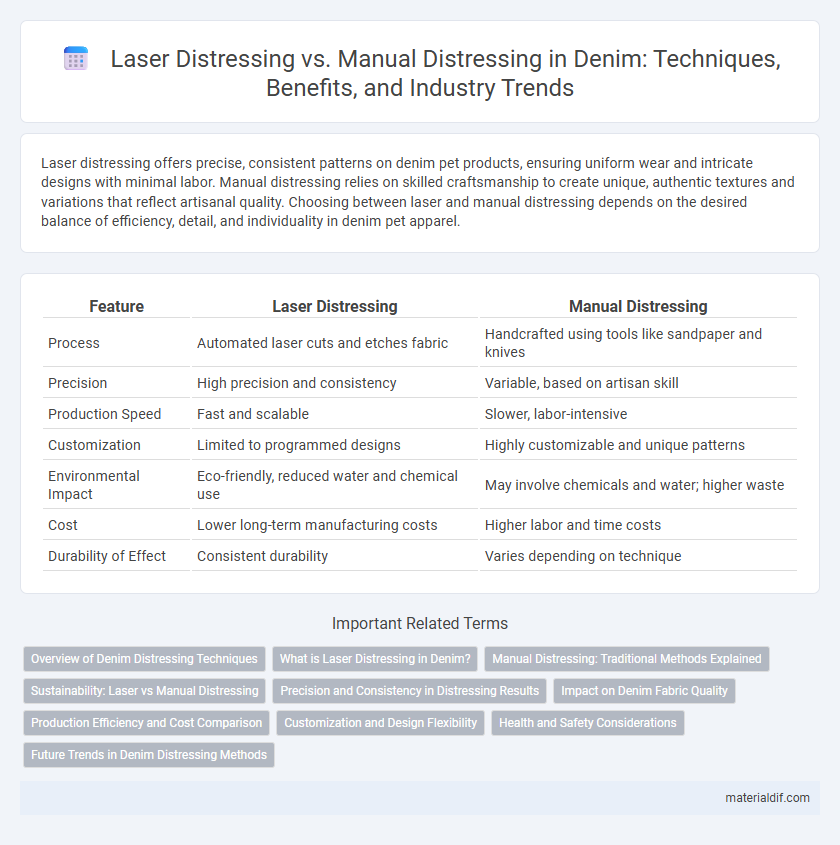

Laser distressing offers precise, consistent patterns on denim pet products, ensuring uniform wear and intricate designs with minimal labor. Manual distressing relies on skilled craftsmanship to create unique, authentic textures and variations that reflect artisanal quality. Choosing between laser and manual distressing depends on the desired balance of efficiency, detail, and individuality in denim pet apparel.

Table of Comparison

| Feature | Laser Distressing | Manual Distressing |

|---|---|---|

| Process | Automated laser cuts and etches fabric | Handcrafted using tools like sandpaper and knives |

| Precision | High precision and consistency | Variable, based on artisan skill |

| Production Speed | Fast and scalable | Slower, labor-intensive |

| Customization | Limited to programmed designs | Highly customizable and unique patterns |

| Environmental Impact | Eco-friendly, reduced water and chemical use | May involve chemicals and water; higher waste |

| Cost | Lower long-term manufacturing costs | Higher labor and time costs |

| Durability of Effect | Consistent durability | Varies depending on technique |

Overview of Denim Distressing Techniques

Laser distressing in denim employs precise technology to create consistent, intricate patterns with minimal environmental impact, enhancing production speed and repeatability. Manual distressing involves hand techniques like sanding, ripping, and scraping, offering unique, artisanal textures with varied wear patterns that technology struggles to replicate. Combining laser and manual methods allows manufacturers to balance efficiency and craftsmanship, meeting diverse consumer preferences in denim aesthetics.

What is Laser Distressing in Denim?

Laser distressing in denim uses precise laser technology to create worn or faded effects on fabric surfaces, offering consistent and customizable patterns without physical abrasion. Unlike manual distressing, which involves hand tools like sandpaper or knives, laser distressing reduces production time and environmental impact by minimizing water and chemical usage. This innovative method enables designers to achieve intricate designs and unique textures sustainably and efficiently.

Manual Distressing: Traditional Methods Explained

Manual distressing in denim involves skilled artisans using tools like sandpaper, pumice stones, and knives to create authentic wear patterns and vintage effects. This traditional technique allows for precise control over fabric texture and fading, resulting in unique, handcrafted jeans with natural-looking imperfections. Compared to laser distressing, manual methods contribute to a higher level of craftsmanship and individuality in each denim piece.

Sustainability: Laser vs Manual Distressing

Laser distressing reduces water and chemical usage by precisely etching patterns onto denim, offering a more sustainable alternative to manual distressing methods that typically consume large amounts of water and harsh chemicals. This technology minimizes waste and energy consumption, aligning with eco-friendly production goals in the denim industry. Manual distressing, while traditional, often results in inconsistent outcomes and significantly higher environmental impact due to extensive resource use.

Precision and Consistency in Distressing Results

Laser distressing offers superior precision and consistency in denim finishing by utilizing advanced technology to create uniform patterns and controlled fading, minimizing human error. Manual distressing relies heavily on artisan skill, resulting in unique but often variable outcomes that can differ significantly between batches. Brands seeking scalable production with exact replication favor laser techniques, while those prioritizing authentic, handcrafted appeal may opt for manual methods despite potential inconsistencies.

Impact on Denim Fabric Quality

Laser distressing on denim fabric offers precise and consistent wear patterns, reducing physical damage and preserving fabric integrity compared to manual distressing methods. Manual distressing involves abrasive techniques like sanding, scraping, or chemical treatments, which can weaken fibers and lead to uneven wear and reduced durability. The controlled nature of laser distressing enhances denim quality by minimizing fiber breakage and maintaining tensile strength, thereby extending garment lifespan.

Production Efficiency and Cost Comparison

Laser distressing in denim production offers significantly higher efficiency by automating intricate designs within seconds, reducing labor costs and minimizing fabric waste. Manual distressing relies heavily on skilled artisans, increasing production time and labor expenses while introducing variability in design precision. Cost comparison favors laser distressing for large-scale manufacturing due to its speed, consistency, and lower operational expenses despite higher initial equipment investment.

Customization and Design Flexibility

Laser distressing offers precise customization and intricate design flexibility by using controlled beams to create consistent patterns on denim, enabling detailed and repeatable effects that manual methods cannot easily achieve. Manual distressing allows artisans to create unique, one-of-a-kind textures and imperfections, adding authentic character and variation to each piece of denim. The choice between laser and manual distressing depends on whether uniform design control or individualized, handcrafted aesthetics are prioritized in denim customization.

Health and Safety Considerations

Laser distressing in denim manufacturing significantly reduces workers' exposure to harmful dust and chemicals commonly associated with manual sanding techniques. Manual distressing increases the risk of respiratory issues due to airborne particles and requires extensive use of protective gear, whereas laser technology minimizes airborne contaminants and enhances workplace safety. Evaluating the shift towards laser distressing highlights a key move in reducing occupational hazards in denim production environments.

Future Trends in Denim Distressing Methods

Laser distressing in denim production offers precision and consistency while reducing environmental impact through less water and chemical use. Manual distressing, though labor-intensive and less uniform, provides unique, artisanal details favored by niche markets. Future trends indicate a shift towards hybrid techniques combining laser technology with hand finishing to balance efficiency and craftsmanship in sustainable denim manufacturing.

Laser Distressing vs Manual Distressing Infographic

materialdif.com

materialdif.com