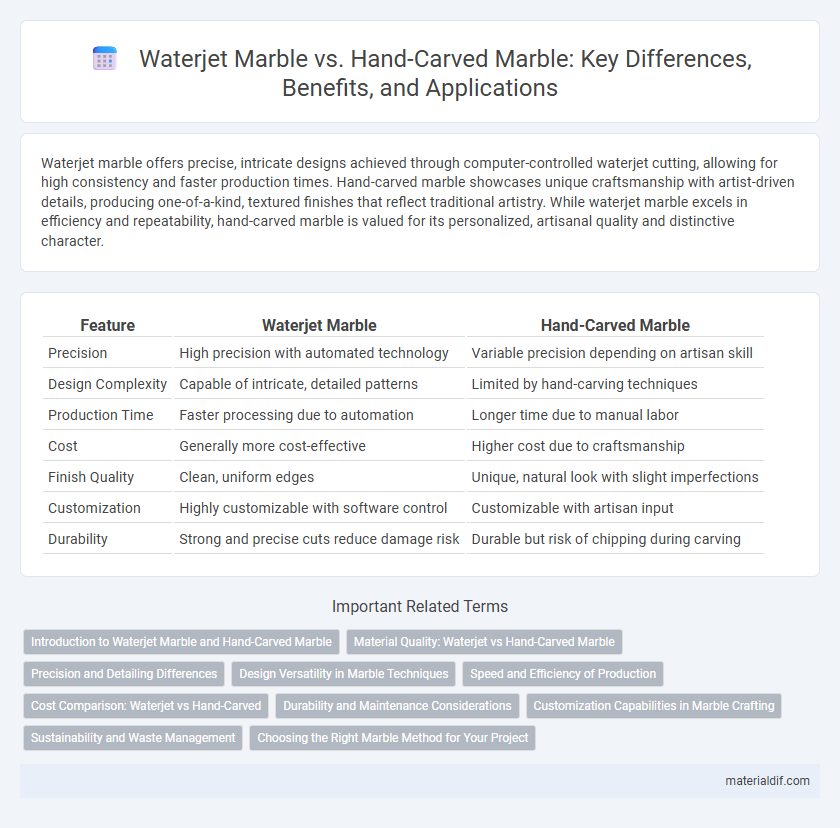

Waterjet marble offers precise, intricate designs achieved through computer-controlled waterjet cutting, allowing for high consistency and faster production times. Hand-carved marble showcases unique craftsmanship with artist-driven details, producing one-of-a-kind, textured finishes that reflect traditional artistry. While waterjet marble excels in efficiency and repeatability, hand-carved marble is valued for its personalized, artisanal quality and distinctive character.

Table of Comparison

| Feature | Waterjet Marble | Hand-Carved Marble |

|---|---|---|

| Precision | High precision with automated technology | Variable precision depending on artisan skill |

| Design Complexity | Capable of intricate, detailed patterns | Limited by hand-carving techniques |

| Production Time | Faster processing due to automation | Longer time due to manual labor |

| Cost | Generally more cost-effective | Higher cost due to craftsmanship |

| Finish Quality | Clean, uniform edges | Unique, natural look with slight imperfections |

| Customization | Highly customizable with software control | Customizable with artisan input |

| Durability | Strong and precise cuts reduce damage risk | Durable but risk of chipping during carving |

Introduction to Waterjet Marble and Hand-Carved Marble

Waterjet marble utilizes advanced high-pressure waterjet technology combined with abrasive materials to precisely cut intricate designs, enabling rapid production and consistent accuracy. Hand-carved marble relies on skilled artisans manually sculpting stone, resulting in unique, detailed patterns that reflect traditional craftsmanship but require significantly more time. The choice between waterjet and hand-carved marble impacts project timelines, customization level, and overall cost efficiency.

