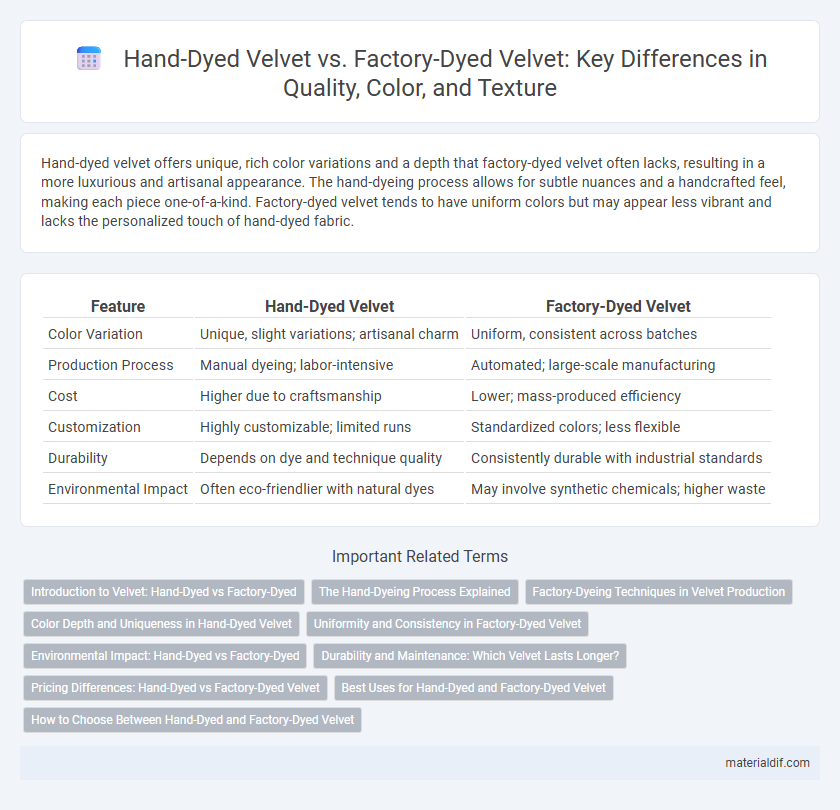

Hand-dyed velvet offers unique, rich color variations and a depth that factory-dyed velvet often lacks, resulting in a more luxurious and artisanal appearance. The hand-dyeing process allows for subtle nuances and a handcrafted feel, making each piece one-of-a-kind. Factory-dyed velvet tends to have uniform colors but may appear less vibrant and lacks the personalized touch of hand-dyed fabric.

Table of Comparison

| Feature | Hand-Dyed Velvet | Factory-Dyed Velvet |

|---|---|---|

| Color Variation | Unique, slight variations; artisanal charm | Uniform, consistent across batches |

| Production Process | Manual dyeing; labor-intensive | Automated; large-scale manufacturing |

| Cost | Higher due to craftsmanship | Lower; mass-produced efficiency |

| Customization | Highly customizable; limited runs | Standardized colors; less flexible |

| Durability | Depends on dye and technique quality | Consistently durable with industrial standards |

| Environmental Impact | Often eco-friendlier with natural dyes | May involve synthetic chemicals; higher waste |

Introduction to Velvet: Hand-Dyed vs Factory-Dyed

Hand-dyed velvet showcases unique color variations and subtle irregularities that highlight artisanal craftsmanship, making each piece distinct. Factory-dyed velvet offers consistent, uniform coloration achieved through automated processes ideal for large-scale production and standardization. Understanding the differences in dyeing techniques helps in selecting velvet that matches desired aesthetics and quality standards.

The Hand-Dyeing Process Explained

Hand-dyed velvet undergoes a meticulous process where artisans immerse fabric sections into dye baths, allowing for variations in color intensity and unique texture patterns. This slow, manual technique enhances the fabric's depth and richness, producing one-of-a-kind hues that factory-dyed velvet lacks. Factory-dyed velvet, in contrast, uses automated machinery ensuring uniformity but sacrificing the intricate, organic nuances achieved through hand-dyeing.

