Linen processing involves extracting fibers from flax plants through retting, scutching, and hackling, resulting in stronger and more durable fabric compared to cotton. Cotton processing centers on harvesting, ginning, and carding fibers from cotton bolls, producing softer and more breathable textiles. Linen's natural texture and breathability suit warmer climates, while cotton's versatility and ease of dyeing make it ideal for varied applications.

Table of Comparison

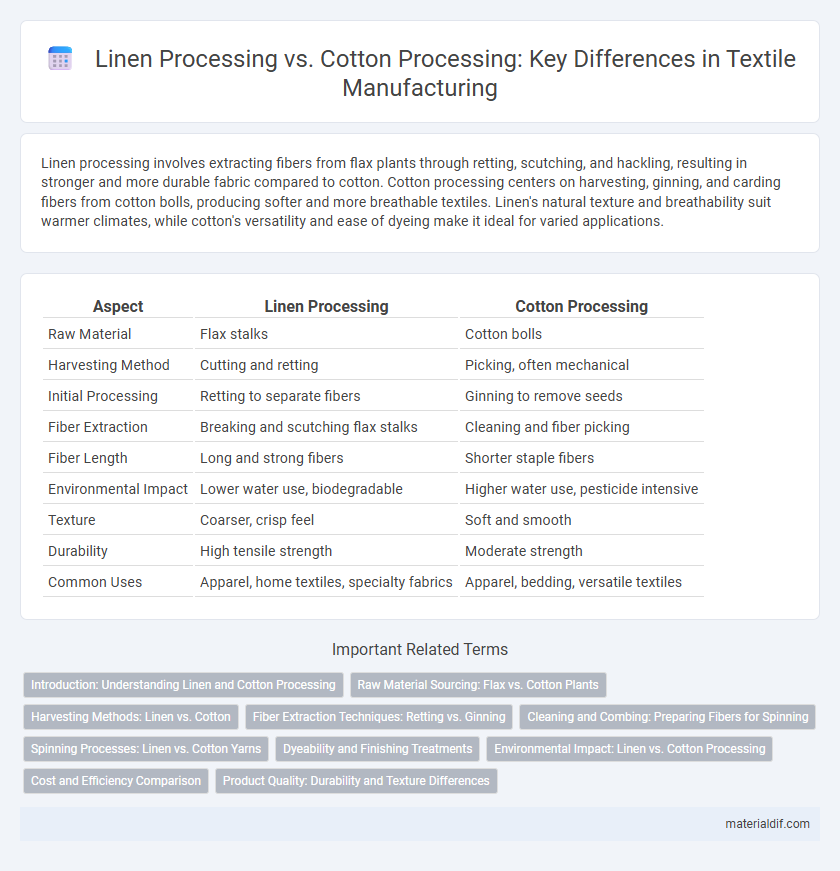

| Aspect | Linen Processing | Cotton Processing |

|---|---|---|

| Raw Material | Flax stalks | Cotton bolls |

| Harvesting Method | Cutting and retting | Picking, often mechanical |

| Initial Processing | Retting to separate fibers | Ginning to remove seeds |

| Fiber Extraction | Breaking and scutching flax stalks | Cleaning and fiber picking |

| Fiber Length | Long and strong fibers | Shorter staple fibers |

| Environmental Impact | Lower water use, biodegradable | Higher water use, pesticide intensive |

| Texture | Coarser, crisp feel | Soft and smooth |

| Durability | High tensile strength | Moderate strength |

| Common Uses | Apparel, home textiles, specialty fabrics | Apparel, bedding, versatile textiles |

Introduction: Understanding Linen and Cotton Processing

Linen processing involves harvesting flax plants, retting to separate fibers, and scutching to remove woody parts, resulting in long, strong fibers ideal for durable textiles. Cotton processing starts with picking cotton bolls, ginning to separate fibers from seeds, and carding to align fibers for spinning, producing soft, breathable fabric. These distinct techniques influence the texture, strength, and environmental impact of linen and cotton products in textile manufacturing.

