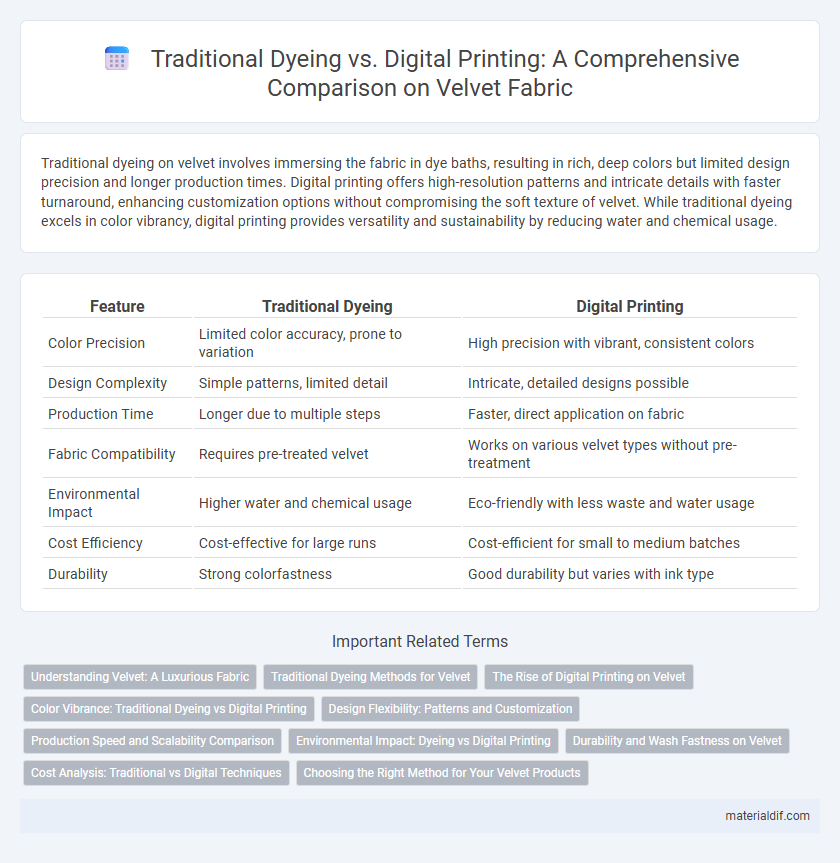

Traditional dyeing on velvet involves immersing the fabric in dye baths, resulting in rich, deep colors but limited design precision and longer production times. Digital printing offers high-resolution patterns and intricate details with faster turnaround, enhancing customization options without compromising the soft texture of velvet. While traditional dyeing excels in color vibrancy, digital printing provides versatility and sustainability by reducing water and chemical usage.

Table of Comparison

| Feature | Traditional Dyeing | Digital Printing |

|---|---|---|

| Color Precision | Limited color accuracy, prone to variation | High precision with vibrant, consistent colors |

| Design Complexity | Simple patterns, limited detail | Intricate, detailed designs possible |

| Production Time | Longer due to multiple steps | Faster, direct application on fabric |

| Fabric Compatibility | Requires pre-treated velvet | Works on various velvet types without pre-treatment |

| Environmental Impact | Higher water and chemical usage | Eco-friendly with less waste and water usage |

| Cost Efficiency | Cost-effective for large runs | Cost-efficient for small to medium batches |

| Durability | Strong colorfastness | Good durability but varies with ink type |

Understanding Velvet: A Luxurious Fabric

Velvet, a luxurious fabric known for its dense pile and soft texture, traditionally undergoes dyeing processes that enhance its rich colors through deep fabric penetration. Digital printing on velvet allows for intricate and precise patterns without compromising the fabric's plush feel, offering greater design versatility and color accuracy. Understanding the differences between traditional dyeing and digital printing on velvet helps optimize both aesthetic appeal and production efficiency in luxury textile applications.