Factory-Dyeing Techniques in Velvet Production

Factory-dyeing techniques in velvet production utilize advanced machinery and controlled environments to ensure color consistency and fast processing, resulting in uniform hues across large fabric batches. These methods often involve continuous dyeing or piece-dyeing processes that tightly regulate temperature and dye concentration to enhance colorfastness and reduce production time. Factory-dyed velvet is favored for commercial applications due to its scalability, cost-efficiency, and reliable quality compared to hand-dyed alternatives.

Color Depth and Uniqueness in Hand-Dyed Velvet

Hand-dyed velvet boasts unparalleled color depth due to the artisanal dyeing process, which allows individual fibers to absorb rich pigments unevenly, creating a vibrant, multi-dimensional effect. This method ensures each velvet piece is unique, showcasing subtle variations in shade and intensity that factory-dyed velvet cannot replicate. Factory-dyed velvet, by comparison, often has a uniform color finish lacking the distinctive character and organic richness found in hand-dyed alternatives.

Uniformity and Consistency in Factory-Dyed Velvet

Factory-dyed velvet ensures uniform color distribution throughout each yard of fabric, providing consistent hues ideal for large-scale production and precise color matching. The controlled dyeing process minimizes variation between batches, delivering reliable consistency that hand-dyed velvet often lacks due to its artisanal nature. This consistency makes factory-dyed velvet preferable for designers and manufacturers requiring exact color replication and standardization across products.

Environmental Impact: Hand-Dyed vs Factory-Dyed

Hand-dyed velvet significantly reduces environmental impact by using natural dyes and minimizing water waste compared to factory-dyed velvet, which often relies on synthetic dyes and large-scale chemical processing. Factory-dyeing processes contribute to higher carbon emissions and water pollution due to intensive energy consumption and runoff from toxic substances. Choosing hand-dyed velvet supports sustainable textile production by promoting eco-friendly methods and reducing harmful environmental footprints.

Durability and Maintenance: Which Velvet Lasts Longer?

Hand-dyed velvet offers unique color variations but often requires more delicate care to maintain its vibrancy, as the dyes can be less stable compared to factory-dyed velvet. Factory-dyed velvet undergoes controlled processes ensuring better colorfastness and durability, making it more resistant to fading and wear over time. Proper maintenance for both involves gentle cleaning methods, but factory-dyed velvet generally lasts longer due to its consistent dye application and enhanced fiber treatment.

Pricing Differences: Hand-Dyed vs Factory-Dyed Velvet

Hand-dyed velvet typically commands higher prices due to the labor-intensive process and the uniqueness of each piece, with costs often ranging from $50 to $150 per yard. Factory-dyed velvet benefits from mass production techniques, resulting in lower prices generally between $20 and $60 per yard. The pricing difference also reflects the artisanal value of hand-dyeing compared to the uniformity and consistency of factory-dyed velvet.

Best Uses for Hand-Dyed and Factory-Dyed Velvet

Hand-dyed velvet offers unique variations in color and texture, making it ideal for artisanal fashion, bespoke upholstery, and luxury home decor where distinctiveness is valued. Factory-dyed velvet provides consistent, uniform coloration, perfect for large-scale production in apparel, drapery, and commercial furnishings requiring color precision and durability. Choosing between hand-dyed and factory-dyed velvet depends on the desired aesthetic, production scale, and application environment.

How to Choose Between Hand-Dyed and Factory-Dyed Velvet

Hand-dyed velvet offers unique color variations and artisanal quality, making it ideal for custom, high-end projects requiring distinct textures and depth. Factory-dyed velvet ensures color consistency, durability, and cost-effectiveness, suitable for large-scale productions and uniform applications. Selecting between hand-dyed and factory-dyed velvet depends on the desired level of uniqueness, budget constraints, and specific project requirements for texture and color precision.

Hand-Dyed Velvet vs Factory-Dyed Velvet Infographic

materialdif.com

materialdif.com