Hand-dyed velvet offers unique color variations and a rich depth that machine-dyed velvet cannot replicate, providing a luxurious and artisanal finish. Each piece of hand-dyed velvet is one-of-a-kind, with subtle nuances and a softer texture that enhances its tactile appeal. Machine-dyed velvet delivers consistent, uniform colors ideal for large-scale production but lacks the individuality and handcrafted charm found in hand-dyed fabrics.

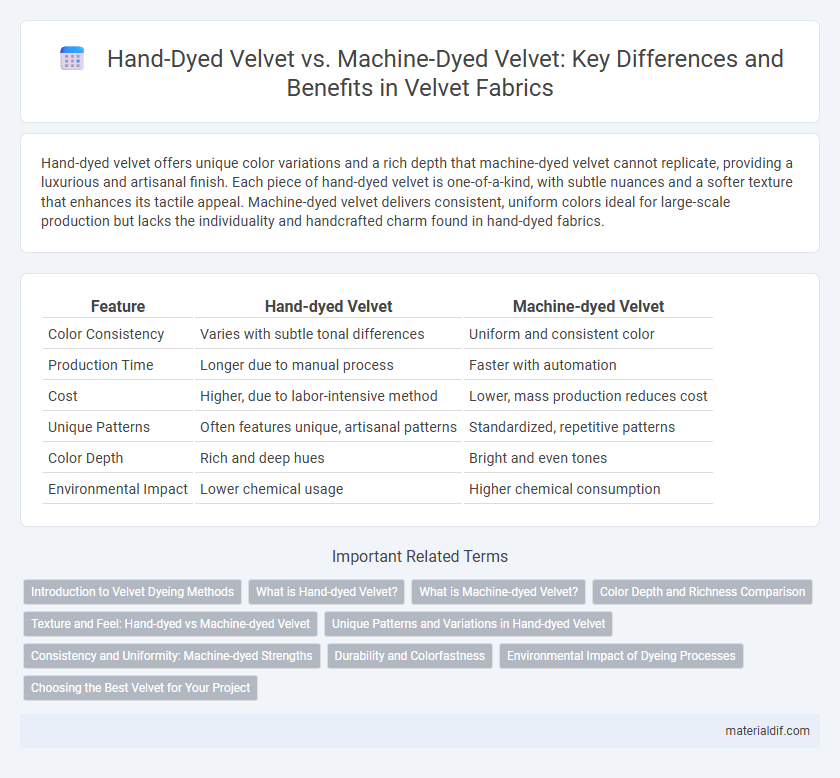

Table of Comparison

| Feature | Hand-dyed Velvet | Machine-dyed Velvet |

|---|---|---|

| Color Consistency | Varies with subtle tonal differences | Uniform and consistent color |

| Production Time | Longer due to manual process | Faster with automation |

| Cost | Higher, due to labor-intensive method | Lower, mass production reduces cost |

| Unique Patterns | Often features unique, artisanal patterns | Standardized, repetitive patterns |

| Color Depth | Rich and deep hues | Bright and even tones |

| Environmental Impact | Lower chemical usage | Higher chemical consumption |

Introduction to Velvet Dyeing Methods

Hand-dyed velvet showcases unique color variations and depth due to the artisan application process, enhancing its luxurious texture and visual appeal. Machine-dyed velvet ensures consistent color saturation and uniformity across large fabric batches, optimizing efficiency for mass production. Both dyeing methods influence the final velvet quality, with hand-dyeing emphasizing individuality and machine-dyeing prioritizing scalability.

What is Hand-dyed Velvet?

Hand-dyed velvet is a luxurious fabric crafted through an artisanal process where dyes are manually applied, resulting in unique variations in color and texture. This meticulous technique enhances the richness and depth of the velvet, creating one-of-a-kind patterns that machine-dyed velvet cannot replicate. Hand-dyed velvet is prized for its artisanal quality, vibrant hues, and the subtle irregularities that add character and exclusivity to high-end fashion and interior designs.

