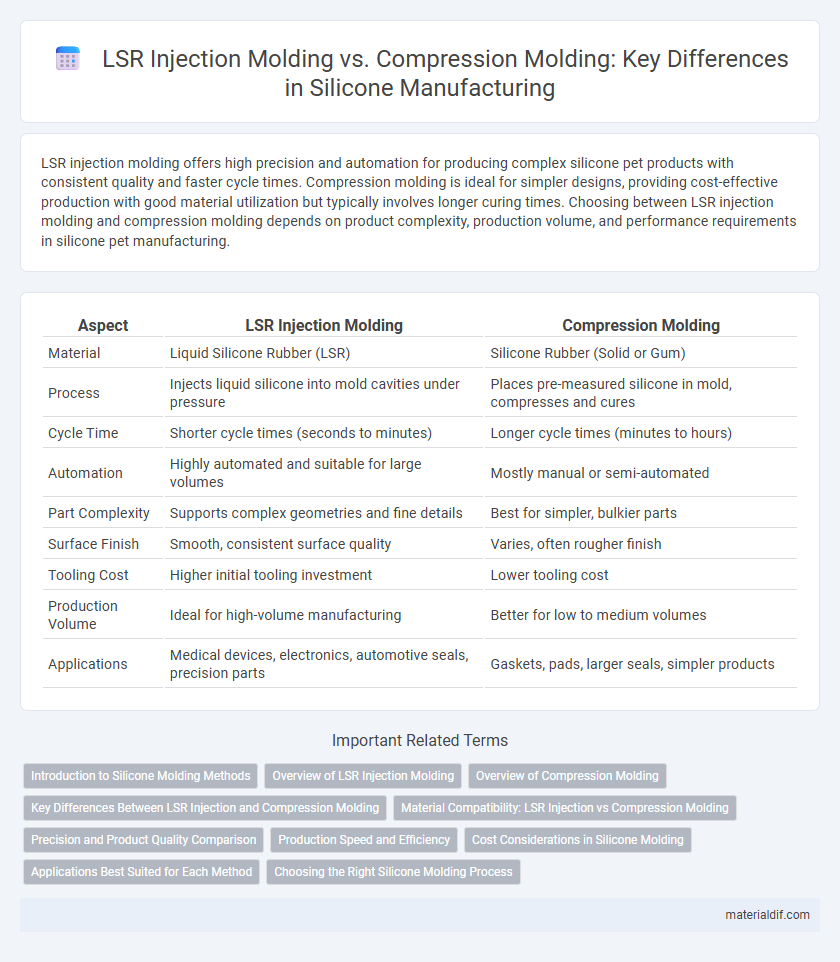

LSR injection molding offers high precision and automation for producing complex silicone pet products with consistent quality and faster cycle times. Compression molding is ideal for simpler designs, providing cost-effective production with good material utilization but typically involves longer curing times. Choosing between LSR injection molding and compression molding depends on product complexity, production volume, and performance requirements in silicone pet manufacturing.

Table of Comparison

| Aspect | LSR Injection Molding | Compression Molding |

|---|---|---|

| Material | Liquid Silicone Rubber (LSR) | Silicone Rubber (Solid or Gum) |

| Process | Injects liquid silicone into mold cavities under pressure | Places pre-measured silicone in mold, compresses and cures |

| Cycle Time | Shorter cycle times (seconds to minutes) | Longer cycle times (minutes to hours) |

| Automation | Highly automated and suitable for large volumes | Mostly manual or semi-automated |

| Part Complexity | Supports complex geometries and fine details | Best for simpler, bulkier parts |

| Surface Finish | Smooth, consistent surface quality | Varies, often rougher finish |

| Tooling Cost | Higher initial tooling investment | Lower tooling cost |

| Production Volume | Ideal for high-volume manufacturing | Better for low to medium volumes |

| Applications | Medical devices, electronics, automotive seals, precision parts | Gaskets, pads, larger seals, simpler products |

Introduction to Silicone Molding Methods

Liquid Silicone Rubber (LSR) injection molding and compression molding are two primary methods used in silicone manufacturing, each offering distinct advantages for producing high-precision silicone parts. LSR injection molding utilizes automated machinery to inject heated silicone into molds, ensuring fast cycle times and consistent product quality, especially suitable for complex geometries. Compression molding involves placing pre-measured silicone material into a heated mold, then applying pressure to shape the part, providing cost-effective tooling options for larger, simpler designs.