Traditional Dyeing Methods for Velvet

Traditional dyeing methods for velvet involve immersing the fabric in natural or synthetic dyes, allowing deep color absorption that enhances the texture's luxurious appearance. Techniques such as vat dyeing and piece dyeing ensure vibrant, long-lasting hues that complement velvet's pile construction. These methods maintain the fabric's softness and richness, preserving the characteristic depth and sheen intrinsic to high-quality velvet.

The Rise of Digital Printing on Velvet

Digital printing on velvet has surged due to its ability to produce intricate, vibrant patterns with precise color accuracy, unmatched by traditional dyeing methods. This technology reduces production time and waste, offering designers greater flexibility and customization for luxury velvet textiles. As a result, digital printing is revolutionizing velvet manufacturing by enhancing efficiency and broadening creative possibilities.

Color Vibrance: Traditional Dyeing vs Digital Printing

Traditional dyeing on velvet offers rich, deep color vibrance due to the fabric's natural absorption of dyes, resulting in long-lasting, saturated hues. Digital printing enables precise color control and intricate designs with vibrant color output, but sometimes lacks the depth and intensity achieved through traditional methods. Both techniques impact velvet's color vibrance differently, with traditional dyeing excelling in depth and digital printing in detail and brightness.

Design Flexibility: Patterns and Customization

Traditional dyeing on velvet offers rich, deep colors but limits design flexibility due to fixed patterns and color constraints. Digital printing enables intricate, customizable patterns with vibrant hues, allowing precise replication of complex designs on velvet fabric. This technology supports rapid prototyping and personalized prints, making it ideal for diverse, unique velvet applications.

Production Speed and Scalability Comparison

Traditional dyeing on velvet involves labor-intensive processes that significantly slow production speed, making it less adaptable to large-scale orders. Digital printing accelerates production by enabling faster turnaround times and seamless scalability, meeting high-volume demands with consistent quality. This shift enhances efficiency in velvet textile manufacturing, reducing lead times and increasing output flexibility.

Environmental Impact: Dyeing vs Digital Printing

Traditional dyeing of velvet involves extensive water usage and chemical discharge, often leading to significant environmental pollution and resource depletion. Digital printing on velvet reduces water consumption by up to 90% and minimizes toxic effluents due to precise ink application and lower chemical use. This eco-friendly method also decreases energy consumption and waste, making digital printing a sustainable alternative to conventional dyeing processes.

Durability and Wash Fastness on Velvet

Traditional dyeing techniques on velvet offer excellent durability and wash fastness due to deep fiber penetration, resulting in colors that remain vibrant even after repeated laundering. Digital printing on velvet, while providing intricate and customizable designs, may have lower wash fastness as the pigment rests more on the surface and can fade faster over time. Selecting traditional dyeing ensures longer-lasting color retention on velvet, making it ideal for heavy-use applications where durability is critical.

Cost Analysis: Traditional vs Digital Techniques

Traditional dyeing of velvet involves labor-intensive processes and high consumption of water and dyes, leading to increased production costs and environmental impact. Digital printing on velvet significantly reduces material waste and energy usage by applying precise amounts of ink directly to the fabric, resulting in lower operational expenses and faster turnaround times. While initial investment for digital printers is higher, long-term cost savings in labor, materials, and time make digital printing a more economical choice for customized velvet designs.

Choosing the Right Method for Your Velvet Products

Traditional dyeing on velvet offers rich, deep color saturation and a tactile texture that enhances the fabric's luxurious feel, ideal for classic and ornate designs. Digital printing provides unparalleled precision and customization with vibrant patterns and faster turnaround times, perfect for contemporary and intricate motifs. Selecting the right method depends on factors like design complexity, production volume, color vibrancy, and budget constraints to achieve the desired aesthetic and functional outcomes for velvet products.

Traditional Dyeing vs Digital Printing (on Velvet) Infographic

materialdif.com

materialdif.com