Long staple cotton features longer fibers that produce softer, stronger, and more durable fabric, ideal for high-quality textiles like luxury sheets and clothing. Short staple cotton has shorter fibers that tend to be coarser and less durable, often used in lower-cost, everyday products. Choosing between long and short staple cotton impacts fabric texture, strength, and overall comfort.

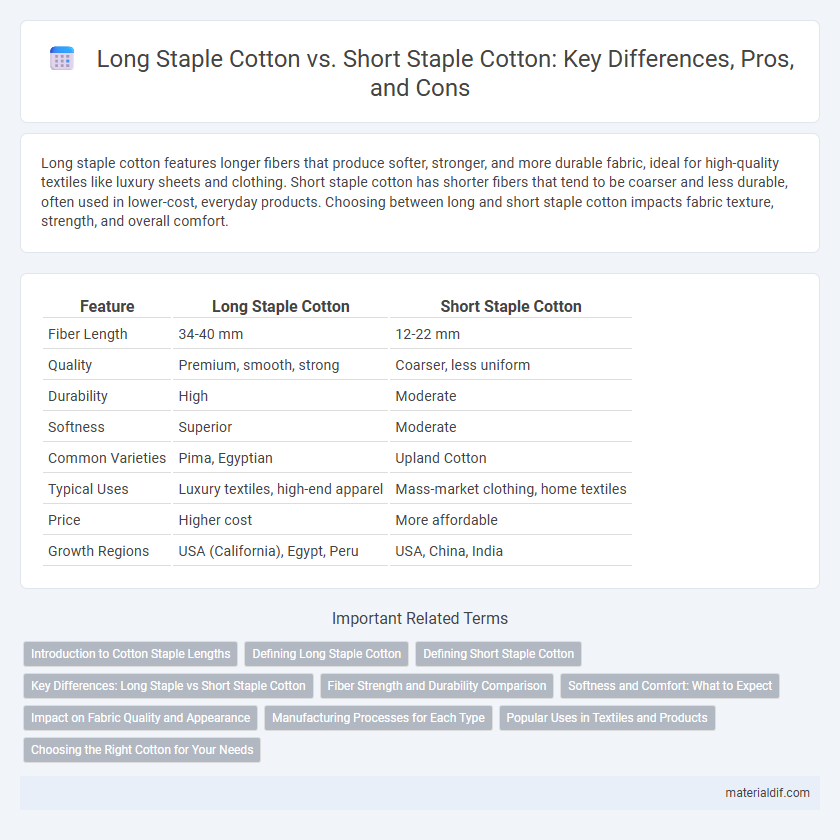

Table of Comparison

| Feature | Long Staple Cotton | Short Staple Cotton |

|---|---|---|

| Fiber Length | 34-40 mm | 12-22 mm |

| Quality | Premium, smooth, strong | Coarser, less uniform |

| Durability | High | Moderate |

| Softness | Superior | Moderate |

| Common Varieties | Pima, Egyptian | Upland Cotton |

| Typical Uses | Luxury textiles, high-end apparel | Mass-market clothing, home textiles |

| Price | Higher cost | More affordable |

| Growth Regions | USA (California), Egypt, Peru | USA, China, India |

Introduction to Cotton Staple Lengths

Long staple cotton fibers, typically measuring over 34 millimeters, provide superior strength, softness, and durability compared to short staple cotton, which usually ranges from 12 to 27 millimeters. Staple length directly influences fabric quality, with longer fibers enabling finer yarns and smoother textiles ideal for high-end apparel and luxury bedding. Understanding cotton staple lengths is essential for optimizing textile performance and selecting appropriate cotton varieties for specific manufacturing needs.

Defining Long Staple Cotton

Long staple cotton refers to cotton fibers that measure longer than 1 1/8 inches, typically ranging from 1.25 to 2 inches, resulting in stronger, softer, and more durable fabric. This type of cotton is prized in textile manufacturing for producing high-quality, luxurious materials such as Egyptian and Pima cotton. In contrast, short staple cotton has fibers shorter than 1 1/8 inches, which yield coarser, less smooth textile products.