Material Quality: Waterjet vs Hand-Carved Marble

Waterjet marble maintains consistent material quality by precisely cutting stone slabs with high-pressure water, minimizing cracks and preserving the marble's natural integrity. Hand-carved marble, while offering unique artisanal details, may introduce slight imperfections due to manual chiseling, which can affect structural uniformity. Both techniques use high-grade marble, but waterjet cutting ensures sharper edges and uniform thickness, enhancing durability and finish quality.

Precision and Detailing Differences

Waterjet marble cutting employs high-pressure water mixed with abrasive materials to achieve precise and intricate designs, producing consistent and clean edges ideal for complex patterns. Hand-carved marble showcases artisanal craftsmanship characterized by slight variations and unique textures, reflecting skillful, detailed workmanship that machines may not replicate. Precision in waterjet carving surpasses manual methods by delivering uniformity, while hand-carving emphasizes artistic expression and subtle detailing.

Design Versatility in Marble Techniques

Waterjet marble offers exceptional design versatility by enabling precise and intricate patterns that are difficult to achieve with traditional hand-carving methods. This technique allows for complex geometric shapes and detailed inlays with consistent accuracy, expanding creative possibilities in marble applications. Hand-carved marble, while rich in artisanal value, is limited by the skill and time required, making it less adaptable for highly detailed or repetitive designs.

Speed and Efficiency of Production

Waterjet marble cutting offers significantly faster production speeds compared to traditional hand-carved methods, utilizing high-pressure water jets to precisely shape intricate designs in a fraction of the time. This technology enhances efficiency by reducing labor-intensive processes and minimizing material waste, allowing for consistent replication of complex patterns. In contrast, hand-carved marble requires skilled artisans and extended hours, leading to slower output and higher costs per piece.

Cost Comparison: Waterjet vs Hand-Carved

Waterjet marble cutting typically offers lower overall costs compared to hand-carved marble due to its precision and automation, reducing labor expenses. Hand-carved marble involves skilled artisans whose time-intensive work increases the price, especially for intricate designs. Budget-conscious projects often favor waterjet technology for its efficiency and consistent quality without sacrificing aesthetic appeal.

Durability and Maintenance Considerations

Waterjet marble offers precise, uniform cuts that reduce the risk of fractures, resulting in enhanced durability compared to hand-carved marble, which may have natural inconsistencies due to manual techniques. Maintenance for waterjet marble is generally lower since its smooth, even surface resists dirt accumulation and chipping, while hand-carved marble requires regular sealing and careful cleaning to preserve intricate details. Both types benefit from sealing, but waterjet marble's uniformity often extends the intervals between maintenance treatments.

Customization Capabilities in Marble Crafting

Waterjet marble offers unparalleled customization capabilities with precision cutting powered by advanced CAD technology, enabling intricate designs and complex patterns unattainable by hand. Hand-carved marble provides a unique artisanal touch and organic detail, but limited flexibility in replication and fine detail compared to waterjet methods. The waterjet technique excels in delivering consistent, scalable custom marble pieces ideal for modern architectural and artistic projects.

Sustainability and Waste Management

Waterjet marble processing reduces material waste by using precise, computer-controlled cutting techniques, minimizing offcuts compared to hand-carved marble, which often generates more scrap due to manual shaping. The waterjet method also supports sustainable practices by recycling water and avoiding heat or chemical use, whereas hand-carving typically involves higher energy consumption and dust production. Overall, waterjet marble offers a cleaner, more eco-friendly approach to sustainability and waste management in stone fabrication.

Choosing the Right Marble Method for Your Project

Waterjet marble offers unparalleled precision and intricate designs by using high-pressure water mixed with abrasives to cut through stone, making it ideal for complex patterns and repeatability in large projects. Hand-carved marble showcases artisanal craftsmanship, delivering unique, detailed, and textured finishes that highlight traditional skills and craftsmanship for bespoke or artistic applications. Selecting the right marble method depends on the project's scale, design complexity, budget, and desired aesthetic, with waterjet excelling in accuracy and efficiency, while hand-carving emphasizes individuality and texture.

Waterjet Marble vs Hand-Carved Marble Infographic

materialdif.com

materialdif.com