Combed cotton undergoes a refined process that removes shorter fibers, resulting in stronger, softer, and more durable fabric ideal for high-quality garments. Carded cotton, in contrast, is made by loosely untangling fibers, producing a coarser texture that is less smooth but more affordable. Choosing between combed and carded cotton depends on the desired fabric softness, strength, and budget.

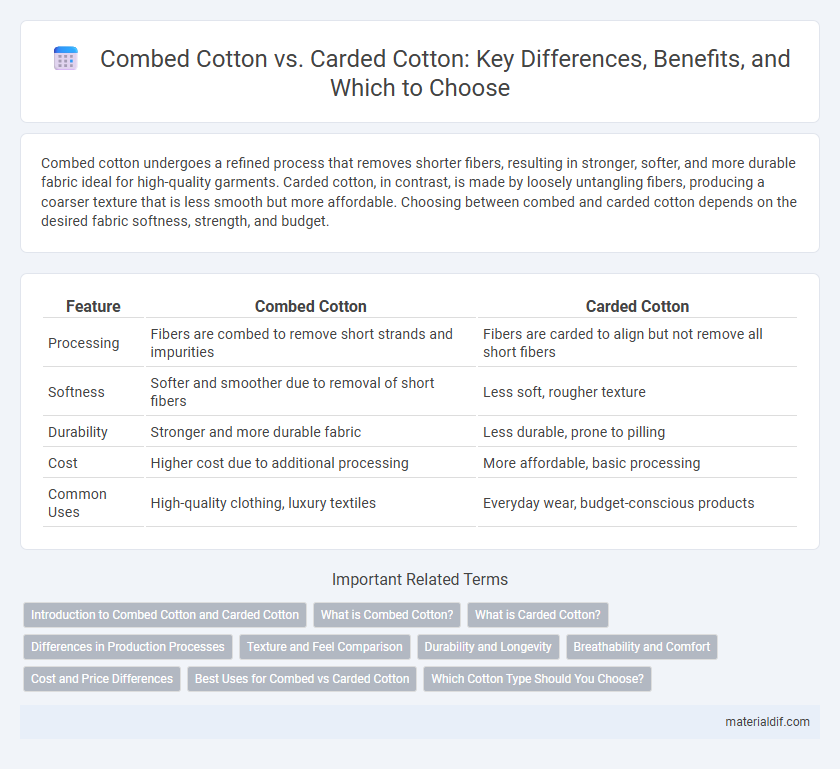

Table of Comparison

| Feature | Combed Cotton | Carded Cotton |

|---|---|---|

| Processing | Fibers are combed to remove short strands and impurities | Fibers are carded to align but not remove all short fibers |

| Softness | Softer and smoother due to removal of short fibers | Less soft, rougher texture |

| Durability | Stronger and more durable fabric | Less durable, prone to pilling |

| Cost | Higher cost due to additional processing | More affordable, basic processing |

| Common Uses | High-quality clothing, luxury textiles | Everyday wear, budget-conscious products |

Introduction to Combed Cotton and Carded Cotton

Combed cotton undergoes an extra step where fibers are carefully aligned and shorter strands are removed, resulting in a smoother, stronger, and finer fabric compared to carded cotton. Carded cotton is processed by disentangling and cleaning raw cotton fibers with a carding machine, producing a coarser, less refined textile that retains more impurities and can be less durable. The choice between combed and carded cotton directly affects fabric quality, softness, and longevity in textile products.

What is Combed Cotton?

Combed cotton is a premium type of cotton fabric made by carefully combing the cotton fibers to remove short strands and impurities, resulting in a smoother and stronger yarn. This process enhances the fabric's softness, durability, and overall quality compared to carded cotton, which retains more fiber irregularities. Combed cotton is commonly used in high-quality textiles such as luxury bedding, premium T-shirts, and fine apparel for its superior comfort and longevity.

What is Carded Cotton?

Carded cotton undergoes a mechanical process that disentangles, cleans, and intermixes cotton fibers to produce a continuous web suitable for spinning. This method removes impurities but leaves fibers less aligned and shorter compared to combed cotton, resulting in a coarser texture and slightly lower strength. Carded cotton is commonly used in affordable textiles where moderate softness and durability are acceptable.

Differences in Production Processes

Combed cotton undergoes an extra step where fibers are thoroughly cleaned and aligned using fine brushes, resulting in smoother and stronger yarn. Carded cotton fibers are simply disentangled and roughly aligned through a carding machine, producing a coarser texture. The combing process removes shorter fibers and impurities, enhancing fabric softness and durability compared to carded cotton.

Texture and Feel Comparison

Combed cotton undergoes an extra process where short fibers and impurities are removed, resulting in a smoother, finer texture and a softer, more luxurious feel compared to carded cotton. Carded cotton retains more of the rough fibers and natural debris, giving it a coarser texture and a slightly thicker, less refined surface. This difference in processing directly impacts the softness and durability of fabrics made from each type, with combed cotton offering superior comfort and a silkier touch.

Durability and Longevity

Combed cotton undergoes an extra process that removes short fibers and impurities, resulting in stronger, more durable yarn ideal for long-lasting fabrics. Carded cotton retains more short fibers, making it softer but less durable over time compared to combed cotton. Fabrics made from combed cotton exhibit greater resistance to wear and pilling, ensuring enhanced longevity in clothing and textiles.

Breathability and Comfort

Combed cotton undergoes an extra process that removes short fibers, resulting in a smoother, stronger fabric with superior breathability compared to carded cotton. The enhanced breathability of combed cotton allows better air circulation, reducing moisture buildup and increasing comfort, especially in warm climates. Carded cotton, while softer than regular cotton, tends to be less breathable and can feel heavier and less comfortable during extended wear.

Cost and Price Differences

Combed cotton undergoes an extra refining process to remove short fibers and impurities, resulting in a smoother, stronger fabric compared to carded cotton, which is more loosely processed. This additional step increases the production cost, making combed cotton significantly pricier than carded cotton in the textile market. Manufacturers and consumers pay a premium for combed cotton due to its superior quality, durability, and softer feel.

Best Uses for Combed vs Carded Cotton

Combed cotton features longer fibers removed from shorter strands, resulting in a smoother, stronger, and softer fabric ideal for premium clothing, baby garments, and luxury bedding. Carded cotton retains more fiber impurities and shorter strands, making it suitable for casual wear, towels, and basic home textiles where durability is prioritized over softness. Selecting combed cotton ensures enhanced comfort and durability for sensitive skin and high-end products, while carded cotton offers cost-effective options for everyday use.

Which Cotton Type Should You Choose?

Combed cotton offers superior softness and durability, making it ideal for high-quality garments requiring a smooth, luxurious feel. Carded cotton, processed with minimal fiber alignment, is more affordable and suitable for casual wear or products where comfort is prioritized over refinement. Choosing between combed and carded cotton depends on budget considerations and the desired texture and longevity of the final fabric.

Combed Cotton vs Carded Cotton Infographic

materialdif.com

materialdif.com