Defining Short Staple Cotton

Short staple cotton refers to cotton fibers typically measuring less than 1.125 inches in length, known for their shorter fiber length compared to long staple varieties. This type of cotton is commonly used in producing coarser, more affordable textiles but may result in lower fabric strength and durability. Key regions cultivating short staple cotton include the United States (Upland cotton), India, and China, where it forms a significant part of the cotton industry's production.

Key Differences: Long Staple vs Short Staple Cotton

Long staple cotton fibers, measuring over 1.25 inches, offer superior strength, softness, and durability compared to short staple cotton, which typically measures less than 1 inch. This difference in fiber length significantly affects the quality of fabrics, with long staple cotton producing smoother, finer textiles and short staple cotton resulting in coarser, less lustrous materials. Textile manufacturers prefer long staple cotton for premium products such as Egyptian or Pima cotton due to its enhanced breathability and longevity.

Fiber Strength and Durability Comparison

Long staple cotton fibers, typically measuring 1.5 inches or longer, exhibit superior fiber strength and durability compared to short staple cotton, which generally ranges from 0.5 to 1.25 inches in length. The increased fiber strength in long staple cotton enhances fabric resilience, reducing breakage and wear during manufacturing and in end-use textiles. Consequently, textiles made from long staple cotton demonstrate greater longevity and resistance to pilling, making them ideal for premium clothing and high-quality home textiles.

Softness and Comfort: What to Expect

Long staple cotton fibers are finer and smoother, resulting in softer, more breathable fabrics that offer superior comfort against the skin. In contrast, short staple cotton tends to produce coarser textiles, which may feel rougher and less gentle, making them less ideal for sensitive skin. Choosing long staple cotton ensures enhanced softness and durability, ideal for high-quality clothing and luxury bedding.

Impact on Fabric Quality and Appearance

Long staple cotton fibers, measuring 1 1/4 to 2 inches, produce smoother, stronger, and more lustrous fabrics with less pilling and enhanced durability, ideal for premium textiles. Short staple cotton, typically under 1 inch, results in coarser, less uniform fabrics prone to pilling and wear, which can affect the softness and overall appearance negatively. The fiber length directly influences yarn strength and fabric texture, making long staple cotton the preferred choice for high-quality, luxurious garments.

Manufacturing Processes for Each Type

Long staple cotton fibers undergo a meticulous ginning process to preserve fiber length, followed by specialized spinning techniques that enhance softness and strength, making them ideal for high-quality textiles. In contrast, short staple cotton requires more intensive cleaning and carding to remove impurities and shorter fibers, resulting in coarser yarns suited for durable, everyday fabrics. The manufacturing processes for each type are optimized to maintain fiber integrity and meet specific textile standards in the apparel and home furnishings industries.

Popular Uses in Textiles and Products

Long staple cotton, prized for its strength and smoothness, is commonly used in high-quality textiles such as luxury bedsheets, fine clothing, and durable denim, offering superior softness and durability. Short staple cotton, with its shorter fibers, is typically used in everyday products like towels, basic apparel, and cotton balls, providing affordability and versatility despite a coarser texture. Both types of cotton play crucial roles in the textile industry, catering to different market segments based on fiber length and fabric quality requirements.

Choosing the Right Cotton for Your Needs

Long staple cotton fibers, such as Egyptian and Pima cotton, offer superior strength, softness, and durability, making them ideal for luxury bedding and high-quality apparel. Short staple cotton varieties, like Upland cotton, are more common and cost-effective, suitable for everyday textiles and mass-produced garments. Selecting the right cotton depends on the desired fabric feel, durability, and budget considerations, with long staple cotton providing premium quality and short staple cotton balancing performance and affordability.

Long Staple Cotton vs Short Staple Cotton Infographic

materialdif.com

materialdif.com