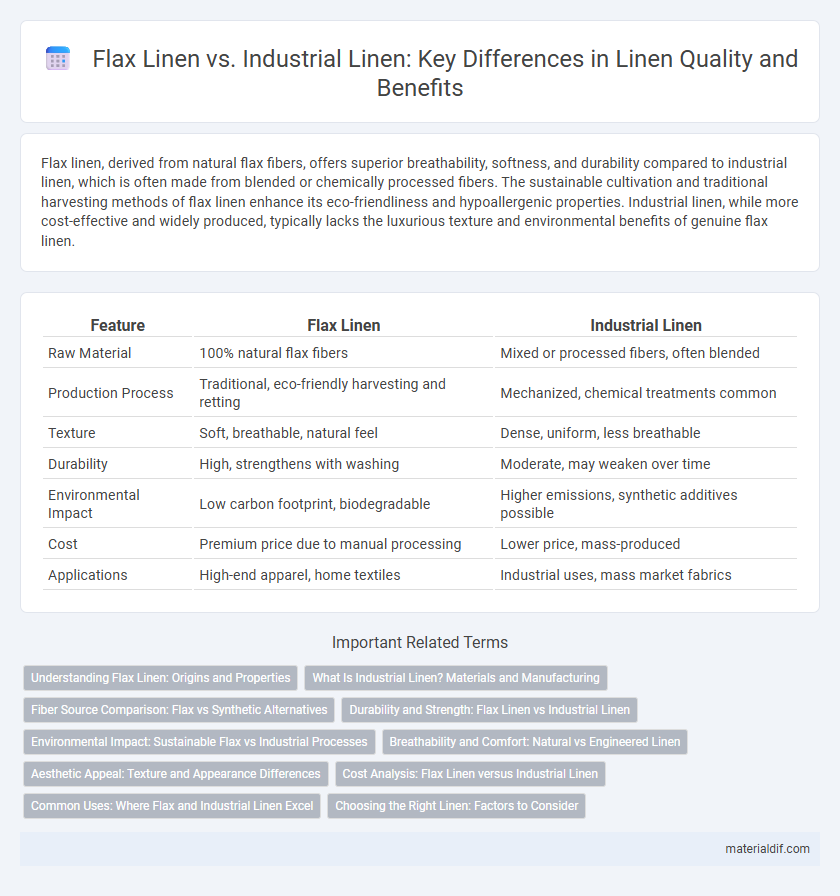

Flax linen, derived from natural flax fibers, offers superior breathability, softness, and durability compared to industrial linen, which is often made from blended or chemically processed fibers. The sustainable cultivation and traditional harvesting methods of flax linen enhance its eco-friendliness and hypoallergenic properties. Industrial linen, while more cost-effective and widely produced, typically lacks the luxurious texture and environmental benefits of genuine flax linen.

Table of Comparison

| Feature | Flax Linen | Industrial Linen |

|---|---|---|

| Raw Material | 100% natural flax fibers | Mixed or processed fibers, often blended |

| Production Process | Traditional, eco-friendly harvesting and retting | Mechanized, chemical treatments common |

| Texture | Soft, breathable, natural feel | Dense, uniform, less breathable |

| Durability | High, strengthens with washing | Moderate, may weaken over time |

| Environmental Impact | Low carbon footprint, biodegradable | Higher emissions, synthetic additives possible |

| Cost | Premium price due to manual processing | Lower price, mass-produced |

| Applications | High-end apparel, home textiles | Industrial uses, mass market fabrics |

Understanding Flax Linen: Origins and Properties

Flax linen is derived from the fibers of the flax plant, known for its natural strength, breathability, and eco-friendly qualities, distinguishing it from industrial linen produced through synthetic processes. The origins of flax linen date back thousands of years, prized for its durability, moisture-wicking ability, and temperature regulation, making it ideal for clothing and home textiles. Its properties include a smooth texture, hypoallergenic nature, and biodegradability, emphasizing sustainability compared to conventional industrial linen alternatives.