What is Machine-dyed Velvet?

Machine-dyed velvet is a type of fabric colored using automated dyeing equipment that ensures uniform color application and consistency across large batches. This process uses precise temperature and pressure control to penetrate fibers evenly, resulting in vibrant and durable hues. Machine-dyed velvet is ideal for mass production, offering efficiency and repeatability compared to traditional hand-dyeing methods.

Color Depth and Richness Comparison

Hand-dyed velvet exhibits superior color depth and richness due to the artisanal application of dyes, allowing for subtle variations and intense pigmentation that create a more vibrant and textured appearance. Machine-dyed velvet often results in uniform coloration but lacks the complex tonality and dimensionality found in hand-dyed fabrics. The uneven absorption of dyes in hand-dyeing processes enhances the plush fabric's tactile and visual qualities, making it highly prized for luxury textiles and designer upholstery.

Texture and Feel: Hand-dyed vs Machine-dyed Velvet

Hand-dyed velvet typically offers a richer, more varied texture with subtle color gradients that highlight the fabric's natural depth and softness. Machine-dyed velvet tends to have a more uniform color, resulting in a smoother but less nuanced feel across the surface. The artisanal process of hand-dyeing enhances the tactile experience, making each piece of velvet uniquely plush and visually dynamic compared to the consistent finish of machine-dyed fabric.

Unique Patterns and Variations in Hand-dyed Velvet

Hand-dyed velvet showcases unique patterns and subtle variations in color intensity that machine-dyed velvet cannot replicate, resulting in one-of-a-kind fabric pieces. Each hand-dyed velvet is crafted individually, allowing for rich textures and depth within the pile, enhancing its luxurious appeal. The artisanal process introduces organic imperfections that add character and exclusivity to garments and upholstery.

Consistency and Uniformity: Machine-dyed Strengths

Machine-dyed velvet offers superior consistency and uniformity in color application compared to hand-dyed velvet, ensuring every yard matches perfectly within large production runs. The precision of industrial dyeing machines allows for controlled temperature, timing, and dye concentration, resulting in even saturation and repeatable shades. This reliable uniformity makes machine-dyed velvet the preferred choice for mass manufacturing and commercial textile applications where color accuracy is critical.

Durability and Colorfastness

Hand-dyed velvet exhibits unique color variations but typically has lower colorfastness and durability compared to machine-dyed velvet, which undergoes uniform dyeing processes ensuring consistent, long-lasting color and enhanced fiber strength. Machine-dyed velvet maintains better resistance to fading and wear from washing and sunlight exposure, making it more suitable for high-use applications. The precision of industrial dyeing methods in machine-dyed velvet results in superior performance characteristics critical for upholstery and fashion products demanding longevity.

Environmental Impact of Dyeing Processes

Hand-dyed velvet utilizes natural dyes and small-batch techniques, resulting in lower water consumption and minimal chemical waste compared to machine-dyed velvet, which often relies on synthetic dyes and large-scale industrial processes. Machine-dyed velvet tends to generate significant effluent contamination and higher energy usage due to continuous dyeing cycles and extensive water treatment requirements. Choosing hand-dyed velvet supports sustainable textile production by reducing pollution and conserving resources throughout the dyeing process.

Choosing the Best Velvet for Your Project

Hand-dyed velvet offers unique color variations and a rich, artisanal texture, making it ideal for bespoke or high-end design projects where character and individuality are prioritized. Machine-dyed velvet provides consistent color uniformity and scalability, suited for large-scale production and commercial applications requiring reliability. Selecting the best velvet depends on project needs: hand-dyed velvet enhances exclusivity and craftsmanship, while machine-dyed velvet ensures precision and efficiency.

Hand-dyed Velvet vs Machine-dyed Velvet Infographic

materialdif.com

materialdif.com