Raw Material Sourcing: Flax vs. Cotton Plants

Linen processing begins with sourcing flax, a bast fiber derived from the stems of the flax plant, which requires cooler climates and well-drained soils for optimal growth. Cotton processing utilizes cotton fibers harvested from seed hairs of the cotton plant, thriving in warmer, more humid environments. The sustainable cultivation of flax often results in a more environmentally friendly raw material compared to cotton, which demands higher water and pesticide inputs.

Harvesting Methods: Linen vs. Cotton

Linen processing begins with harvesting flax plants by pulling or cutting to preserve the fibers' strength, while cotton harvesting involves carefully picking cotton bolls either by hand or machine to protect the delicate fibers. Flax requires a dew-retting process to separate fibers from the stalks, whereas cotton fibers are extracted directly from the bolls after harvesting. These distinct harvesting methods impact the overall fiber quality and environmental footprint of linen and cotton textiles.

Fiber Extraction Techniques: Retting vs. Ginning

Linen processing relies on retting, a biological method that uses moisture and microbes to break down the pectin binding flax fibers, allowing for gentle extraction of long, strong fibers ideal for high-quality textile production. In contrast, cotton processing employs ginning, a mechanical technique that separates cotton fibers from seeds quickly but results in shorter fibers suitable for mass-produced textiles. The retting process in linen preserves fiber length and strength, enhancing fabric durability, whereas ginning prioritizes speed and efficiency, often at the expense of fiber integrity.

Cleaning and Combing: Preparing Fibers for Spinning

Linen processing involves retting and scutching to separate and clean flax fibers, followed by hackling to align and comb the fibers for spinning, resulting in long, smooth strands ideal for fine textiles. Cotton processing relies on ginning to remove seeds and impurities, then carding to detangle and align shorter fibers, creating a soft, fluffy fiber mass suitable for spinning. The cleaning and combing stages in linen demand more mechanical and chemical treatments compared to cotton, reflecting the inherent differences in fiber structure and preparation methods.

Spinning Processes: Linen vs. Cotton Yarns

Linen spinning involves a wet spinning process that strengthens the flax fibers, enhancing yarn durability and smoothness, while cotton spinning primarily uses dry spinning techniques suited for its shorter fibers, resulting in softer, more elastic yarns. The longer flax fibers in linen produce yarns that are stronger and more lustrous compared to the staple fibers of cotton, which yield fluffier and less rigid yarns. Linen yarns require less twisting due to their natural fiber strength, whereas cotton yarns demand higher twist levels to increase coherence and reduce breakage during weaving.

Dyeability and Finishing Treatments

Linen processing involves retting and scutching to extract fibers, resulting in a fabric with high absorbency and excellent dye retention, producing vibrant and long-lasting colors. Cotton processing includes ginning and carding, which create a softer fiber but with moderate dye affinity, often requiring additional mordants or synthetic dyes for uniform coloration. Finishing treatments for linen enhance its natural luster and strength, while cotton finishes focus on softness and wrinkle resistance, influencing the final texture and appearance of each textile.

Environmental Impact: Linen vs. Cotton Processing

Linen processing requires significantly less water than cotton cultivation, reducing strain on freshwater resources and lowering environmental impact. The flax plant used for linen grows with fewer pesticides and herbicides, promoting biodiversity and soil health compared to chemically intensive cotton farming. Linen fibers also biodegrade faster, contributing to a smaller ecological footprint throughout the product lifecycle.

Cost and Efficiency Comparison

Linen processing, derived from flax fibers, typically incurs higher initial costs due to labor-intensive retting and scutching methods, whereas cotton processing benefits from mechanized ginning, reducing overall expenses. Linen's production is more time-consuming but yields a stronger, more durable fabric, offering long-term value despite higher upfront costs. Cotton processing is generally more efficient and scalable, supporting mass production with lower energy consumption and faster cycle times.

Product Quality: Durability and Texture Differences

Linen processing, derived from flax fibers, results in fabric known for superior durability and a distinct, textured feel compared to cotton, which is softer but less resilient. The retting and scutching processes in linen production strengthen the fibers, enhancing fabric longevity and breathability. Cotton processing involves ginning and carding that produce a smoother texture but yield fabric prone to wear over time and less moisture-wicking ability.

Linen Processing vs Cotton Processing Infographic

materialdif.com

materialdif.com