What Is Industrial Linen? Materials and Manufacturing

Industrial linen is produced from flax fibers but undergoes a different manufacturing process compared to traditional flax linen, emphasizing durability and functionality for commercial use. It typically incorporates a blend of flax and synthetic fibers, enhancing strength, stain resistance, and ease of maintenance suitable for hospitality or healthcare industries. The materials used and the mechanized production techniques result in a coarser texture and increased longevity, distinguishing industrial linen from finer, hand-crafted flax linen products.

Fiber Source Comparison: Flax vs Synthetic Alternatives

Flax linen is derived from the natural fibers of the flax plant, offering superior breathability, durability, and biodegradability compared to industrial linens made from synthetic alternatives such as polyester or nylon. Flax fibers exhibit a unique cellulose structure that enhances moisture-wicking and thermal regulation, qualities often absent in chemically-produced synthetic fibers. The environmental impact of flax fiber cultivation is significantly lower, with reduced carbon emissions and minimal reliance on fossil fuels compared to the energy-intensive production of synthetic linens.

Durability and Strength: Flax Linen vs Industrial Linen

Flax linen, derived from the flax plant, exhibits superior durability and natural strength due to its long, resilient fibers that enhance fabric longevity and resistance to wear. Industrial linen, often produced from shorter or mixed fibers and subjected to mechanical processing, tends to have reduced tensile strength and may wear out more quickly under heavy use. The inherent robustness of flax linen makes it ideal for high-quality textiles requiring extended durability.

Environmental Impact: Sustainable Flax vs Industrial Processes

Flax linen, derived from the flax plant, boasts a low environmental footprint due to its natural biodegradability, minimal water usage, and reliance on sustainable farming practices that enhance soil health. Industrial linen production often involves chemical treatments and intensive energy consumption, leading to increased pollution and resource depletion. Choosing flax linen supports eco-friendly textile manufacturing with reduced greenhouse gas emissions and a smaller water footprint compared to conventional industrial linen processes.

Breathability and Comfort: Natural vs Engineered Linen

Flax linen, derived from the flax plant, offers superior breathability and natural moisture-wicking properties, promoting enhanced comfort in warm climates. Industrial linen, often treated with synthetic chemicals or blended with other fibers, may compromise airflow and reduce the fabric's ability to regulate temperature effectively. The natural fibers in flax linen ensure a lightweight, hypoallergenic texture, whereas engineered linen prioritizes durability with potential trade-offs in softness and ventilation.

Aesthetic Appeal: Texture and Appearance Differences

Flax linen is prized for its natural, uneven texture and subtle sheen, offering a more organic and artisanal aesthetic that enhances interior decor with a timeless elegance. Industrial linen, in contrast, typically features a smoother, more uniform surface due to mechanical processing, resulting in a consistent but less character-rich appearance. The tactile quality of flax linen provides a visually dynamic fabric that ages gracefully, while industrial linen's polished finish suits modern, minimalist designs.

Cost Analysis: Flax Linen versus Industrial Linen

Flax linen, derived from the flax plant through traditional processing methods, typically incurs higher production costs due to labor-intensive harvesting and eco-friendly techniques, resulting in premium pricing. Industrial linen, produced on a larger scale with mechanized processes and synthetic additives, offers a more cost-effective alternative with faster turnaround but often compromises on durability and natural texture. Analyzing cost efficiency, flax linen appeals to consumers prioritizing quality and sustainability, while industrial linen targets budget-conscious markets seeking affordability.

Common Uses: Where Flax and Industrial Linen Excel

Flax linen is prized for its natural strength and breathability, making it ideal for high-quality clothing, bed linens, and home textiles that require durability and comfort. Industrial linen, often made from shorter flax fibers or recycled materials, excels in applications like upholstery, canvas, and insulation due to its cost-effectiveness and robust performance. Both types serve distinct markets, with flax linen favored in fashion and luxury goods, while industrial linen dominates functional and heavy-duty textile uses.

Choosing the Right Linen: Factors to Consider

Choosing the right linen involves understanding key differences between flax linen and industrial linen, particularly in fiber quality, texture, and durability. Flax linen, derived from the flax plant, offers superior softness, breathability, and moisture absorption, making it ideal for high-end textiles and garments. Industrial linen, produced through mechanical processes using coarser fibers, is more affordable and suitable for utility applications like upholstery or cleaning cloths.

Flax Linen vs Industrial Linen Infographic

materialdif.com

materialdif.com