Overview of LSR Injection Molding

LSR injection molding offers precise control over silicone liquid rubber, enabling complex geometries with high repeatability and minimal waste. This process involves injecting liquid silicone rubber into a heated mold cavity, where it cures quickly, resulting in faster cycle times compared to compression molding. Its automation capabilities and ability to produce consistent, high-quality parts make LSR injection molding ideal for medical, automotive, and electronics applications.

Overview of Compression Molding

Compression molding is a manufacturing process where liquid silicone rubber (LSR) or solid silicone is placed into a heated mold cavity, then compressed under high pressure to conform to the mold shape. This method allows for precise control over curing time and temperature, making it ideal for producing large, complex silicone parts with consistent quality. Compression molding offers advantages such as lower tooling costs and reduced waste, particularly beneficial for small to medium production runs of durable silicone components.

Key Differences Between LSR Injection and Compression Molding

LSR injection molding uses liquid silicone rubber injected into a mold cavity under high pressure, allowing for complex shapes and fast cycle times, whereas compression molding involves placing a pre-measured amount of silicone into the mold and applying heat and pressure to shape it. Injection molding offers superior precision, consistent part quality, and is suitable for high-volume production, while compression molding is better for larger, simpler parts and lower production volumes. The choice between LSR injection and compression molding depends on factors such as part complexity, production speed, and cost-efficiency.

Material Compatibility: LSR Injection vs Compression Molding

Liquid Silicone Rubber (LSR) injection molding offers superior material compatibility compared to compression molding due to its ability to process high-purity, low-viscosity silicones with consistent curing and minimal waste. Compression molding is more suitable for solid or higher viscosity silicone compounds but often results in variable material flow and less uniform cross-linking. LSR injection molding enhances precision in mixing and dispersion, ensuring excellent physical properties and biocompatibility essential for medical-grade silicone components.

Precision and Product Quality Comparison

LSR injection molding offers superior precision through automated, controlled material injection, producing complex shapes with tight tolerances and consistent part dimensions. Compression molding provides good quality for simpler designs but often lacks the fine detail accuracy and uniformity achievable with LSR injection molding. Product quality in LSR injection molding is enhanced by reduced material waste, minimal flash, and enhanced repeatability, making it ideal for high-volume, precision silicone components.

Production Speed and Efficiency

LSR injection molding offers significantly higher production speed compared to compression molding, enabling rapid cycle times of 20 to 60 seconds per part. This method ensures consistent part quality with automated processes, boosting overall efficiency in high-volume manufacturing. Compression molding, while cost-effective for small runs, involves longer cure times and manual labor that reduce throughput and scalability.

Cost Considerations in Silicone Molding

LSR injection molding typically incurs higher upfront costs due to expensive molds and specialized machinery but offers lower per-unit expenses in large production runs. In contrast, compression molding requires less initial investment, making it ideal for small batches or prototyping with faster mold fabrication. Evaluating production volume and complexity is crucial for optimizing cost efficiency in silicone molding processes.

Applications Best Suited for Each Method

LSR injection molding excels in producing complex, high-precision silicone parts such as medical devices, automotive components, and consumer electronics due to its automation and fast cycle times. Compression molding is ideal for simpler, larger silicone products like gaskets, seals, and kitchenware where low tooling costs and flexibility in material thickness are essential. Each method caters to different production volumes and product intricacies, with injection molding suited for mass production and compression molding for smaller runs or bulky parts.

Choosing the Right Silicone Molding Process

Choosing the right silicone molding process depends on production volume, complexity, and material properties. LSR injection molding offers high precision and is ideal for complex parts with tight tolerances in large-scale production, while compression molding suits lower volume runs and simpler geometries. Evaluating factors such as cycle time, cost-effectiveness, and mechanical performance guides the selection between Liquid Silicone Rubber (LSR) injection and compression molding techniques.

LSR Injection Molding vs Compression Molding Infographic

materialdif.com

materialdif.com